Conclusion

Conclusion

To have your own energy source on your home site, it is not necessary to buy it. A good solution would be a wind generator from a washing machine, which you can make yourself. To make it, you will need old household appliances, a number of additional parts, free time and detailed instructions.

Features of a wind generator from a washing machine

A branded wind generator, even purchased in one of the Chinese online stores, costs at least seventy thousand rubles. A homemade wind turbine made from a washing machine engine will cost the owner significantly less. Its manufacture will require a lot of free time, as well as a number of efforts, but the result is worth all the costs.

At the same time, you do not need to think that the stronger the wind, the higher the performance of the wind generator. When wind gusts reach a speed of 25 m / s, the wind turbine generates much less electricity due to the fact that the blades are perpendicular.

The benefits of homemade wind generators from a washing machine engine depend on the amount of electricity they produce.How to make a wind generator from a washing machine - washer.tomathouse.com

Repair

Wash

Dishwashers

- Purchase

- Accessories

- Miscellaneous

- Reviews

- Home page

- Accessories

- How to make a wind generator from a washing machine

- CONTENT

- Features of a wind generator from a washing machine

- Preparing for the manufacture of a wind generator

- Rotor

- Mast

Gearbox

Impeller

How to make a wind generator

Conclusion

To have your own energy source at home, it is not at all necessary to purchase it. A good solution would be a wind generator from a washing machine, which you can make yourself. To make it, you will need old household appliances, a number of additional parts, free time and detailed instructions.

Features of a wind generator from a washing machine A branded wind generator, even purchased from one of the Chinese online stores, costs at least seventy thousand rubles. A homemade windmill made from a washing machine engine will cost the owner significantly less. Making it will require spending a lot of free time, as well as a lot of effort, but the result is worth all the costs.

- The device must be installed in an open space, and for effective operation it requires a wind blowing with a force of 9-10 m/s.

- At the same time, you don’t need to think that the stronger the wind, the higher the performance of the wind generator. When wind gusts reach 25 m/s, the windmill produces much less electricity due to the fact that the blades are perpendicular.

- The benefits of homemade wind generators from a washing machine engine depend on the amount of electricity they produce.0.2 kW of electricity received from such a device will illuminate a couple of rooms and allow you to turn on the TV. With a windmill output of up to 5 kW, the owner will be able to use a washing machine, refrigerator, and computer. A power of over 20 kW will allow you to not only illuminate, but also heat the entire house, as well as work with all available electrical appliances.

- The washing machine engine allows you to assemble a device with a performance of up to 2.5 kW.

Preparing for the manufacture of a wind generator

To assemble a wind generator from a washing machine engine, you first need to prepare its components.

Rotor

The key part of any wind turbine is the electric generator. It can be made from the motor of a Vyatka, Oka, LG washing machine or any other domestic or foreign model. The difficulty is that the engine rotor will need to be completely redesigned. This is a long, complex and very painstaking procedure, instead of which you can purchase a new magnetic rotor.

To modify an existing motor assembly, you will need to cut it correctly using a lathe, and then make grooves for installing magnets. Next, you will need to purchase new neodymium magnets. Their price is equal to the cost of a new rotor. No mistakes are allowed when installing magnets.Any, even the slightest, shift to the side will lead to sticking of the magnets and a significant decrease in the performance of the future design; in the worst case, the device does not produce any current at all. Therefore, they need to be installed and secured as accurately and firmly as possible.

The engine rotor is the main and most expensive part of a wind generator. Its cost with delivery can reach two to three thousand rubles.

If you still want to make a generator with your own hands, you need to:

- Take an old direct drive motor and pull out the rotor.

- Using a lathe, cut off the old core by about 2 mm.

- Make grooves on the rotor for magnets 5 mm deep.

- Make a template for attaching magnets from a sheet of tin. It should fit very accurately and tightly. You need to make markings on it to install additional parts in two rows at an equal distance from each other.

- Purchase neodymium magnets online or in a specialty store. It is necessary to buy an even number to alternate poles.

- At the same angle, at the same distance, in order to achieve maximum magnetic field density, attach them to the core by cold welding or epoxy resin. You can also use superglue.

- Knead the cold welding so that it feels like plasticine to the touch and fill the space between the magnets with it.

- Secure the assembled part to the motor with glue and sand it with sandpaper.

