In most cases, people turn to a repairman when their household appliances break down. But often the breakdowns are simple and you can deal with them yourself. You can also handle the repair of washing machine shock absorbers on your own. Their dismantling and installation does not require much effort and professional skills. Even a beginner can quickly and effectively restore the functionality of a washing machine if he follows the instructions.

The difference between shock absorbers and dampers

The main difference between shock absorbers and dampers is the presence of springs in the former and the absence of springs in the latter. Rather, dampers are advanced shock absorbers, so the springs are not installed inside them, but on top to support the tank. This makes it easier and faster to change springs in case of failure.

Without these devices, washing machines would not last long. Under high loads with the application of rotating force, units, contacting parts and connections would quickly fail. But depending on the settings, washing mode, brand of unit and functions performed, the drum performs from 700 to 1800 revolutions per minute.

Shock absorbers for washing machines are similar in principle to washing mashine shock absorbers and perform the same role.

Typical causes of shock absorber malfunctions

Reasons for device failure:

- Natural wear and tear. Loads inevitably lead to wear of elements.

- Marriage. Any part may be of poor quality, and this will accelerate wear.

- The machine was not properly balanced during installation or use. The load is distributed unevenly and wear occurs faster.

- Constant overload of the tank. Excessive vibrations will shorten the service life.

- Washing clothes that cannot be washed at home. To remove dirt from some items, the power of a conventional unit is not enough, so they need to be washed only in machines that are designed for high loads. They are used in laundries and dry cleaners.

- Sudden braking of the drum due to a sudden power outage during spinning. This can completely break an already fragile part.

- Drying of the lubricant. Without it, it is impossible to maintain the level of friction necessary for normal operation.

In order to avoid damage, it is important:

- Install the washing machine on a flat and hard surface so that it does not move to the side and the tank does not hit the walls of the case, damaging other parts. You cannot place it on a wooden floor because it will sag too much. The surface should also not be slippery. You can place a rubber mat under the washing mashine to provide good grip. The mat can be replaced with rubber feet.

- You shouldn't ignore the legs of your washing machine altogether. It is important to check their integrity, and if something is wrong, replace them.Modern design makes this easy to do, since they can be easily unscrewed. After replacement, it is better to strengthen them with locknuts to avoid further damage.

- Do not overload equipment with laundry.

- Place laundry in the drum correctly and evenly.

- Check items for dangerous accessories, and always remove small change from pockets before washing.

How do spring shock absorbers work?

Shock absorbers are devices that dampen vibrations that occur during washing. They were used before, but now dampers that have a less complex design are installed in washing machines. They perform the same role as shock absorbers.

They perform the same role as shock absorbers.

Shock absorbers consist of:

- The housing is in the form of a cylinder, inside which the remaining parts are located.

- Pistons with rods. These are moving parts. The piston is perforated so that the air inside the cylinder can easily escape and does not create unnecessary resistance.

- Polymer liners on which the rod is attached to the drum.

- Return spring. It makes the piston move.

- Gaskets. Fixed at the base of the rod. It is needed in order to reduce friction during movement, and also ensures tightness.

- Long-drying lubricant. The piston and gasket are impregnated with it. It is needed in order to increase friction between the piston rod and the inner walls of the cylinder.

The work process looks like this:

- When sharp surges begin during washing, the rod begins to move.

- He pushes the piston, and it begins to move inside the cylinder, pressing on the spring. Due to its resistance, the mechanism works.

- Thanks to lubrication, movements are targeted and produce the desired effect.

- After the vibration intensity decreases, the rod returns to its original position. And so on in a circle.

There are shock absorbers that are located vertically or at an angle. The shock absorber is not a universal part, so it looks different in each specific machine.

A shock absorber of a certain type is designed to work with a certain mass of laundry that will be washed.

The shock absorbers of a standard machine for home use absorb vibrations from 40 to 180 N. For units for dry cleaning and laundries, this figure is much higher.

Shock absorbers also vary in size and hole size for installation.

Damper device

Dampers are either collapsible or non-dismountable. In the first case, you can replace the compressed liner, and in the second, if it breaks, the entire device is replaced. The dampers are located below, under the washing machine tank. And the tank itself hangs on springs.

Damper device:

- Cylindrical body.

- The piston that is inside it.

- A gasket that is attached to the piston. Creates additional friction.

