An automatic washing machine is now found in almost every modern home. This irreplaceable assistant works tirelessly for years, but sooner or later, like any other equipment, it begins to fail. If problems arise at the stage of pumping or draining water, most likely the drain pump has become unusable. It is this that ensures the normal operation of the entire device. The pump for a washing machine is one of the main technical components, which is directly involved in every stage of washing.

Types of pumps in a washing machine

Washing machine repair specialists claim that the original factory pump, subject to normal operation, lasts on average at least 10 years. Premature problems can arise due to lack of proper and timely care of the part, as well as simple clogging with small metal debris and various technical impurities in the water.

In some cases, the pump can be repaired, but sometimes it has to be replaced completely. Then the question arises of choosing a suitable pump. It should be approached with all responsibility, since the complexity of the installation and further operation of the equipment depend on it.

There are more than 50 types of pumps in automatic washing machines. For convenience, they can all be divided into two main types:

- drain - used in budget or outdated versions of machines. A simple mechanism drains water into the drain after each wash cycle;

- circulating - they supply water to the washing zone and circulate it along a closed path in one direction only. Most often, they work in tandem with a conventional pump to increase efficiency. This significantly improves washing efficiency.

A more detailed classification is considered in accordance with the following characteristics:

- fastening method - there are options with latches, screws, and combined, when the previous two types are combined;

- according to the characteristics of the contact connections - there are pumps with terminals that go in the opposite direction from the impeller, behind it and “under the chip”. In the latter version, the connector has a rectangular shape, and the connections are parallel to each other;

- power - the average value ranges from 15 to 100 W. If there is insufficient power, the device is not able to perform the job fully. Most models have a power of 34-40 W. In old units, high-power pumps were very large and expensive to manufacture, but modern pumps with higher power are distinguished by their completely small sizes;

- number of branches - standard or branched.The latter is a kind of tee, one outlet is directed to the sewer, the other to the sink, and the third is connected to the washing machine. For residents of multi-storey buildings, a siphon with a check valve is considered a good option. It blocks the return of liquid to the machine if the drain hose is clogged;

- shape and size - more modern varieties are compact and well thought out. They take up very little space while maintaining excellent functionality. For example, the now popular powerful synchronous pumps with a magnetic rotor are very small in size.

The question of the manufacturer remains no less important. The highest quality and most modern pumps are produced by Italian brands Askoll and Plaset. Their products are used in more than half of all washing machines produced in the world. Besides these, Mainox, Hanning, Artiko and CopreciGre are also well known.

Undoubtedly, it is best to give preference in choosing a complete analogue of the original pump. It will fully comply with the technical parameters of the device and will not cause additional problems when connecting. It will be enough to simply restore all connections as they were before the intervention.

Pump operating principle

The drain pump is directly involved in every stage of washing. It pumps out excess water during rinsing and spinning, and also drains dirty water after the cycle is completed. It follows from this that the pump takes an important part in all stages of the device’s operation. Next, let's look in more detail at how this happens.

After selecting a washing program, the moment you press the “Start” button, water is automatically drawn in.The pump is activated by signals it receives from the electronic module. The pump's solenoid valve opens, and a special water level sensor controls the required amount. The path of the supplied water is laid in such a way that it mixes with detergents from the tray, dissolves them and fills the washing machine tank with soapy water.

Liquid drainage begins through a rubber pipe connecting the tank to the volute. Then it enters the pump through a special filter, which reliably protects the impeller from clogging. This point is very important, since even small debris can lead to jamming.

The water then flows away through a drain hose attached to the volute. The process of pumping out dirty water continues until it is completely finished. Here it is worth paying attention to one very important point: the end of the drain hose must be secured slightly above the drain pump, otherwise the water may drain by gravity. It is recommended to install it at least 80 cm.

Signs of a faulty drain pump

You can distinguish a drain pump breakdown from other types of malfunction by the following main characteristics:

- During normal operation of the washing machine, water is pumped out very slowly.

- Lack of response to programs.

- Small volume of water in the machine tank.

- The device makes a lot of noise or crackles when pumping or draining water.

- The pump makes a loud noise, but no water comes out at all.

- During the draining process, the pump automatically turns off.

If at least one of the above symptoms is present, it is necessary to urgently diagnose the drain pump.It may be necessary to simply clean the clogged parts, and the operation will be completely restored.

Also, the occurrence of a breakdown is reported by service codes, which can be deciphered on the manufacturer’s website or in the accompanying instructions.

In order to correct the breakdown, it is necessary to inspect the drain pump and figure out what exactly led to this malfunction. The options may be the following:

- clogging of the drain system: filter, pump or pipe;

- clogged sewer system;

- no voltage on the pump - occurs when the engine malfunctions or other defects in the supply of electrical contacts occur;

- damage to the rubber or plastic seal - occurs as a result of the accumulation of dirt and scale on the impeller of the device;

- destruction of the impeller - accompanied by extraneous sounds when the wash starts;

- short circuit or break in the winding;

- the motor bushings are worn out;

- the pump runs continuously - occurs as a result of incorrect connection or malfunction of the water level sensor.

