The washing machine requires disconnecting from the water supply, and it is advisable to do this whenever it is not in use. This is primarily due to the fact that in systems that supply water, pressure surges occur; as a result, water hammer can cause damage to the hose or valve, which will lead to the need for its repair or replacement. In addition, there is a risk of flooding your own apartment and the homes of your neighbors.

You can ensure that the pipe that supplies cold water is shut off using a washing machine faucet or valve. Of course, this may be the first item you come across, but it is best to use equipment that is functional, stylish, and easy to use.

Purpose of the faucet for the washing machine

The fact that a tap is required while using the washing machine and that it should be turned off during inactivity is indicated in the instructions for use.Two main reasons can be considered as an explanation:

- First, the hose, which is flexible, is not designed to hold constant pressure in this system. If it increases, the shell may break through in the event of sudden jumps.

- Secondly, the shut-off valve (aka check valve) in the water supply system is characterized by a design consisting of a spring and a rubber disk, which, in turn, is designed for temporary operation if the chamber with the drum is filled with water. Due to constant pressure, the spring stretches, and the gasket may burst. All this, one way or another, leads to disruption of the functioning of household appliances and leaks.

It's also worth noting that the lack of a tap in this entire system has other dangers. For example, they are that breakthroughs are most often discovered at night, which leads to an increase in the amount of damage.

In any case, the faucet must function according to the “on-off” principle; regulation of the water flow is not necessary. Therefore, it is most advisable to use designs with low cost and increased reliability. The choice of body shape is made depending on the ease of connecting access to the handle.

The principle of operation and design of the faucet for the washing machine

Today, there are quite a large number of designs that feature a ball valve designed to run SMA. However, they rely on the action of a locking system that is based on the ball principle.

The essence of the unit’s operation is that the shut-off element is nothing more than a ball equipped with a large through-type hole.In the process of turning the handle, it rotates. When turned to the “Open” position, the axis coincides with the direction of the water flow. If it is turned to the closed position, the ball rotates and the flow of liquid is blocked. The angle of rotation of the handle is insignificant and amounts to 90 degrees.

The design of the ball valve is as simple as possible, however, it is characterized by an increased degree of water resistance and small dimensions, as well as ease of use. Here are the basic components of this design:

- body part (a collapsible element made of brass - chrome/nickel plated, the pipe has a thread that is needed for connection to plumbing fixtures);

- ball (it is made of ground or polished brass, but there is chrome on top; inside the body part, in turn, there is a rectangular recess into which the rod is inserted);

- rod (this unit is a rod made of brass, there are rubber rings on its body, and there is a tap at one of the ends, there is a hole on top for screwing in the screw nut, there is a thread on the pulley);

- seat and sealing type rings (they are saddle type and are placed on both sides of the ball, respectively, in the inlet and outlet areas, due to them, increased tightness is ensured, and they also create obstacles to the flow of water into the pipe in the case of a closed position);

- handle (it is rotary and in design resembles a lever, a butterfly, it is attached to the rod using a special nut or screw made of steel, the handle itself is made of steel or aluminum, polymers are used as a coating).

Types of taps

Today, there are several types of faucets for washing machines on the market.

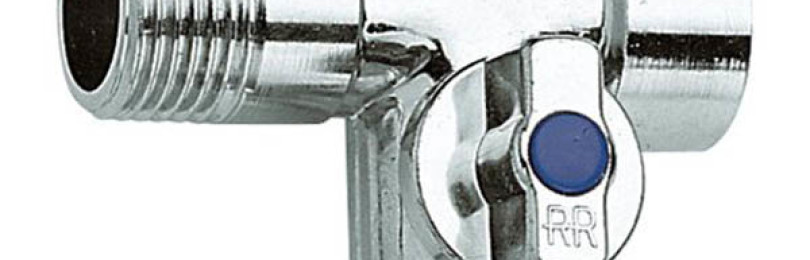

Angle tap

This mechanism is simple and features an L-shape, which makes it possible to change the direction of the pipe in the room. The model is ideal for connecting close to a wall, as well as in a corner, so it can be used near a sink or when running the supply pipe upward from under the floor.

Straight-through ball valve

Inside it is a metal ball with a hole in it. The specific element is located in a round shaped seat equipped with passage channels located on opposite sides of the walls.

Due to the rotation of the ball with its holes towards the channels, free passage of liquid occurs. If you change the position to a right angle, the passage will be blocked 100%, this will happen due to the blank walls of the sphere, which are able to withstand impressive pressure. The cases are made of duralumin, brass, silumin.

The device itself consists of a body part, a handle, a bolt mechanism, a nut, rings (saddles), stuffing box bushings, and a rod. The design also includes sealing rings and support washers.

The advantages of this type of design are the high level of strength of the internal mechanism and the ability to withstand high pressure.If we talk about the disadvantages, they are the impossibility of repair and the need for sufficient space for installation and use of the product.

This type of tap usually does not require replacement of gaskets, and the water shuts off quickly. In this regard, they are especially popular.

Three way valve

An alternative name for this element is a tee. It operates simultaneously on three sides and is equipped with two separate lines located inside. When one tap opens, the second one closes automatically, and the reverse sequence also applies. This option is optimal for activating several devices at the same time, for example, a machine and a drain tank.

What type of crane should you choose?

In fact, there are several selection criteria. They should definitely be taken into account:

- To instantly turn on and stop the water supply process, ball-type products are used. In them, the locking mechanism ensures that the flow of water is instantly blocked when the handle is turned 90 degrees.

- To ensure a presentable appearance, as well as to prevent unplanned turning of the handle, it is worth using products equipped with a rotary lever, which are compact in size and butterfly shaped. In places where access is difficult, it is advisable to use models with asymmetrical levers that turn quite easily and simply.

- Brass is an ideal material for the production of shut-off valves. The fact is that it is not subject to corrosion processes and can serve for decades.It is usually accompanied by a chrome plating, which, in turn, gives it a presentable appearance. The taps are installed in a pipeline made of metal or polymer.

- The choice of a specific design depends on the connection method. If the installation is carried out in a gap or pipeline to which sinks, faucets, and hoses are connected, it is customary to use a triple design. If the water socket comes out of the wall, it is logical to use a corner type housing, because direct modification is inappropriate in this case.

- The position of the handle also plays an important role, in which the valve takes the open or closed position. It is advisable that the valve, which is located close to the wall covering, opens at an angle of 90 degrees to the plane and protrudes slightly outward. This approach will prevent unwanted rotation and opening of the mechanism.

- When choosing the optimal model on the market or in a store, it is worth taking into account the manufacturer and its reputation, experience, and reviews. The manufacturer's logo is applied to the body part. Brands such as Elsen, Grohe, Bosch, Bugatti, etc. have proven themselves well.

These are the main criteria for choosing a faucet, which you must pay attention to so as not to lose money.

What materials are taps made from?

In general, there are two main materials that are used in the faucet manufacturing process. Of course, there are many more options, but these are the products most often found in stores:

- Silumin. This is an alloy containing aluminum and silicon. The key advantage of this type of raw material is its relatively low cost. This is where the pros end and the cons begin.This is primarily due to the fact that the models are very fragile and are not able to serve for a long time. Since there is no point in saving on taps, it is better to immediately choose something more reliable and durable, otherwise, as they say, “the miser pays twice.”

- Brass. This material is durable and resistant to moisture. Besides, it looks quite beautiful. The only drawback is the relatively high cost, but it is fully justified by the set of optimal consumer characteristics.

Thus, a brass faucet will serve for a long time and without complaints, while a product made of silumin can become unusable quite quickly.

Crane service life

The durability of such installations is determined primarily by the material from which they are made. Of course, the degree of intensity of their exploitation plays an important role. For example, under conditions of stable pressure in the network, if it does not exceed 30 atm, the temperature value of the water is no more than 150 degrees, the period of operation can be 15-20 years. In this case, the absence of regular impacts and intensive use of the machine plays an important role.

