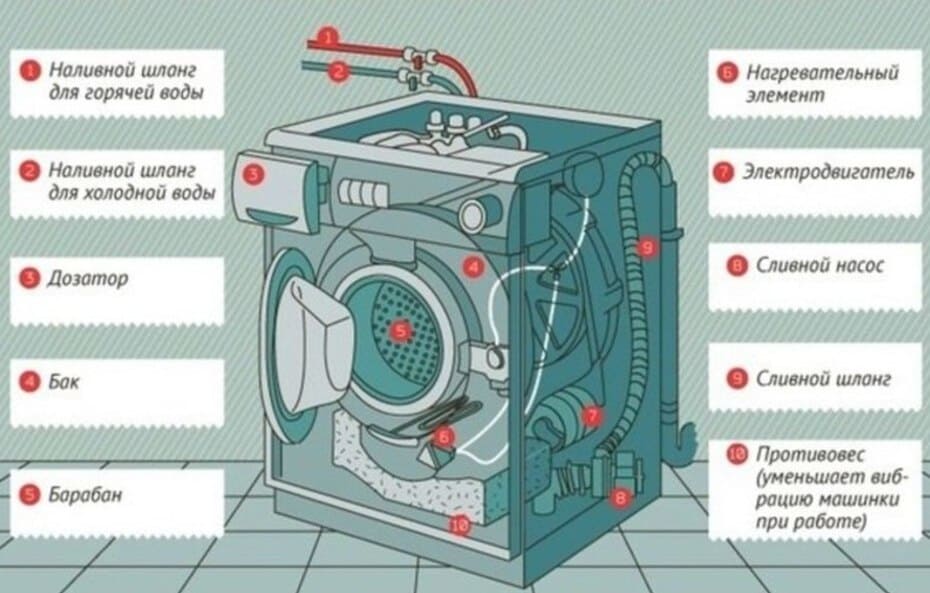

Today, a washing machine is found in almost all homes, and a modern housewife can no longer imagine her life without it. This technique helps a person take care of clothes; most models have various additional options that allow you to save energy during washing. But how it works is still a mystery to many. For those who are planning to independently repair the components of their washing unit, it would be useful to know the structure of the washing machine.

Basic elements of an automatic washing machine

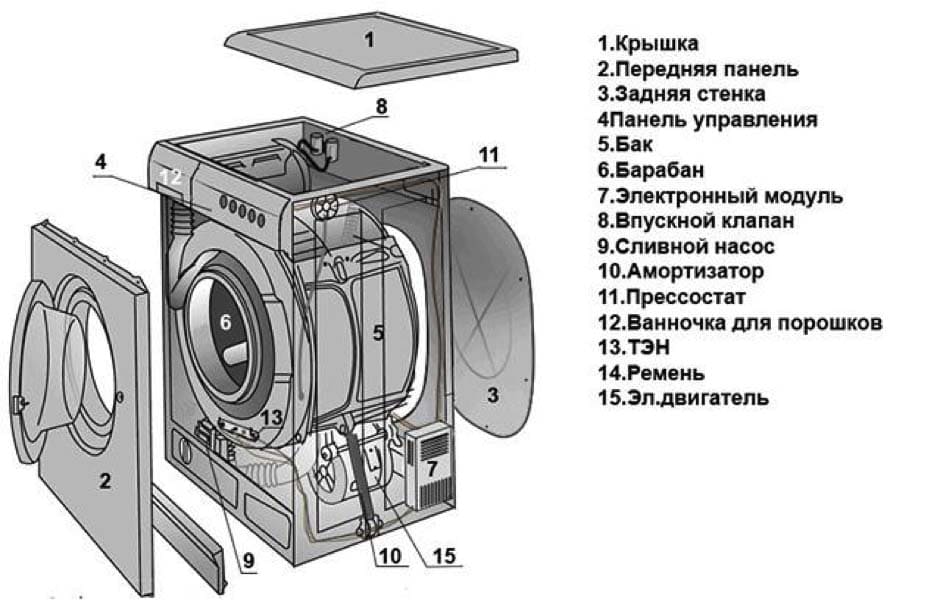

Modern automatic washing machines operate on the same principle, regardless of the brand or manufacturer. But some may differ in engine type, loading method and additional features. Let's look at the main elements of the unit in more detail.

Electric motor

The equipment's centrifuge rotates using an electric motor.The operation of any of them is based on electromagnetic induction. Despite the large number of electric motors, the following are used in washing machines:

- Collector.

This is a subtype of DC motors that can also operate on alternating current. Its active use began in the 90s, but already by the 2000s. The electric motor was completely replaced by two-phase asynchronous devices. The basis of the commutator motor is a stator, a rotor, a tachogenerator of an aluminum housing and several brushes so that the rotor can contact the motor. The brushes are not universal; they quickly wear down on the commutator, and, as a result, periodically require replacement. The main advantages of the motor include: compactness, high starting torque, versatility, simplicity of the main electrical circuit, lack of connection to the mains frequency, smooth speed control. Significant disadvantages are the short service life, high noise level during operation and the need for periodic replacement of brushes. The commutator-brush assembly breaks down much more often than other parts. This is due to the fact that friction in this area causes sparking, causing overheating and separation of the collector lamellas from the insulator.

This is a subtype of DC motors that can also operate on alternating current. Its active use began in the 90s, but already by the 2000s. The electric motor was completely replaced by two-phase asynchronous devices. The basis of the commutator motor is a stator, a rotor, a tachogenerator of an aluminum housing and several brushes so that the rotor can contact the motor. The brushes are not universal; they quickly wear down on the commutator, and, as a result, periodically require replacement. The main advantages of the motor include: compactness, high starting torque, versatility, simplicity of the main electrical circuit, lack of connection to the mains frequency, smooth speed control. Significant disadvantages are the short service life, high noise level during operation and the need for periodic replacement of brushes. The commutator-brush assembly breaks down much more often than other parts. This is due to the fact that friction in this area causes sparking, causing overheating and separation of the collector lamellas from the insulator. - Asynchronous.

It can be two- and three-phase. The production of two-phase ones was discontinued back in the 2000s; they were replaced by more modern and compact three-phase devices that allow frequency control of speed. Such motors consist of two parts: a stator and a rotor, a drum, that causes rotation. The rotation speed can reach 2800 rpm.The most common failure is considered to be a weakening of the torque, which causes the drum to become unstable, may sway to the sides and not perform full rotations. The main advantages of use include: easy repair and maintenance, most often it is enough to simply lubricate the bearings and replace the motor, absence of noise during operation, simplicity of design, affordable price. The only negative is the large size of the motor, difficulty in controlling electrical circuits and low efficiency. Most often, such electric motors are found in budget washing machines.

It can be two- and three-phase. The production of two-phase ones was discontinued back in the 2000s; they were replaced by more modern and compact three-phase devices that allow frequency control of speed. Such motors consist of two parts: a stator and a rotor, a drum, that causes rotation. The rotation speed can reach 2800 rpm.The most common failure is considered to be a weakening of the torque, which causes the drum to become unstable, may sway to the sides and not perform full rotations. The main advantages of use include: easy repair and maintenance, most often it is enough to simply lubricate the bearings and replace the motor, absence of noise during operation, simplicity of design, affordable price. The only negative is the large size of the motor, difficulty in controlling electrical circuits and low efficiency. Most often, such electric motors are found in budget washing machines. - Direct drive.

