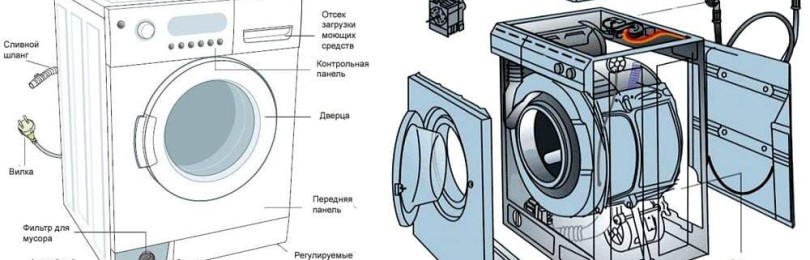

Laundry washing machines, regardless of the manufacturer, have almost the same structure. Individual models may differ in design features such as motor types, loading options, and the presence of additional functions. By imagining the structure of the washing machine, the location of the main components and the operating principle, you can always carry out repairs with your own hands and even prevent various malfunctions. Considering any model from Samsung, Kandy, Lg, Indesit, Bosch or Ariston, let's try to figure out how an automatic washing machine works.

Laundry washing machines, regardless of the manufacturer, have almost the same structure. Individual models may differ in design features such as motor types, loading options, and the presence of additional functions. By imagining the structure of the washing machine, the location of the main components and the operating principle, you can always carry out repairs with your own hands and even prevent various malfunctions. Considering any model from Samsung, Kandy, Lg, Indesit, Bosch or Ariston, let's try to figure out how an automatic washing machine works.

Main components and assemblies

Every washing machine has the same internal structure. To buy a good unit, you should know its structure. So, each machine has:

1. Body part.

Presented with durable metal casing. Designed to prevent damage, scratches and dents, and to keep parts in working order. Consists of a base, side panels, front and rear walls, a lid, a panel with a loading hatch. The front part contains a control panel and a tray for washing powders and rinse aids, which enter the machine using water jets.Front-loading units have a locking device. This washing machine lock securely closes the door during the entire washing process.

2. Water intake system.

After selecting the program, the machine starts and the hatch is locked. First, the valve of the washing machine is activated, through which water enters the drum. The process continues until the sensor receives a command that there is enough liquid in the container to start washing. To ensure uninterrupted flow of water, the inlet hose is connected to the water pipe.

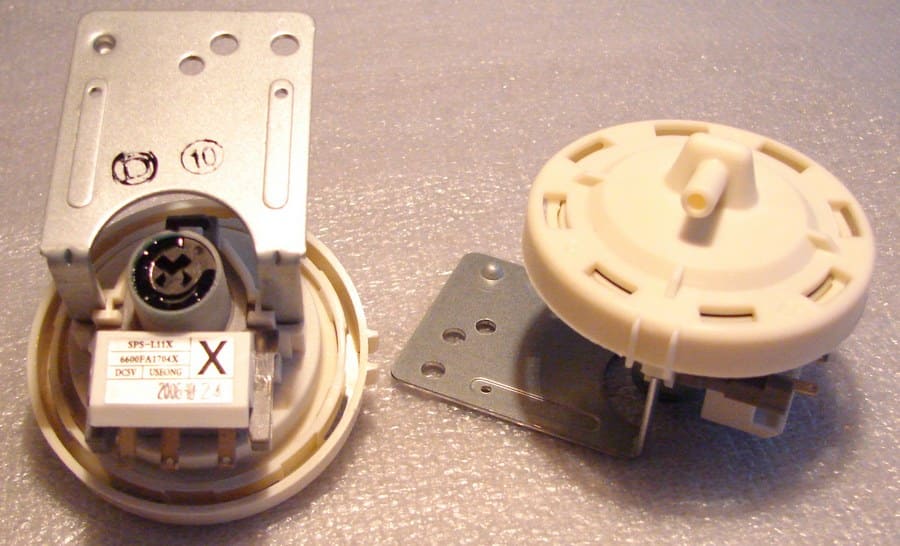

3. Sensors.

These special devices are responsible for the correct and smooth process. Information flows here from every node of the machine. Regulatory devices include:

- pressure switch – controls the water level in the tank;

- air chamber - made of plastic material, located near the drain pipe;

- thermostat – is responsible for the temperature regime of the liquid in the tank. Data from it is transmitted to the management unit;

- tachometer – controls the speed required to perform a spin cycle. Their number is determined by the set washing mode.

Together, all sensors represent the necessary elements that control the process.

4. Tank and drum.

The first element is the most voluminous. Based on its own size, it can hold from three to twelve kilograms of laundry. To avoid vibration during the washing process, the tank and the body are connected in a non-rigid way, for which they use from two to four springs, a weighting agent that eliminates oscillatory movements and vibration, and mufflers located in the lower part of the tank. This set of mechanisms guarantees reliable stability of the unit.The tank has a device with a large number of holes through which water is supplied. As a rule, the tank is made of two parts connected with bolts or clamps, which makes repairs a certain convenience. But in more modern models, such a part began to be made non-separable, and if it fails, a complete replacement will be required.

5. Heater.

Located in the housing, it heats the water. Its power can range from 1,800 to 2,200 watts. It is considered one of the fragile and vulnerable elements of the machine. The performance is affected by scale. To extend the service life, it is recommended to use a plaque remover. How does the heating element work? It heats the water to a given temperature, the process is controlled by a thermostat. It sends a command that heating should be stopped.

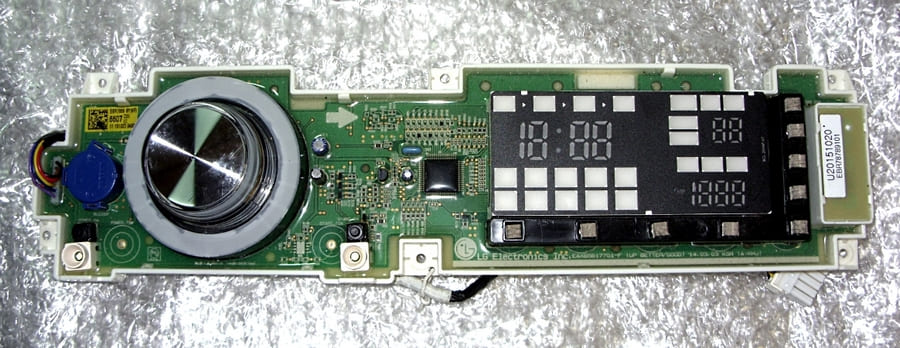

6. Control unit.

One of the important elements controls the microcircuits and is considered the “brain center” of the machine. It is capable of controlling the heating element, tank, drain and supply of liquid, pump and other elements. This unit is quite expensive and helps determine the type of fault, the complexity of the repair work, and the need to invite a specialist.

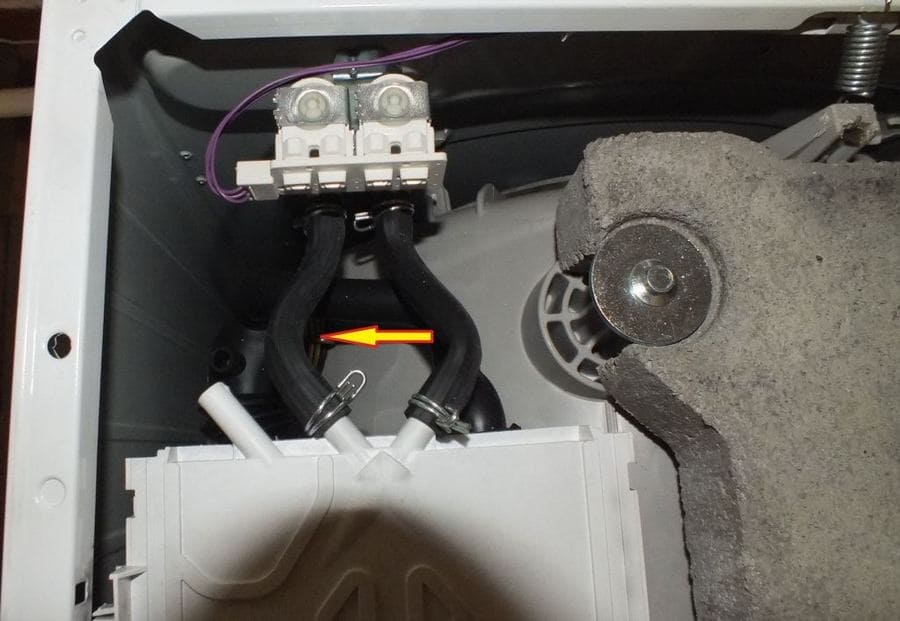

7. Drain system.

When the wash finishes, the machine should drain the dirty water. This is done using a special corrugated hose, the length of which ranges from one to four meters. One end of it is fixed to the pump, the other is connected to the sewer pipe. During the entire operating cycle, water is drained several times. To understand how the drain works, you need to study the internal structure of your machine. This will greatly alleviate possible difficulties with installation or repair.

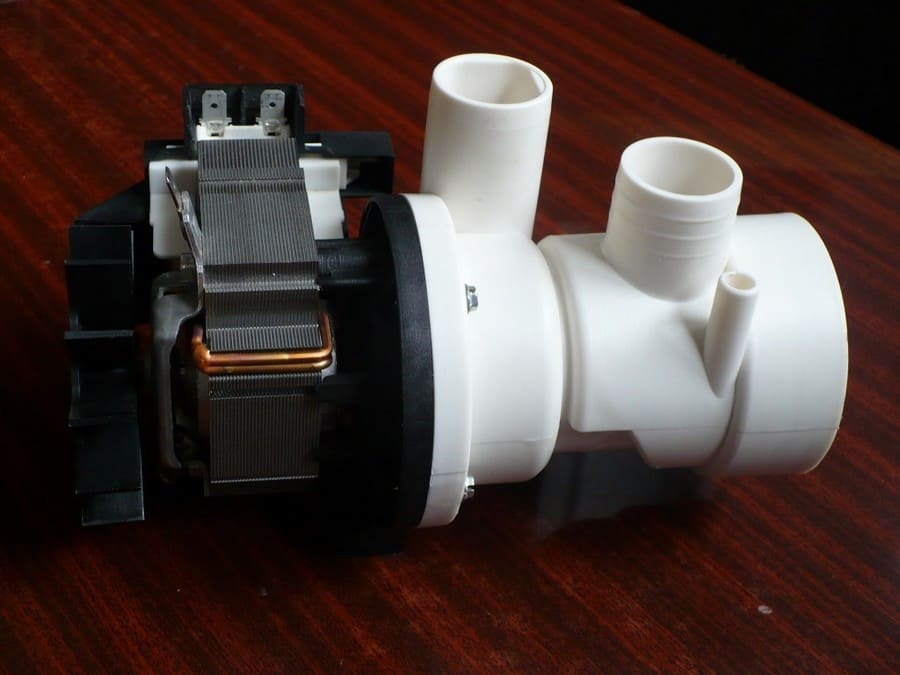

8. Pump.

An important element in the drainage system. The principle of operation is to pump out water while the machine is operating. Structurally, the element consists of an engine with an impeller, a volute and pipes. In household models of washing machines, one of two types is installed - with a synchronous or asynchronous motor. Most of the machines are equipped with the first type; pumps with asynchronous motors are almost never produced.

9. Electric motor.

With its help the drum is driven. Machines are often equipped with commutator-type motors with direct drive. Simply put, the connection is made directly to the drum. This type of motor does not require much energy to rotate, does not make much noise during operation, and practically does not vibrate. Another advantage is compactness.

10. Front type counterweight.

Since the tank must be level during the washing process, this element is installed. It is a block of plastic or concrete. You need to know that vibration gradually destroys the counterweight and wears out the fastenings, since they are also subject to significant loads.

11. Springs and shock-absorbing elements.

With their help, oscillatory movements are dampened. The wear resistance of the system depends on the performance of these parts. If the shock absorbers malfunction, the drive belt will fray, the tank may rupture, and the cuff will fail. The vibrations of the tank are damped due to the fact that all the reciprocating movements of the piston are converted into thermal energy. The installed gasket, impregnated with a special non-drying lubricant, withstands significant friction. If the return spring is in good condition, the piston is able to move in the opposite direction.In fact, the tank simply hangs on springs, the number of which may vary depending on the model of the machine.

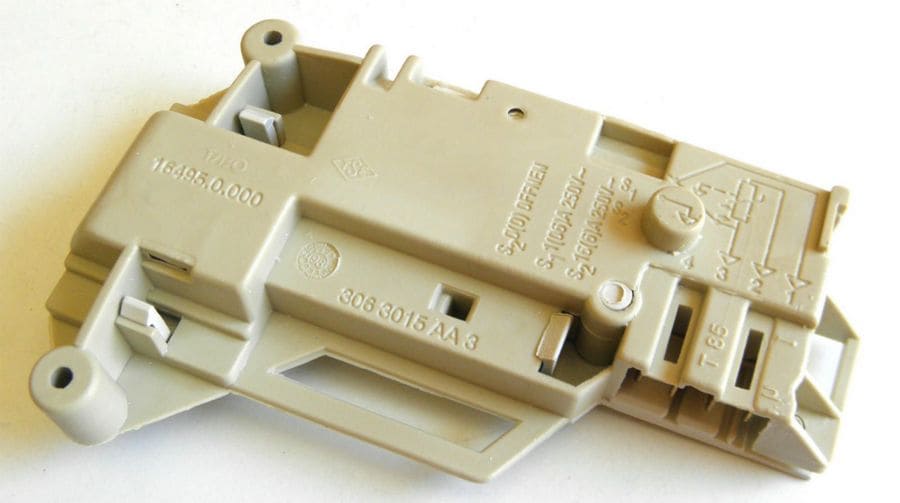

12. Hatch locking device.

The door is located on the front wall, and things are loaded through it. In Ariston machines, the hatch is slightly larger in diameter, which greatly facilitates the process of storing laundry. When the wash starts, a signal is sent to the lock, which securely locks the door.

13. Hoses.

Designed for collecting clean water and draining waste water. The drain can be connected to a special container or connected to a sewer pipe. The filler connects the water pipe to the machine.

14. Pipes.

Made from rubber. There is a filter installed inside that traps powder particles so that they do not clog the drain system. An air chamber is attached to the pipe, ensuring uninterrupted operation of the pressure switch.

15. Drive belt.

Connects the electric motor to the drum and transmits rotational movements. Can be made from nylon, rubber material, neoprene or polyurethane.

16. Additional electronics.

It includes various relays, indicator devices, a display that provides current information, and a navigation panel. Elements intended for control turn on the washing machine, sensor elements and relays monitor the data needed to activate specified modes, LED elements and displays monitor stages and diagnose possible failures. Any element fulfills its purpose, and without it you will not get a normal wash. In addition, the built-in blocking system will not allow the washing machine to start if there is a malfunction.Many models have built-in special indicators that signal the need to contact a service center.

17. Loading hatch cuff.

It is a sealing element made of rubber material that ensures the tightness of the machine. The outer side is fixed to the body, the inner side is fixed with clamps on the tank. Using the cuff, an elastic connection is created between the moving tank and the body of the device.

Working stages

The operating principle is based on the independent execution of specified processes. The machine is entirely under control of their compliance with the commands set by the user. Everything will work smoothly if the laundry washing unit is not damaged. If any problems occur, you can try to fix them yourself or call a technician.

The principle of operation of the washing machine should be considered from the preparatory measures:

- dirty items are loaded into the drum, previously checked to ensure that there are no small items in the pockets that could cause damage;

- washing powder is poured into the tray;

- the desired program is set. You must first check the labels on clothing containing information about the temperature conditions for water procedures. This rule should not be neglected so as not to spoil things;

- the start button turns on.

The washing begins, and we can only wait for it to finish.

Many modern devices have a special timer that activates the process at the time you need. The washing machine can operate in various modes:

- delicate;

- wash wool, cotton, synthetics;

- manual;

- intense;

- fast and daily.

Another important detail is that before loading the drum, items are sorted by type of fabric, shade, and dirtiness. This guarantees good washing quality and reduces the risk of clothing rips and wrinkles.

How is the process organized?

You have installed the necessary modes; no further participation is required. The unit will automatically collect the required amount of water and begin washing. The receiving tray is washed with water jets, and the powder enters the drum. The water heating element sets the desired temperature automatically. The drum begins to rotate, the items are moistened with a soap solution, from which the contaminated areas are gradually washed off.

Working principle of the device

Washing machines today come in two types - vertical and front loading. Let's look at the work of the parts in each of them.

The need for a drum

This is an important element, considered the central part of the machine. As soon as the process is activated, the drum rotates, things are filled with water supplied through numerous holes. Washing in soapy water occurs mechanically. The process is similar to hand washing, only the machine does everything itself, without your help.

The influence of the tank on performance

An important detail located around the drum. Can be made of enameled or stainless steel or plastic. The main purpose is to collect water.

As follows from the statistics, stainless steel elements last the longest if they are properly cared for.

Rinse and drain water

The main task is to remove residual detergents.If your body is sensitive to chemical compounds, it is recommended to use the “extra rinse” function.

The program sends a signal to the drain pump to pump out soapy water, which begins to gradually be removed from the tank. Clean liquid is taken, no powder is added. Water enters the tank and the drum rotates. Once the process is completed, the waste liquid is drained again. Finding out if the pump is working is quite simple. During draining, characteristic sounds will be heard.

Push-up

Everything happens simply. The drum rotates at maximum speed, due to the action of centrifugal force, things adhere to its walls. The moisture coming out of them flows through the drum holes, while the pump works for pumping.

The spin speed can be adjusted by the number of revolutions. If it is necessary to receive items in a dry state, the maximum number of rotations is set. Remember that spinning is an active and noisy process.

Finishing the wash

Once all of the above steps have been completed and the spin cycle is completed, the process is considered complete. Stopping the washer will notify you that the wash was successful. All that remains is to open the hatch to remove the laundry and turn off the device by pressing the “off” key.

Features and characteristics of machines

The most important technical parameters of washing machines include:

- loading method;

- class of electrical energy consumption (indicated by letters);

- number of loaded items (household version - from three to five kilograms);

- additional functionality provided by the manufacturer: tank coating, increased level of efficiency, LCD display, light and sound signals that duplicate each other.

Based on loading options, the machines are divided into two groups, and it is impossible to say unequivocally which is more convenient. In the case of the frontal version, it is possible to observe the work process through the glass of the loading hatch, but vertical models are more compact; they are recommended to be installed in combined bathrooms of small rooms.

In terms of electricity consumption, many models have long been competing with each other in group “A”, being characterized by increased efficiency.

Washing volumes will depend only on the consumer. For a small number of people, a unit with a three-kilogram load is enough; large families should give preference to more spacious models that can wash both a down jacket and a blanket.

There is also a difference of opinion on the issue of options. Naturally, the washing process with their presence is greatly facilitated, but there are concerns associated with diagnosing stages that become dependent on automation and can fail at the most inopportune time.

Experienced craftsmen assure that the simplicity of the device guarantees fewer malfunctions.

Useful tips

If you are just going to make a useful purchase for your home, we advise you to pay attention to certain features:

- Check the material from which the washing machine drum is made. It is best to choose a model with a stainless steel element;

- check the maximum drum speed;

- check that the machine has functions for drying clothes and rinsing them;

- select the optimal drum volume and the maximum program list.

Even the high cost of some models does not reduce their popularity. This is due to certain advantages:

- free time is saved;

- gentle washing is performed in the set mode;

- the software has great capabilities;

- low electricity consumption.

With the help of such modern equipment, you will not have to waste precious time to bring things into proper condition.

Conclusion

Having studied the structure of the washing machine and the principle of its operation, knowing how to check this or that element for operability, you can always carry out routine repairs yourself, without involving service center specialists.