A front-loading plate washer is used in restaurants, cafes and other catering establishments with a large number of dining areas. The MPK 500F dishwasher has one important difference: within one hour of operation it can wash up to five hundred dishes. This high-speed operating mode makes it possible to ensure timely washing of dishes at any large enterprise.

A front-loading plate washer is used in restaurants, cafes and other catering establishments with a large number of dining areas. The MPK 500F dishwasher has one important difference: within one hour of operation it can wash up to five hundred dishes. This high-speed operating mode makes it possible to ensure timely washing of dishes at any large enterprise.

Technical characteristics of MPK 500F

For normal operation of the MPK 500F dishwasher, a power of 6.6 kW and a voltage of 400/230 V will be required. Eighteen plates, thirty-six glasses, and one hundred and forty cutlery can be loaded into one cassette.

The machine has two working programs - main (2 min) and additional (3 min). During one working cycle, water consumption is no more than two liters.

The water temperature is:

- washing solution – 40 degrees;

- when rinsing – 85;

- in the water supply network – 5.

Boiler capacity – 5.7 liters, bath – 23.5.

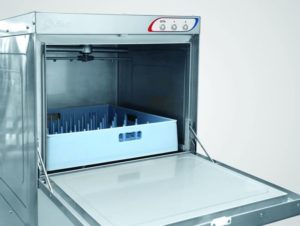

Features of the MPK 500F device

The washing bath contains:

- a filter element that protects the pump from clogging with food waste;

- an overflow tube that drains excess liquid into the sewer system;

- riser for attaching washing and rinsing sprinklers;

- sensor that controls water level;

- temperature sensor;

- water heating device.

The bathroom has special guides. In which cassettes loaded with dirty dishes are installed. Below the sink compartment there is a control panel.

The body of the dishwasher is covered with a lining, all panels are removable, which facilitates the process of inspection and maintenance of the MPK 500F.

An electric pump is installed under the bathtub. There is also a boiler, an electromagnetic valve, an electrical panel, and a dispenser for rinse aid.

For ease of use, the panel contains:

- network button with green indicator;

- two buttons with red backlight, with which you select one of the two available operating modes;

- a controller responsible for the presence and supply of liquid to the bath, regulating the temperature of the water, controlling all pumps, setting the automatic operating mode according to the established program, automatically stopping the operation of the unit when the door is opened and continuing it again after closing.

The presence of water in the MPK 500F dishwasher is controlled by submersible electrodes. If there is not enough liquid, the controller signals the valve, which turns on and allows water to flow.

Workflow Stages

There are three of them in the MPK 500F dishwasher:

- washing - the pump activates the washing solution, delivers it from the bath to the sprinklers, which direct the liquid onto the dirty dishes;

- exposure - the remains of the detergent composition must completely drain from the washing elements and from the walls of the dishes;

- rinsing - the solution is supplied from the boiler to the spray devices.

Installation rules

As follows from the operating instructions, the MPK 500F dishwashing unit must be unpacked, installed and tested by experienced specialists.

The machine is placed in a spacious room with a good ventilation system. Installation is performed in a certain sequence:

- The packaging material is removed from each element;

- the dishwasher is placed in the place designated for its installation;

- height adjustment is carried out using the adjustable feet. Correct installation is checked by level;

- MPK 500F is connected to the water supply network, sewerage, and electricity. Grounding is arranged;

- connecting elements are checked;

- installation work is checked by a test run without laying the dishes. The process is performed at least five to six times to remove all the composition used to preserve the unit.

Operating rules for MPK 500F

Dirty dishes are placed in cassettes. The quality of the wash will depend on how quickly after the dishes arrive from the dining room they are loaded into the dishwasher, after removing the remaining food.

After filling, the water opens, the machine is plugged in, and visual monitoring of the presence of detergent and rinse aid is carried out. Hoses carrying liquids must be immersed in appropriate containers.

On the panel, click the “Start” button. If the indicator is flashing, the dishwasher is preparing to start the operating process.

As soon as the washing is completed, all buttons blink with indicator lights. Cassettes loaded with washed dishes are removed, the next process is activated after you slam the door of the MPK 500F.

After every three hours of use it is recommended:

- turn off the dishwasher;

- drain the liquid from the bath by removing the filter mesh;

- remove food debris, rinse the bath, tube and filter with running water;

- After this, all the elements are installed in their places, the machine is turned on for further work.

Conclusion

Front-loading dishwashers have proven themselves in catering establishments. It is distinguished by its reliability, ease of maintenance, and reasonable price.