Location of the drain pump and how to get to it

A broken washing machine can be sent to a service center for diagnosis and repair, but if you wish, you can deal with the problem on your own. Depending on the distinctive features of the model, the pump may be located in different places of the machine. The general instructions in this situation recommend the following sequence of actions:

- De-energize the washing machine by unplugging it from the outlet.

- Shut off the water supply.

- Turn the device over so that the drain is on top.

- Unscrew and remove the top cover. Usually the drain filter unwinds several turns.

- Place a container prepared in advance for the remaining water.

- Clean the filter mesh from accumulated debris.

After performing these simple manipulations, it becomes possible to examine in detail the internal mechanism of the equipment, since all the parts are located at the bottom of the device. For convenience, it is better to illuminate with a flashlight. If necessary, the impeller should be cleared of debris and try to carefully rotate it by hand - ideally, it should rotate with slight delays.

The easiest to inspect machines are those manufactured by Electrolux, Samsung, Candy, LG and Zanussi. Typically, their diagnosis is carried out through the bottom or by removing the rear panel. But Indesit, Siemens and Bosch lose in this matter - all the most important parts are located under the front cover of the machine. In such cases, you first need to remove the loading hatch, which is a rather lengthy and labor-intensive process.

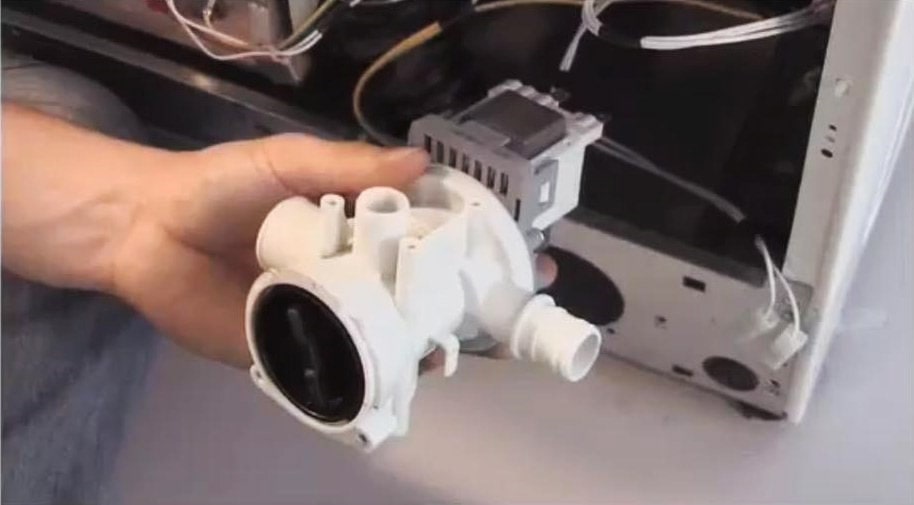

How to remove the pump yourself?

The progress of the task may differ depending on where access will be made: through the bottom, rear panel or front.

In order to dismantle the pump through the bottom, you will need to perform the following steps:

- Tilt the washing machine body back or lay it on its side. It is better to lay a blanket so as not to scratch the surface of the equipment.

- Many machines come without a bottom, but if there is a bottom cover, it must be removed. You must act carefully, since a water leakage sensor may be placed here. It must be turned off and the fixing screw unscrewed.

- Next, place a flat container and unscrew the pump bolts.

- After this, they proceed to loosen the clamps, remove the pipes and hose.

- Remove the wiring.

- The pump is dismantled and replaced.

To perform dismantling through the front panel, proceed as follows:

- Unscrew the screws of the top cover of the panel, move it slightly back and remove.

- Remove the detergent tray. To do this, you usually need to lightly press the middle latch in the center. Depending on the model and manufacturer, this item may differ slightly.

- Unscrew the control panel latches and move it away. You don’t have to disconnect the wiring; you just need to put it on top of the machine body.

- Open the hatch door and bend the rubber seal. The clamp is pryed up with a screwdriver and removed.

- Unscrew the bolts that are responsible for fixing the door lock.

- Disconnect the UBL wiring.

- Loosen the fastening of the front panel, carefully lift it and remove it.

- Removing the pump occurs in exactly the same way as in the previous description: the fasteners are removed and access to the pump is opened.

Washing machines, in which access to the internal mechanism is provided through the back cover, have a special design. Their body consists of a non-removable bottom and two integral parts. Therefore, you should proceed according to the following instructions:

- remove the top cover by first unscrewing the fixing screws;

- remove the inlet valve that is attached to the rear wall;

- if the bolts that secure the sides are hidden behind plugs, they must be carefully pryed off with a flat screwdriver;

- unscrew the bolts;

- Carefully slide the back cover back.

After completing the work, the equipment should be assembled in the same order. Taking this opportunity, you can clean the hose and pipe from debris. If the clog is caused by a clogged drain, you should call a plumber immediately.

DIY pump repair

Anyone can repair the pump themselves. You just need to carefully study the nature of the breakdown and arm yourself with the necessary tools.