- Rubber bushings that connect the damper to the tank. They are also called pressed liners. They also help dampen vibrations. Friction occurs between the liners, rod and piston. The bushings are pressed to the rod with steel brackets. They have a U-shape. Their lower part is connected to the body of the washing machine through a rubber gasket. The upper part is clamped with bushings.

Principle of operation:

- When the gasket rubs, it creates resistance.

- Resistance dampens the resulting vibrations.

How to check the performance of shock absorbers and dampers

Despite the fact that each washing machine model is unique, and there are always differences in design, the general structure of the units is still similar. And the repair methods are the same.

Problems with shock absorbers are indicated by:

- Tightly rotating drum.

- When it stops, you can hear a dull thud.

- Strong knocking and noise during operation.

- The engine drive belt regularly becomes loose and falls off.

- The vibrations and vibrations are so strong that the machine moves and changes position while washing.

The machine may vibrate strongly if the laundry has not been loaded into the drum correctly, i.e. in a large lump. Nowadays they make washing machines that stop in this case and continue working only after the clothes have been stacked correctly. Most machines continue washing despite problems. If the machine bounces a lot, you need to turn it off and spread the laundry evenly inside the drum. After this, you can start the wash again. To avoid problems, it is best to wash your clothes in small batches.

If there are no knocks, then you can manually check the safety of the shock absorbers. To do this you need:

- Unplug the machine.

- Turn off the water.

- Using a screwdriver, unscrew the unit cover and remove it.

- It is easy to press the top edge of the tank with your hands and then remove them.

- If the tank freezes quickly after pressing, everything is normal. If it starts to sway and takes a long time to come into balance, you need to change the parts.

Signs indicating problems with dampers are exactly the same as for shock absorbers. But diagnosis can be done a little differently.

Procedure:

- First disconnect the unit from the network and turn off the water in the pipe to which it is connected.

- On the back surface of the machine, unscrew the bolts securing the cover.

- Take it off.

- Remove the powder tray.

- Remove the panel covering the drain filter.

- Also remove the control panel by unscrewing the bolts and disconnecting the wires.

- Remove the fastening clamp, followed by the façade cuff.

- Put it in the drum.

- Detach the façade.

- Compress the damper. If it shrinks easily and expands just as easily, it needs to be replaced. If it is difficult to squeeze it, then it is fine and ready to serve further.

Diagnostics of the operation of shock absorbers and dampers can be carried out differently depending on the type of load.

Inspection procedure for vertical loading:

- Press the top of the tank with your hand. If no resistance is felt and the tank pumps when the hand is removed, this means a repair is needed.

- Watch the drum rotate. If it squeaks or is difficult to turn, this indicates a lack of lubrication.

- Disassemble the washing mashine, remove the rear cover. Press down on the tank, lower it down firmly and release it sharply. If the tank jumped and froze, then everything is normal and no repairs are needed.

When front loading, the inspection procedure is different:

- Press on the tank and look at the cuff sealing the hatch. The presence of folds indicates that repairs are needed.

- Pay attention to how far the tank goes down.

The normal condition of the machine is the absence of folds on the cuff and a stable tank that does not sag due to load.

In order to check the serviceability of the shock absorber, one of the ends of its fastening must be disconnected and checked. A damaged shock absorber has a light stroke, which causes powerful vibrations.

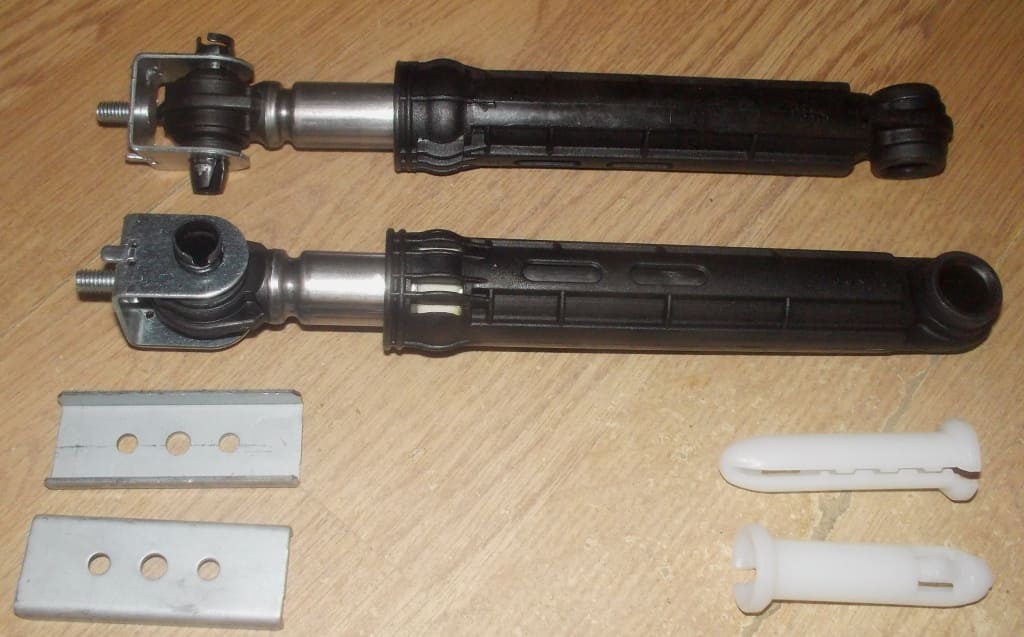

Shock absorbers are fixed using two types of fastening:

- Plastic latches.

- Bolts.

To remove the devices, you need to either tighten the bolts or press in the latches and remove the plastic bushings.

Dampers do not have their own stroke. It is provided by a movable tube or a plate connected to the tank.

Signs of shock absorber failure are visible damage and deformation.The part can be squeezed without effort, and it will make a creaking sound.

Do-it-yourself replacement and repair of shock absorbers

If the cause of the breakdown is a worn gasket, then it must be removed and a new one put in its place:

- A strip 3 mm thick is cut from a belt that matches the diameter of the cylinder.

- They replace the gasket.

- Lubricate it so you can install the rod later.

- Return the rod to its place.

If the problem is a broken spring, proceed as follows:

- The shock absorber is pulled out of the washing machine. It is removed from the top of the housing or the connecting unit on the tank.

- The spring is pulled to the tank and disconnected using pliers, unhooking the opposite end of the part. You can also remove the fastener with a screwdriver.

- Press the latch into the bottom of the part.

- They disassemble the part.

- Replace the damaged spring with a new one.

In some cases, it is enough to change the lubricant for the shock absorbers to work properly again.

Lubrication should be:

- moisture resistant;

- viscous;

- insensitive to high temperatures;

- neutral.

Regular lubricating oil is best. For example, this:

- Amplifon;

- Anderol.

On the other hand, it is easier and more reliable to replace the entire part completely. Shock absorber fragments wear out at approximately the same rate, so replacing one element will be pointless if another immediately fails.

The production of shock absorbers is not carried out by factories that produce washing machines, but by third-party enterprises.

Parameters that you need to pay attention to when choosing a new shock absorber or damper:

- Stiffness that matches the stiffness of the element that will be changed. It is indicated on the body. It could be 80 or 85 N.

- The bushings must have exactly the same diameter (8, 9, 10 or 11 mm).

- The distance between the mounting axes in the most compressed and fully folded state.

- Mounting type. These are bolts or rings made of plastic.

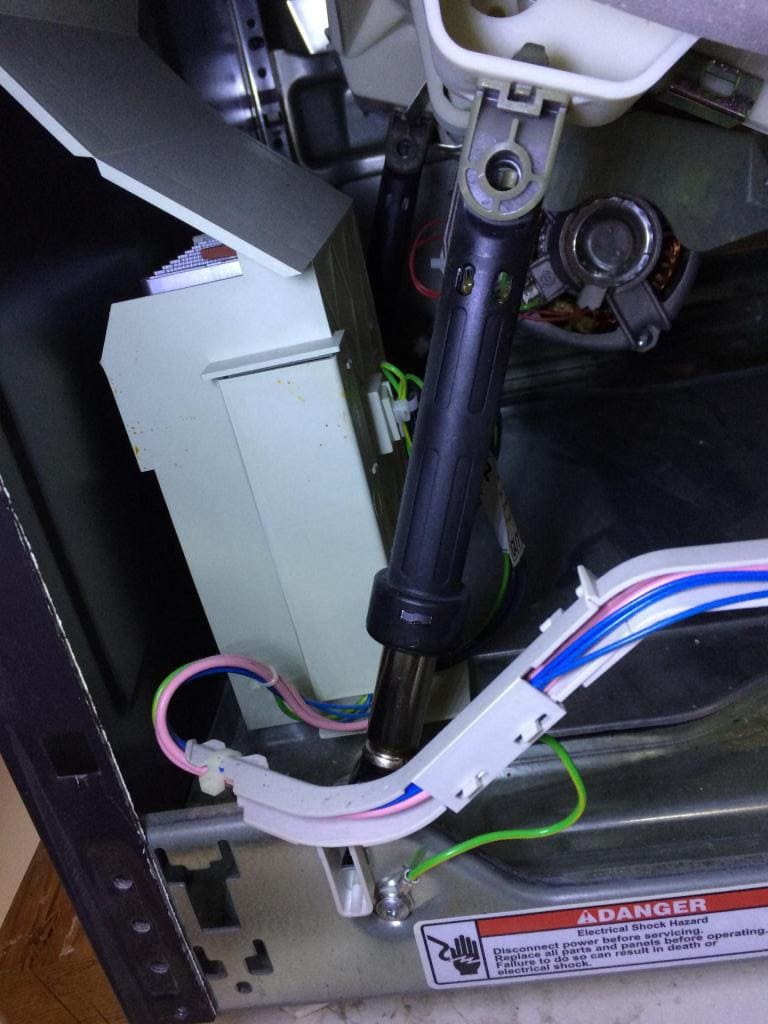

In order to change shock absorbers, you need:

- Remove part of the machine body from the side from which the repair will be carried out.

- Remove broken devices.

- Replace them and put the unit back together.

Do-it-yourself replacement and repair of dampers

Depending on the model, the installation of dampers is slightly different.

Sometimes it is enough to put the washing machine on its side so that you can get to the necessary parts.

Sequencing:

- Disconnect the unit from the power supply and remove the water drain hose.

- Open the door, which is located under the hatch for loading laundry.

- Place a container under the hatch to allow liquid to drain there.

- Unscrew the filter plug by moving it counterclockwise and remove it.

- Wait for the water to drain.

- Turn the machine on its side.

- If there is a bottom, unscrew the fasteners and remove it.

The repair procedure in which the front wall of the washing machine is removed:

- Get rid of the top cover.

- Remove the powder and conditioner tray.

- Remove the control panel by first unscrewing the screws.

- Open the machine door.

- Pull the cuff and remove the clamp.

- Unscrew the screws securing the front wall and remove it.

- Remove the wires.

- Look under the tank. Remove the springs to the body and unfasten the latch.

- All that remains is to replace the damaged fragments of the part or completely change the damper, and then reassemble the unit in the reverse order.

If the problem lies in the liners that hold the dampers, then they need to be replaced. It is also important to compress the brackets so that they become more elastic, putting more pressure on the bushings and increasing the level of friction.

Replacement of liners takes place in this order:

- The bracket mount is unscrewed from the washing machine body, after which the damper is disconnected from the tank.

- The bracket is clamped with a vice so that the rods are pressed more tightly against the rubber inserts.

- New bushings are inserted into the expanded bracket.

- The bracket is installed in the washing mashine in the reverse order.

Sometimes the problem occurs with the springs. One part of the spring is attached to the tank, the other to the machine body. As a result, the tank is held at the top of the unit. The number of turns, length and diameter of springs may vary.

The purpose of the spring is to hold the tub in place and return it to its place when vibrations and shaking occur during washing and spinning.

The spring is usually damaged in the part where it is attached to the body. Often a breakdown occurs precisely while the machine is running.

If one of the springs bursts, the tank drops onto one of the shock absorbers, which cannot dampen vibrations.

A fault is indicated by a wrinkled cuff that has moved the drum to the side. To check for damage, you need to remove the top cover and check the springs.

There are two ways to remove the spring. Removal through the top hook goes like this:

- Remove the top of the machine.

- Fix the tank as high as possible by tucking some hard object under it.

- With one hand, lift the spring, and with the other, take a screwdriver and push it under the spring mount in the place where it connects to the body.

- The screwdriver is lifted and the mount is separated from the machine.

- The upper part of the spring is moved to the side, the screwdriver is lowered and the upper part is released.

- The spring is removed from the lower mount.

If the replacement occurs through the lower hook, then the procedure is as follows:

- The top cover of the unit is removed and set aside.

- The tank is raised as high as possible. To do this, you need to put something solid under it.