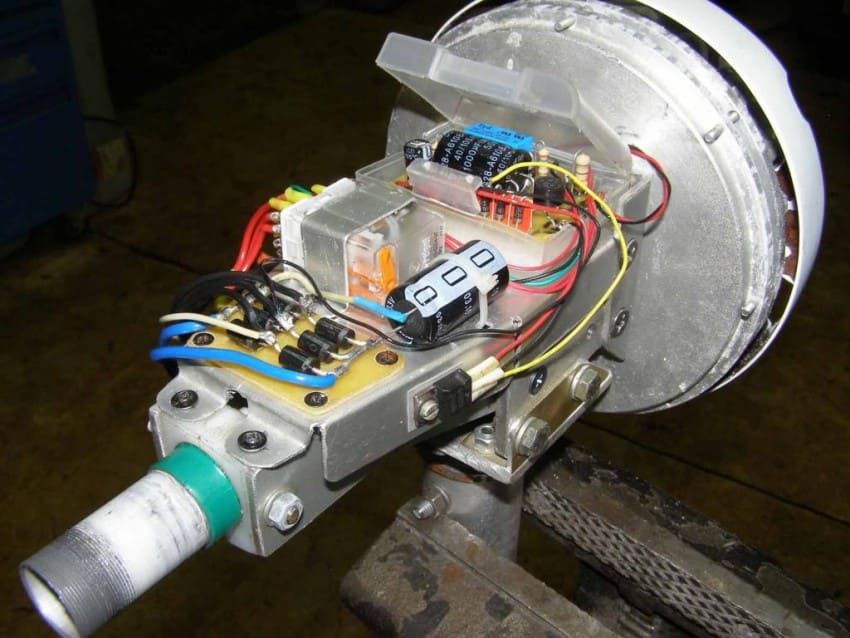

To check the assembled generator, you need to connect the wires leading to the working winding of the engine to the rectifier, and the latter to the controller connected to the battery.

If everything is done correctly, the voltmeter will show a voltage of 250 to 270 Volts at the battery contacts. If the voltage is very low, this means that the magnets are installed incorrectly and the design needs to be redone.

You also need to make sure that the magnets do not stick during operation.

If no problems are found, the homemade generator from the washing machine engine is ready for use. In addition to the generator, the future wind turbine consists of such elements as a mast, gearbox, impeller, shaft, flange and gears., Mast, The mast can be made from scrap materials. A long pipe works great, but if you don't have one, you can use sections of different pipes. They need to be welded together to get a mast ten meters long. The manufactured mast must be painted white and installed in a vertical position. You can use a pole or other object as a support. The only condition is that it should not interfere with the rotation of the windmill., Gearbox, The purpose of this part is to protect the wind generator from damage during strong gusts of wind. It controls and reduces the speed of the windmill propeller. , To assemble the gearbox, you need:, Take the drive gear from the old water pump and put it on the mast., Attach axles - pieces of metal reinforcement - around the perimeter by welding.Attach bearings and gears to the axles and press them into place. Place another small gear on the mast.

All gears are in close contact and interact with each other.

- The gearbox must be reliably protected from bad weather conditions, so it is recommended to provide a housing for it. It can be taken from a water pump or an electric motor.,

- Impeller

- Another important part of the windmill is the impeller.Its blades can be winged or sail-shaped, like on windmills. It is better to make winged blades, because... they have better efficiency. Their length should be from one and a half to two meters, they can be made from light but strong material. Wood, plastic or aluminum work well.

- Additionally, a propeller can be made from a sheet of fiberglass. In this case, in order for the structure to be rigid, the workpieces must consist of two layers. After this, they will be connected into a single device.

- Once the manufacturing of the parts is completed, you can begin assembling the wind generator.

- How to make a wind generator

- To assemble a wind generator from a washing machine engine with your own hands, you need to carefully follow the step-by-step instructions.

- First you need to install the support and mast. This should be done in an open area, preferably on a hill. The windmill should be installed in calm, windless weather.

- After installing the support, you should attach the propeller and gearbox to it.

- To prevent moisture from getting on the generator and rotor, it is necessary to construct a protective casing for them. To prevent equipment from being damaged by frost, it is necessary to cover it with silicone grease for the winter.

- Now you can connect the generator to the mains to test how it works.

- Conclusion

- You can make many useful devices from the engine and body of an old washing machine: