Dishwashers have long been among the indispensable household appliances. The opportunity to free up free time by entrusting dishwashing to a machine attracts many. However, users often encounter incorrect operation of the equipment. Usually it is the pressure switch that breaks. Therefore, it is important to know how to replace the water level sensor in a dishwasher.

Dishwashers have long been among the indispensable household appliances. The opportunity to free up free time by entrusting dishwashing to a machine attracts many. However, users often encounter incorrect operation of the equipment. Usually it is the pressure switch that breaks. Therefore, it is important to know how to replace the water level sensor in a dishwasher.

What is the function of the water level sensor in a dishwasher?

A specific feature of competent production of dishwashers is the use of an acceptable volume of water, without compromising the cleaning performance of the dishes. This point will be obvious to many. After all, other parameters will also influence the degree of purification efficiency.

It is not so much the volume of liquid spent that will affect the quality of washing, but the temperature at which washing is carried out. Efficiency will directly depend on spray technology. If for some reason the machine takes on too much fluid, performance may drop.

The spraying technology will be disrupted due to increased hydraulic resistance. In addition, energy consumption will also increase, because a larger volume of water requires more powerful heating.Time costs will also increase several times. The dishwasher will work much longer due to the longer heating of the water.

Therefore, manufacturers began to equip their models with a water level sensor. Its role is difficult to overestimate, because the presence of the part in the equipment design ensures proper water intake. The pressure switch monitors the required liquid level in the tank and controls all changes in volume.

Unfortunately, sensor failures are not uncommon. Usually a part works correctly only the first time after purchase. And then during operation, improper water intake begins to appear. The basis of all failures that occur is the incorrect operation of the pressure switch.

Moreover, the point is not at all in the low quality of the spare part. The origins of the problem lie in the water used to operate the dishwasher. As a rule, the composition includes suspended substances, and in high content. If water of this quality is used for a long time to operate the machine, then rapid wear of spare parts is inevitable.

Unfortunately, centralized water supply rarely allows the use of high quality water. Typically, the liquid flowing from a tap contains a large amount of impurities. And low water quality leads to breakdowns of plumbing and household appliances. Water level sensors can be cited as confirmation.

Types of water level sensors

The following types of sensors are distinguished:

- Mechanical. Diagnosing a part of this type is quite simple; the relay membrane will indicate a malfunction. Damage to it will indicate the need to replace the part. Usually small holes that cover the membrane lead to improper water intake.Water leaks through the holes, causing the dishwasher to malfunction.

Problems with the sensor may also be indicated by the absence of function switching sounds. If the machine makes a soft clicking sound when you turn on the modes, then the part is in good condition. If, when switching programs, no accompanying sounds are heard, then the part requires replacement. In this case, you can try to restore the operation of the device, since the malfunction may occur due to sticking contacts on the relay. - Electronic. Such a part changes the operating mode using an electronic type design. Moreover, it works under low voltage conditions. The main spare parts are a hose and a reservoir. Relays and switches are not installed, as their function is performed by the electronic board.

If a breakdown occurs, the dishwasher displays an error code on the electronic display. Please note: when carrying out diagnostic procedures, do not use high voltage equipment.

Any type of sensor can fail. However, if a malfunction occurs, it is necessary to replace it as soon as possible.

Working principle of the water level sensor

Features of the functioning of the pressure switch depend on its type. The operating principle of a mechanical sensor is based on the transmission of water pressure. The poured liquid presses on the silicone membrane, the force is transmitted to the contact device through the rod. And there, under the influence of pressure, the contacts responsible for regulating the volume of water close.

Often, malfunctions are explained by a malfunction of the membrane, which is damaged. As a result, the sensor reads water pressure worse, and the lack of force leads to incorrect water intake.Physical damage usually occurs due to a missing filter when impurities from the water supply enter the machine. Mechanical type sensors usually use relay control.

Electronic type pressure switches have similar operating characteristics. Relay components are not used only to control the volume of liquid in the tank. Manufacturers use semiconductor-type elements to ensure switching between cleaning programs.

Using an electronic device to provide control has undeniable advantages. Diagnostic procedures are carried out automatically. There is no need to disassemble the machine to find out the cause of the problem. If problems have been reported, the user will receive an error message.

Electronic devices are much easier to manage and diagnose. You can find out the type of failure by the error code, the explanation of which is in the user manual. However, repairing such devices is much more difficult and more expensive. It will be very difficult for a user who does not have the skills to repair dishwashers to fix problems on their own. In this case, it is better to seek service assistance and pay a specialist to fix the problem.

How to check the serviceability of the pressure switch

Some signs will indicate a malfunction:

- interruption of water supply;

- when starting, the machine pumps too much or too little liquid through the hose;

- the equipment stops, and the tank remains full, since the draining process does not occur;

- After pumping the liquid, the machine immediately starts draining.

If fluctuations in the liquid level do not correspond to the specified programs, then we can talk about a breakdown of the sensor. The main causes of the malfunction include:

- damage to sensor parts;

- the manufacturer decided to save money by installing a spare part of poor quality and at a cheap price;

- The service life of the pressure switch has expired, wear has caused malfunctions;

- the oxidation process began, which affected the connecting contacts.

The dishwasher reservoir affects the pressure switch membrane. This happens through water poured to the desired level. The filled bath presses on the membrane, which, in turn, activates the rod, which moves the switch contacts. If a malfunction is suspected, the low level relay must be checked. This is done by ringing the contacts with collected water and an empty tank.

Algorithm of actions:

- The dishwasher must be turned off from the power supply.

- Then you need to open the panel through which control is carried out.

- Using the equipment diagram provided by the manufacturer, locate the relay conductors. If you couldn’t find a diagram in the documents, go to the manufacturer’s website. Usually brands post all the documentation for their model range.

- Now you need to check the resistance between the conductors. To do this, use an ohmometer, it will allow you to take measurements.

- If water is flooded and the tester shows no contact, then the sensor is broken. If the measurements showed the presence of contact in the presence of water in the pan, then the pressure switch is working normally.

- If measurements are taken in the absence of water, then the presence of contact will indicate a malfunction. If liquid was not poured into the pan, then the tester should not register contact.

In a similar way, you can check for faults in the upper level conductors. In this case, you will also need a dishwasher circuit, and all actions will be carried out through the control panel.You only need to identify the conductors on the board coming from the upper level switch. The test is carried out sequentially with the tray empty and filled with liquid.

How to replace the pressure switch in a unit

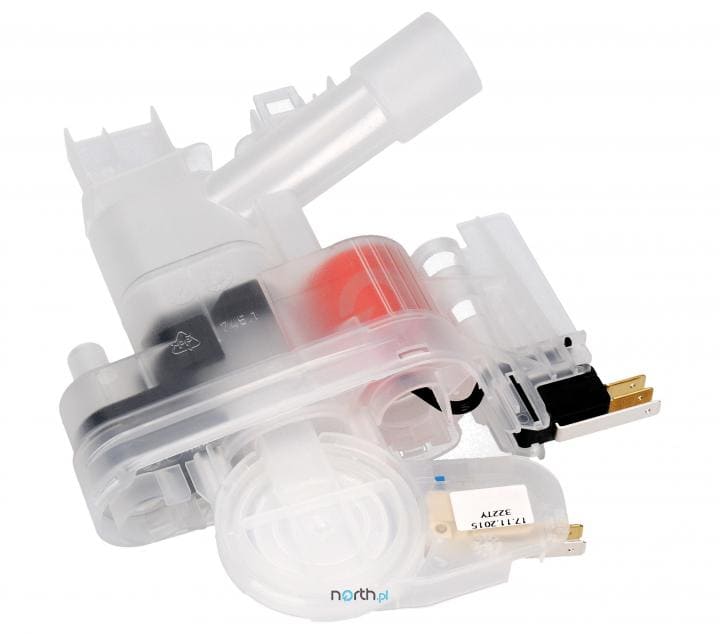

If malfunctions in the operation of the sensor are detected or its breakdown is determined, then the part will need to be replaced. Spare parts of this type cannot be repaired, so you will have to buy a new pressure switch. However, before this you need to find out the sensor model, and this can only be done by disassembling the device.

You will not be able to solve the problem by installing a part from another dishwasher. Even within the same brand, the spare parts used may differ. To restore the dishwasher to working order, you need to select a complete replacement for the damaged sensor.

Therefore, disassembling the dishwasher is necessary in any case, since you will need to determine the brand and model of the supplied part. You can carry out the process yourself, or you can entrust it to a specialist. The service center will quickly disassemble the washing mashine and remove the defective part.

The sequence of actions will differ from brand to brand. However, we can describe the general principle of disassembling a dishwasher. During the process you will need an adjustable wrench and a screwdriver. You need to do the following:

- The device must be disconnected from the power supply and the hoses connecting to the water supply and sewerage system must be removed.

- It is necessary to clear the area for analysis. Moreover, the unit will be located on the rear back, so a lot of space will be required.

- Equipment disconnected from communications must be placed “on its back.” To insure against damage, you can place a blanket under the washing mashine.

- Now you need to dismantle the bottom cover.To do this, you need to remove the screws holding it in place and unfasten the latches.

- If the float sensor is fixed to the pan, you need to remove the bolts holding it in place. Conducted wires also require careful disconnection.

- Having completed all of the above steps, the user will see a plastic box with a tube coming from it.

- The tube must be removed using pliers. After disconnecting the part from the bath, check the latter for contamination.

- Now it is necessary to diagnose the sensor and its mechanical side. This is easy to do: you need to blow into the pressure tapping tube. Then you need to listen, if the device is working properly, the switch will operate and clicks will be heard. Usually the recoil is heard almost immediately, the sounds will be heard after a few seconds.

- The next stage is diagnostics of the electronic component. A multimeter will help you register problems; to carry out the test, probes are attached to the contacts. The operating state of the pressure switch will be indicated by a value equal to zero.

- If, as a result of diagnostic measures, a breakdown is identified, the sensor must be replaced. Moreover, if contact between the terminals has been registered, but it is unstable, then another part needs to be installed.

- After the dismantling and installation of another spare part has been completed, assembly is required. All disconnected wires, fasteners and spare parts must be reinstalled in reverse order.

- After assembling the dishwasher, you need to put it in its original place. And then connect to all communications.

- The final stage is a performance check. To do this, run the dishwasher in test mode. If the water is collected in the correct volume, then the replacement was successful.

Replacement of the part with an original one should also be done for practical reasons. Original spare parts will match the parameters of the dishwasher, which will ensure a long service life. Periodic cleaning of the drain from contaminants will also help prolong the operation.

You should not ignore the rules of use described in the manufacturer’s manual. It is much easier to keep your dishwasher in working order using simple rules than to spend money on repairs and installing new parts.

Dishwasher repair tips

Specialists with extensive experience in carrying out repair work have prepared recommendations for inexperienced users:

- Read the instructions. Any troubleshooting work should begin by reading the user manual.

- Take notes or record the dismantling process using video. There is no need to be shy about shooting video or recording details; the design of each model has its own nuances. The abundance of spare parts can be a serious problem, since it is difficult to restore the installation sequence from memory. It can be easy to get confused about the order of actions or the position of certain parts.

- Do not change the assembly steps. It is necessary to install previously dismantled parts in strict order. The sequence of actions will allow you to avoid mistakes.

- Prepare a box for small parts. In order not to lose an important spare part, it is better to put them in a separate place.

- It is better to lay out the removed parts in the order of dismantling. This will reduce assembly time.

- Be careful. Many spare parts are made of lightweight material. Therefore, careful handling is extremely important, otherwise you will have to spend money on new parts.

- Do not waste energy on repairs if the new part is “disposable” in nature. In this case, the problem can only be resolved by replacing the faulty spare part.

Nowadays, many brands use parts in the production process that require complete replacement. Many spare parts cannot be repaired. One of these parts is the water level sensor. If a breakdown has been diagnosed, you will have to buy a new spare part.

Fortunately, you don’t have to spend money on calling a repair specialist, since even an inexperienced user can replace a mechanical pressure switch. However, electronic sensors have a more complex structure, so if such a part breaks down, you should seek service support.

Water with a large percentage of impurities causes sensor failure. Therefore, the best way to ensure long-term operation of the dishwasher is to install a filter.