- The springs are stretched down and the lower fastening hook is removed with pliers.

- Separate the top mount.

Sometimes machine problems occur due to bearing failure. It also begins to vibrate strongly, causing extraneous noise during washing, rinsing and spinning. If nothing is done, the bearings will continue to fail. The drum will begin to spin idle, and the washing mashine will move to the side. Broken bearings cause further damage to the device.

In order to check the condition of the bearings, you need to rotate the drum. If it rotates freely, then no problems are detected. If rotation is constantly interrupted and occurs with difficulty, then the bearings are damaged. Sometimes damage to this part is indicated by oil leaks or rust on the internal walls of the machine.

In some cases, bearings are destroyed due to the fact that the integrity of the tank seals has been compromised.

Sometimes repairs require removing the drum. This process is less difficult for top-loading and front-loading machines. In the first case, the side wall, wiring and counterweights are dismantled. In the second, the pulley is removed from the back.

How to remove the drum from a top-loading machine to get to the shock absorbers or dampers:

- Unscrew the screws that hold the front and rear walls of the machine. Move the panel on the right back, then remove it.

- Disconnect the wires going to the drum.

- Unscrew the screw that holds the shaft that drives the drum.

- The same is done with the left panel.

- Remove the drum from the machine.

How to remove the drum from a front-loading machine:

- Unplug the power cord and disconnect the hose from the sewer.

- Unscrew the screws on the back wall of the machine and remove it.

- Remove the front wall. To do this, move it towards you and then up.

- Remove the top cover. To do this, unscrew the bolts that hold the filling valve and cover.

- Disconnect the wires.

- Remove the tube that connects the powder and conditioner container to the drum.

- Remove the hatch cuff. Unfasten the clamp securing it.

- Remove the inner part.

- Bend the cuff and pull it out.

- Rinse the cuff in soap and water and wipe the areas where it comes into contact with the drum.

- Unscrew the screws and remove. And then put the lid aside.

- Proceed to dismantle the drum.

- Disconnect from the tank everything that is attached to it, all parts.

- Remove all weights, counterweights, springs, bolts and tubes.

- Unscrew the pulley bolt, remove the pulley, screw the bolt back.

- Pull out the drum, after hitting the shaft that drives it several times.

The plastic linings that cover the plates or tubes extending from the tank can fail. To replace the linings, remove the damper:

- The screws fixing the damper are unscrewed.

- Remove the old covers and put new ones in their place.

Another cause of problems is transportation bolts. They are needed in order to secure the machine parts and not damage them during transportation. First of all, fix the drum.

The machine will vibrate if you forgot to remove the bolts when installing it. Moreover, they will damage all other parts of the washing mashine.

During repairs you must follow the following rules:

- Be sure to drain the water from the filter. If this is not done, it can flood the connectors and other electronic devices of the machine. To remove water, the drain filter is unscrewed from the housing.

- Mechanical impact during repairs can easily damage the heating element. Better to take it off. And if you don’t take it off, be very careful.

- To avoid problems with assembly, it is better to photograph the disassembly of the machine step by step. The photographs will serve as instructions for returning the unit to its original condition.

- You can build an organizer for different fasteners. It should have cells that can be signed. Fasteners will be stored in one place and will not be lost. This will ensure a quick and safe process of assembly, disassembly, diagnostics and repair. It also reduces the amount of time spent searching for the right parts.

- If other problems are discovered when replacing dampers or shock absorbers, do not put them off until later. It's better to resolve them right away.

- The only real difficulty for a beginner is the unknown and the uncertainty that comes with it. As the repair process progresses, the anxiety will gradually subside. It will become an experience thanks to which in the future you will be able to confidently deal with other breakdowns, and not only in the washing machine.

If you remove the damaged element of the machine yourself, you can take only that element to the service center. You will not need to worry about transporting the machine or paying for its disassembly and assembly.

Damper or shock absorber failure is easier to prevent than to fix. On the other hand, if a breakdown does occur, you can deal with it yourself, without resorting to the help of service centers. The main thing is to be careful and follow all instructions exactly.

Hello.

Thanks for the wonderful and informative site!

Please tell me (if you know) whether the rods of the new dampers of the BOSCH MAXX5 washing machine, if they are completely dry, can be lubricated with damper grease PMS250000 (or PMS600000)? And which one is better?

Thank you!

Nikolai Mikhailovich