Nowadays buy a washing machine Simply, household appliance stores offer models for every taste and budget. This is true, but there are situations in which buying a new device is impossible or irrational. In this case, a homemade washing machine will come to the rescue. There are several popular designs, each of which is easy to repeat.

Nowadays buy a washing machine Simply, household appliance stores offer models for every taste and budget. This is true, but there are situations in which buying a new device is impossible or irrational. In this case, a homemade washing machine will come to the rescue. There are several popular designs, each of which is easy to repeat.

When do you need something like this?

To some, the phrase “homemade washing machine” will seem absurd, but in reality such a solution can be very useful. For example, this is a great thing for a summer house. It’s hardly worth buying a new washing mashine, knowing that for most of the year it will just sit in an empty house.

Another situation - automatic washing machine failed and was taken to the workshop. The breakdown is serious, repairs are delayed, hand washing is not an option - you can spend a few hours and assemble a simple device with your own hands. Among other things, a homemade washing mashine will be a good solution for young families forced to huddle in rented apartments.

Full-fledged washing machine from scrap parts

Of course, make your own automatic device with multiple washing programs It won’t be possible at home, however, if you have more or less straight hands, it’s not difficult to assemble a simple machine with an activator.

Preparing for work

The first step is to select parts for your future homemade washing machine. You will need:

- laundry tank;

- electric motor;

- sheet of plastic or textolite;

- shaft for transmitting rotation;

- connecting and threaded bushings;

- shaft casing;

- activator.

In addition, you need a sheet of rubber for making gaskets (an old tube will do), rubber plugs or bushings of small diameter, they will serve as limiters and will hold the lid on the tank during washing.

Assembling a homemade washing machine

The most important part of the homemade product is the tank; as such, you can use a large enamel or aluminum pan; no changes will be made to its design, so at any time it can be used for its intended purpose. If you don’t have a large saucepan, a homemade machine can be made from a barrel of a suitable size.

The tank is ready, time to work on the erasing part (the cover with the motor, drive and activator installed on it). It will require a base. A disk made from any sheet material available on the farm is suitable as such. It is better to take plastic or textolite, but you can get by with multi-layer plywood. When using wood, it is important to provide it with reliable protection from moisture.The diameter of the disk should be 10-15 cm larger than the diameter of the tank.

A hole for the shaft is drilled in the center of the disk; when using soft material, a sleeve should be pressed into it. It is recommended to use the unit from the “Skillful Hands” machine as an engine; the advantage of such a solution is that the engine does not need to be remade. If you use another unit, you will have to solve the issues of connecting the activator shaft; adapter bushings of different sizes will be required.

The motor is secured using the supplied bolts, washers and bushings; it is advisable to put a rubber gasket between it and the base; it will protect against splashes, reduce vibration, and reduce noise.

The rotating shaft must be closed, otherwise laundry will wrap around it, which is fraught with consequences. A small aluminum pan will work as a casing. A hole is drilled in its bottom. The activator sleeve is installed into it and secured from the inside with a nut. Since water will still get inside the “casing”, there is no need to use sealing collars.

The pan is attached to the disk from its lower side using self-tapping screws or bolts with nuts. The role of fastening corners will be performed by handles.As a result of all these manipulations, the following design will be obtained: a disk, a motor is installed on top of it, its shaft passes through the base and “casing” and is connected to the activator.

The homemade washing machine is almost ready, you just need to connect the motor to the mains and take care of safety. For power, use a regular cable with a plug for household appliances; be sure to insulate the terminals using electrical tape or heat-shrink tubing. In addition, the engine must be closed. A cap from an old vacuum cleaner will do. To prevent the lid from “moving” during washing, move around the circumference from its lower part shock absorbers are attached, plugs or rubber bushings will do.

You can start washing. Throw laundry into the tank, add water, add powder or liquid laundry soap. Close the lid and plug in the device.

Elementary design of an aquarium compressor

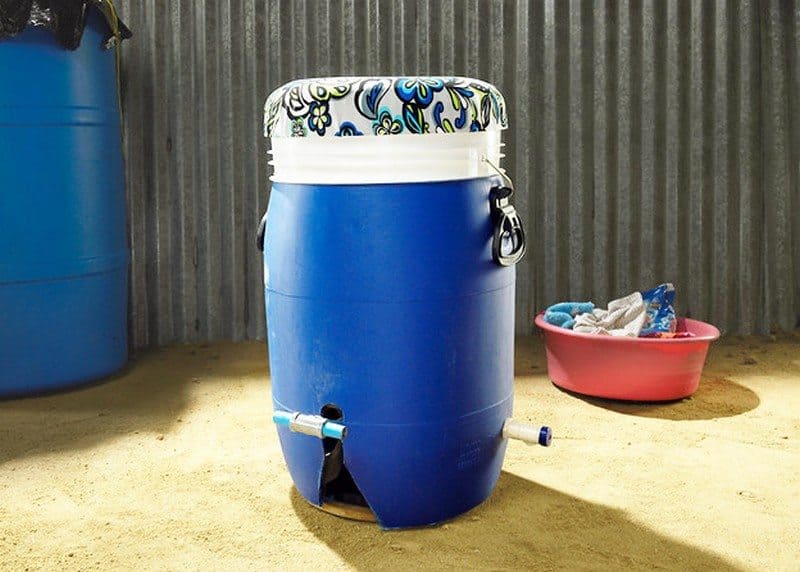

For small washing volumes, you can make a simple homemade washing machine from a bucket and a regular compressor. The role of the activator in it is performed by a stream of small bubbles that rise from the sprayer. The air pressure helps to mix the water, “knocks out” dirt, cleaning clothes. Of course, you shouldn’t expect high performance from such a design, however, it will quickly refresh your laundry and remove simple stains.

In principle, the manufacturing process of this mechanism is limited only to selecting a suitable container for the tank and installing a sprayer inside it.

Homemade manual washing machine from a bucket and plunger

The rubber part of the plunger needs some modification. Windows are cut out in it (from 3 to 6). The handle is inserted into the hole in the lid, water is poured into the bucket, laundry is placed and detergent is added. The device is easy to use - you just need to raise and lower the plunger handle, mixing the contents of the tank.

Good to have on hand automatic washing machine, but sometimes it’s not there, which means you need to use your ingenuity. With a little effort, a few hours of work, washing will become a simple and enjoyable task again.