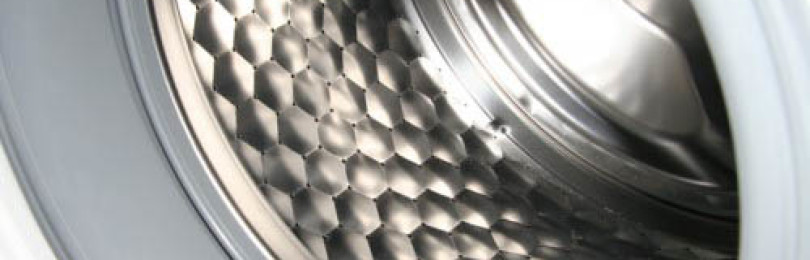

Manufacturers of washing machines are constantly trying to replenish the market with new, more advanced models. Not so long ago, washing machines with a honeycomb drum appeared. According to the creators, the surface of these elements is significantly different from the usual versions, allowing you to avoid problems associated with premature wear of materials during washing. What does a honeycomb drum look like in a washing machine?

Manufacturers of washing machines are constantly trying to replenish the market with new, more advanced models. Not so long ago, washing machines with a honeycomb drum appeared. According to the creators, the surface of these elements is significantly different from the usual versions, allowing you to avoid problems associated with premature wear of materials during washing. What does a honeycomb drum look like in a washing machine?

Familiar version

Such an element is made of a metal or plastic cylinder with holes. If things are loaded horizontally, then this drum has a wall, and in the vertical version, there is a bottom.

The holes made throughout the drum are necessary for the circulation of water that is supplied to the tank. Their number and size are determined by several parameters:

- high-speed rotation mode;

- water pressure, etc.

Such holes are necessary, but they are the ones that pose a danger to tissues.

Linen rubs against the drum walls

Fabric is a special weave of threads consisting of individual fibers. The strength parameters of the fabric will depend on the strength of the latter and the density of the weave. For example, a material made from polymer threads resists friction well when compared with fiber of natural origin.

Load the laundry and turn on the washing machine.The fabric experiences friction against the drum walls and is washed with water jets carrying particles of washing powders. Thin woven fibers, as if on the surface of a grater, rub against metal walls with holes. Their edges are not sharpened, but they are still capable of imparting a certain degree of sensitivity to the process. After such washing, the material begins to gradually wear out. After a certain number of similar procedures, no trace remains of the previous strength. This applies most of all to wool products, cotton items and other delicate materials.

And if at least one thread is knocked out in some thing, then everything is much worse. An unsuccessful cling to a hole in the wall of the drum is enough, and the thread will be pulled out, which will lead to the destruction of the fabric.

What is a honeycomb drum?

In such an element the danger to things is much less pronounced. This technology was developed and installed for the first time on a laundry unit from Miele. Manufacturers explain that nature pushed them to the invention, and when creating a new drum, they were guided by the result of the work of bees - honeycomb holes.

Experts assure that all such words are considered fiction and a common marketing technique. All that unites the drum with the bees is the inner walls, made in the form of a honeycomb, in the corners of which there are small holes for supplying water. However, there are undoubtedly advantages over a simple drum.

Washing in the new drum is much more gentle, the fabric receives less damage, and spinning occurs in a delicate mode. Clothes hardly fit into the holes.

Even a simple naked eye will be enough to determine that the fabric remains smoother after washing.

It should be said that the new drum model is durable and durable. The cast structure is produced by rolling and has no welds, which allows for an extended service life.

The company's experts testing their invention were able to experimentally prove that the cellular model is much more economical than a conventional drum and uses water and electrical energy sparingly.

Note that the holes for water in the new drum are much smaller, and accordingly, their area will also be smaller. The water stays in the drum a little longer, cleaning things more effectively. The likelihood of small foreign objects getting behind the drum circuits has disappeared almost one hundred percent. And this already creates protection for the remaining units of the machine from mechanical damage.

To make the water move much more intensely, there are water intakes. The smooth surface of the walls, as the main factor in the safety of the material, is constantly under close control. Small doubts - the item will be sent for revision or will be rejected.

The presence of honeycombs allows you to create a film of water that softens the friction of things and improves their washing. It is thanks to the honeycomb that the area of contact between the drum walls and materials has been reduced, which also has a positive effect on the friction process.

Are there any disadvantages?

There is only one – the cost of the product. The technology is new, and it will cost, quite naturally, somewhat more. Some consumers recognize the complete superiority of the new drum model, but are not yet in a hurry to overpay significant amounts for washing machines.

Does such a choice make sense?

Although the price is high, for the money paid you get quality and economy of the washing process. And today no other washing machine can provide this. A tank that looks like a honeycomb will better clean things from dirt without rubbing or deforming them.

Conclusion

The improved drum of a washing machine has significant advantages over the designs we are used to. This is already quite obvious even during the toughest spin cycles, when clothes are not pulled into the holes and little effort is required to remove them from the drum.

For this reason, various clothes and other items that were previously always washed by hand, so as not to cause damage to delicate materials, will never be damaged in a washing machine with such an updated drum.

The new invention is a metal cylinder on which convex hexagons are stamped.