If the problem is caused by a burnout of the electrical winding, the drain pump needs to be completely replaced. In most other situations, it is still possible to restore the functionality of this important element.

First, you should disassemble the pump housing to clean the impeller and filter. Typically, the two halves of the device are fastened together with three screws, which can be easily unscrewed.

Large debris in the form of hair, threads and hairballs can impair the operation of the mechanism. Accordingly, if such contamination is discovered, it must be removed immediately. As for the inner surface of the snail, it should be wiped with a wet cloth to remove deposits of washing powder and rinse aid.

After this, the two halves must be carefully rinsed with water, preventing drops from entering the engine. Upon completion, you can assemble the case, connect the electronic terminals, pipes and install all the parts in their original places.

To check the operation, the assembled machine is turned on to the rinsing mode and the operation of the drain mechanism is monitored. If the problem cannot be resolved, you will have to completely replace the pump with a new one.

One of the many causes of pump malfunctions may be loose contacts or faulty sensors. You can detect the problem area by “ringing” the wires using a multimeter.

It is recommended to inspect the integrity of the pump once every three months.

Replacing a faulty pump with a new one

To replace a broken pump, it is not necessary to seek the services of a specialist.You can do the work yourself, following the recommendations described above. This is not at all difficult, the main thing is to take precautions and install the terminals and connections in the same way as they were placed before.

To carry out the work, you will need a complete drain pump, impeller, cuff, axle, pulley, sensor, all necessary contacts and gasket. The tools used are a Phillips screwdriver, a knife and a multimeter to measure voltage.

Replacing the pump on a top-loading washing machine

The top-loading machine design allows access to internal parts through the rear cover. In this case, you must act very carefully, since there are boards and functional parts on it. Otherwise, the step-by-step execution of the work fully corresponds to the “horizontal” models:

- Unscrew the screws along the edges of the cover and remove it;

- remove all the bolts that are responsible for fastening the rear panel;

- If it is necessary to remove the side wall, you must also first unscrew the bolts. They can be in front or behind the machine body;

- Unscrew the pipe clamp on the drain; if it is secured with a screw, it should also be unscrewed;

- disconnect the pipe and all wiring connectors;

- remove the outlet valve and drain the water;

- Unscrew the screws that secure the pump and remove it. Install a new part;

- connect the contacts and put everything back together.

Replacing the pump on washing machines of German brands

Well-known German manufacturers such as AEG, Kaiser, Bosch, Miele and Siemens are renowned for their durability and excellent performance. But if a problem occurs with the drain pump, getting to it is not so easy.To do this, you must strictly follow the following instructions:

- Unscrew the two screws from the back, slightly move the top cover forward and remove it.

- Carefully remove the detergent tray, taking into account its design features.

- Unscrew all the screws located around the perimeter of the panel. Unfasten the plastic latches using a flathead screwdriver or any other convenient tool.

- The disconnected panel can be carefully removed to the top without disconnecting the wires, or hung on a special service hook.

- Unfasten the latches of the lower plinth panel, which is located under the hatch.

- Open the hatch door, bend the rubber cuff, pry the clamp with a screwdriver and remove it. For convenience, the cuff should be tucked inside the tank.

- Place your hand behind the body in the place where the hatch lock is located and disconnect the wiring.

- Unscrew the fasteners that hold the front cover of the machine, slide it and remove it. Then access to the pump is open. In some washing machines, the drain pump can be removed by turning it counterclockwise.

Rules for operating the washing machine pump

This part is designed to last for many years, but mishandling, bad water and electrical failures can significantly shorten the lifespan and cause premature failure. There are known cases when this kind of malfunction occurs already in the first three years of operation of the device.

You can maximize the safety of your equipment and extend its service life by adhering to the basic rules for operating the equipment. These include:

- Items that are too dirty must be shaken out first and, if necessary, rinsed before loading into the machine.This useful habit will rid your washing mashine of a large amount of dirt and debris that settles on its internal parts;

- wash with powder intended for automatic washing machines. Observe the correct dosage, since excess can also clog the drain channels of the machine;

- use special bags for washing things with beads, rhinestones, small buttons and other decorative elements that can come off during the washing process and get into the machine mechanism;

- carefully check the pockets of things before loading: coins, threads, pieces of paper and other debris can clog the filter and lead to jamming of the impeller;

- If possible, install purification filters that allow you to supply already purified water to the machine. In regions with poor quality water, a filter is often installed for the general water supply to the house. This will not only protect the washing machine, but will also generally have a positive effect on many aspects of everyday life.

It is imperative to carry out regular preventative checks of the device, which includes inspecting the pump, impeller and wiring, and cleaning the drain hose.

A failure of the washing machine pump affects the operation of the entire device as a whole. You can deal with the problem by contacting a service center or yourself. Depending on the design features of the equipment, ways to solve the problem may differ slightly. In order to extend the life of this critical part, you should check the pump every three months, limit the entry of debris into the machine and use detergents in accordance with the instructions.