If the valve constantly opens and closes, for example, several times a day, and a large number of emergency situations are observed on the pipeline, the service life will be reduced by approximately 2 times and will be 7-10 years. Plastic models equipped with a polypropylene body and a brass ball can last for half a century or even more. However, to achieve this result, the operating pressure must be up to 25 bar, and the temperature mark of the carrier must be up to 90 degrees.

Self-selecting faucet

In the process of independently selecting a unit, you should pay attention to the following points:

- Crane type. This is the first thing to consider. If the machine will be installed in a kitchen or bathroom with limited space, where it is meant to be placed close to the wall, you should pay attention to the corner type model. In this case, the water pipe will remain in the wall, only the node intended for connection will be outside. If you will be connecting other household appliances together with the washing machine, it is worth purchasing a tee.

- The second factor is the material of production. You need to take into account the fact that budget samples do not last long, so you should not save on this point. It is more logical and expedient to purchase a faucet made of brass. Plastic models, of course, are also good, but they are characterized by some limitations in terms of temperature and operating pressure.

- Correspondence between the threads of the pipes and the tap itself. Today you can find different connection options on sale, so choosing exactly what you need is quite easy.

- Character of the valve. When installing a crane in a space that is limited, or when it is in plain sight, you should pay attention to the “butterfly” model. It is characterized by its small size and has a presentable appearance. As for installing equipment in hard-to-reach places, in this case it is worth giving preference to the lever, because in the event of an emergency, this valve will be grabbed and closed much easier and faster.

The manufacturing company also plays a role.It is advisable to choose units from well-known brands and not to buy too cheap faucets from dubious manufacturers. Such purchases will not be destructive to the budget, because... They are inexpensive and will last for a long time.

Preparing tools and materials for connecting the tap

Before proceeding directly to installing the shut-off valve and connecting the machine, it is necessary to take into account a number of factors. In particular, to answer the question: is there a correspondence between the quality of tap water and the rational operation of equipment? If the water is bad, you should buy a filter; in the long term, this step can become very significant. It will be installed directly in front of the tap.

The second point that must be taken into account is whether the supply hose will be sufficient for the washing machine to reach the place where it will be connected. If the answer is no, you should get a longer hose. Increasing the length in this case is unacceptable, because in this case there is a high risk of leaks. The hose, which is specialized, is equipped with a filter device and contains such important elements as a coupling and a ring.

To carry out self-installation or replacement of the faucet, you will need a screwdriver, a wrench or adjustable wrench, flax fiber or specialized tape, and a hose. Moreover, the last unit must be purchased separately, because it may not be included. The length reserve should be 10%.

Faucet installation and connection

Below we will consider the procedure for carrying out installation activities in relation to the crane, depending on the location of its installation:

- In the case of using a wall-type water socket, straight or corner elements are used. To carry out self-installation or replacement of the faucet, you will need a screwdriver, wrench or adjustable type, flax fiber or specialized tape, as well as a filling hose. Moreover, the last unit must be purchased separately, because it may not be included. The length reserve should be 10%. In most situations, it is equipped with an internal thread into which the fitting is screwed; it is also important to remember about winding up tow or FUM tape. To make the connection look aesthetically pleasing, a decorative disc is used.

- When installed on a flexible pipeline, which is most widely used, a tee valve is used. The water needs to be turned off, the hose must be unscrewed, and then the tap must be screwed onto a water-type pipe. A hose nut is screwed onto the outlet located on the other side, which is directed to the mixer. A hose is screwed to the side element. A threaded connection is not required for this. With this approach, the installation process becomes as simple and fast as possible.

- In the case of tapping into a pipe, the machine is usually located on the side opposite the sink, and it is impossible to mount the hose at the branch point. In this case, a tee is soldered into a polymer pipe (if it is made of steel, it cuts in); for this, expensive transition materials and couplings are used. At the very beginning, a section of pipe is cut out; it should be the sum of the lengths of the filter element and the tap. To cut metal pipes, it is customary to use a grinder; for plastic, scissors are used. After this the carving is done.

If the faucet being installed is made of plastic material, it must be adjusted to the dimensions of the pipe; to solve this problem, it is customary to use a calibrator. After this, the metal connections are tightened using an adjustable wrench and sealed with FUM tape and tow.

Products made of plastic material, in turn, are fixed with tightening rings. After this, the outlet is connected to the hose.

Carrying out these activities without having plumbing skills will be problematic. Therefore, you will have to involve a master in the work process.

- Installation in a mixer involves the use of a “triple” tap, which is usually mounted in the area located between the body part and the flexible hose. At the first stage, the diametrical cross-section of threaded connections is measured, only after this can you begin to select a valve.

The main disadvantage with this type of arrangement is the lack of any aesthetics. This is primarily due to the lack of symmetry and balance between the individual elements of the mixer. To install a faucet using this method, unscrew the gander or hose and only then screw on the tee.

If you do the work yourself, it is worth remembering that if the kit does not include an inlet hose, you should give preference to a double model with wire reinforcement. Such samples ideally withstand pressure within the network, and also guarantee no interruptions in the power supply during washing. An important role is played by the purchase of filtering devices (for running water), which are installed on taps in the area of their connection with a water pipe.

End valve installation

Connecting to a tap that is already ready for use is quite simple. All that is required for this is an adjustable wrench and a FUM tape. The procedure looks like this:

- first, the external thread in the area of the pipe or tap is wrapped with tape to ensure that it is screwed on with force;

- a valve is screwed to the pipe, first all this is done manually, then using a key;

- the inlet hose is connected, and then the plastic coupling is screwed along the thread to the very end;

- the valve opens, after which it is necessary to check the connections for leaks.

The hose itself can have different configurations, in particular, angular or straight. In the first case, the angled end is screwed to the SMA, which facilitates its closer installation to the wall. In the second situation, the connection is made to the shut-off fitting.

Installation of a walk-through valve

There are several options for installing an outlet on your washing machine yourself without cutting the pipe:

- Installation of a straight-through tap into the outlet of the boiler. You can also use a dishwasher or other object for these purposes. The tee is installed in front of the tap, resulting in a structure consisting of two devices located next to each other.

- You can also connect the washing machine in front of the faucet on the sink. All you need to do is disconnect the hose from the cold water supply and then install a washing machine pass-through faucet into the pipe area. Next, a mixer will be connected to it, and the hose itself will be connected to the outlet of the tee.

- The machine switches to a drain type tank; in fact, the technology is similar to that in the case of connecting the system to a mixer.

The process of installing a walk-through faucet is almost no different from the usual one. All connections are sealed using winding.

Errors when connecting the tap

In the process of connecting a faucet, beginners traditionally make several common mistakes. To avoid them when working on installing a crane yourself, you need to follow the recommendations of experts and take into account the principles of installation work:

- It is not recommended to overtighten the nuts, because in this case there is a risk of stripping the threads and causing a leak.

- The use of compaction materials during the work process plays an important role. It can be linen thread or FUM tape.

- During the installation process, the clips cannot be further than 10 cm, otherwise if the element is rotated, the pipe will move, which will definitely have a bad effect on the final quality of the connection.

- You also need to ensure that the arrow that was stamped on the fitting completely coincides with the direction in which the water flow is moving.

- In the process of cutting out a section of pipe and installing it, the ends must be thoroughly cleaned so that there are no burrs in them. Otherwise, they will gradually begin to separate under the influence of moisture, and the pipes will become clogged.

- It is strictly not recommended to connect the machine to the heating system. This is primarily due to the fact that the water present in radiators has a technical purpose and cannot be used in the process of washing things.

By following these recommendations, you can install the faucet as efficiently as possible.

Conclusion

Thus, the faucet for a washing machine is the most important unit, since without it the process of high-quality washing is impossible. With a competent approach to its selection, installation and operation, the product will last for a long time and work as efficiently as possible.