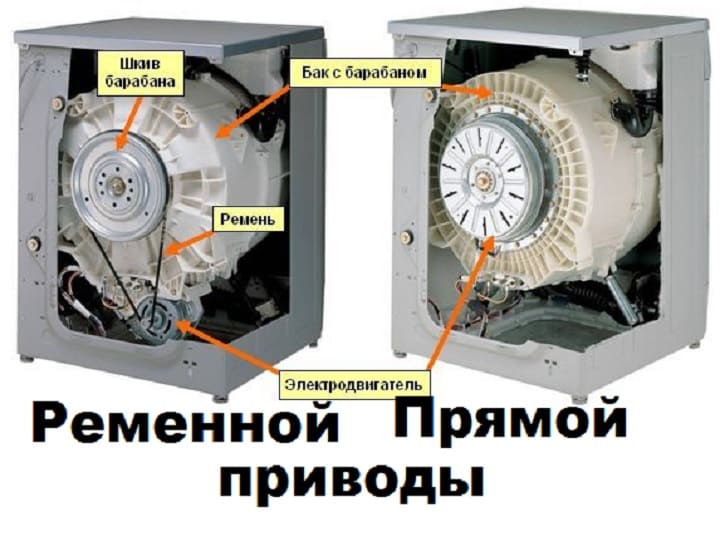

It is also known as brushless motor or inverter motor. Its widespread use began in 2005, and since then, due to a number of advantages, such as compactness and durability, it has firmly established itself as a leader. The motor consists of a stator and a rotor. The operating principle is based on a drive that is connected directly to the drum, which eliminates the need to use the most vulnerable parts of any engine - connecting elements. The main advantages include: simplicity of design, ease of use, low noise level during operation, compactness, high efficiency.

It is also known as brushless motor or inverter motor. Its widespread use began in 2005, and since then, due to a number of advantages, such as compactness and durability, it has firmly established itself as a leader. The motor consists of a stator and a rotor. The operating principle is based on a drive that is connected directly to the drum, which eliminates the need to use the most vulnerable parts of any engine - connecting elements. The main advantages include: simplicity of design, ease of use, low noise level during operation, compactness, high efficiency.

The main disadvantage is considered to be a rather complex control circuit, which increases the cost of such washing machines several times.

heating element

This is an electric heater designed to heat water coming from a hose connected to the central water supply. It is made from a V- or W-shaped tube. Inside there is a conductor element that has a high resistance, thanks to which the heating element is able to withstand overheating and high temperatures.Around the spiral there is a dielectric insulator, which absorbs the heat coming from the heating element and transfers it to the outer steel part.

Next to the working spiral there is a thermal unit that measures the level of water heating in the tank. When a command is given through the control panel in any mode, the heating element begins to work. It gets very hot, and due to heat transfer, the water in the drum is also heated to the desired temperature.

In the event of a breakdown, knowing where the heating element is located is extremely important, since the speed of repair depends on it. Therefore, the user needs to look behind the back panel and check the size of the cover located there. If it is large, then the heating element is often located directly under the washing tub. In this case, to get the heating element, you need to unscrew the back wall. But if the cover is small, it is often used as a hatch that leads to the belt. In this case, the heating element is located directly behind the front panel.

Drum and tank

In practice, these two concepts are often confused with each other. The laundry is loaded into the drum, and the tank is used as a container for water with powder added to it, which gets inside through perforated holes.

Any drum, regardless of brand, is made of stainless steel with a perforated side surface. The main advantage of this material is its high reliability. With tanks the situation is a little more complicated, since they are made not only from different materials, but also give the products different shapes. You can find plastic, stainless steel and enamel tanks on sale. The latter was discontinued not long ago due to low resistance to chipping and mechanical damage.While plastic is becoming increasingly popular due to its lightness, quiet operation and high corrosion resistance.

Cuff

In simple words, a cuff is a rubber seal that is installed in the area of the washing machine hatch. It provides sealing during the process of clogging the tank during operation of the equipment. This is why water does not flow out.

The location of the part is affected by the model of the washing machine. In front-loading washing machines, it has a round shape and is needed to connect the tank to the front wall. When loading vertically, the seal has a rectangular shape and connects the tank and the top wall.

Dispenser tray

Usually, in modern automatic washing machines, regardless of the type of load, a special compartment is built into which powder and washing conditioner are added. When loading horizontally, the dispenser tray is located at the top, close to the control panel. When loading vertically, the hatch must be opened before reaching the powder compartment. The dispenser can be located directly on it or next to the hatch.

In most devices, the tray is divided into three parts, the purpose of each can be determined by the sign painted on it:

- Roman numeral I or Latin letter A: stands for prewash tray. Powder is poured here if the washing takes place in two stages. So, the detergent will enter the drum at the first stage.

- Roman numeral II or Latin letter B: also designates the main wash compartment, and it does not matter which program the user has chosen.

- A flower or star is a compartment designed for conditioner or rinse aid. Such products are usually sold in liquid form, and they are poured both during the haircut and at the very beginning.It is important to do this before the machine starts to fill with water for rinsing. Otherwise, the product simply will not get into the drum.

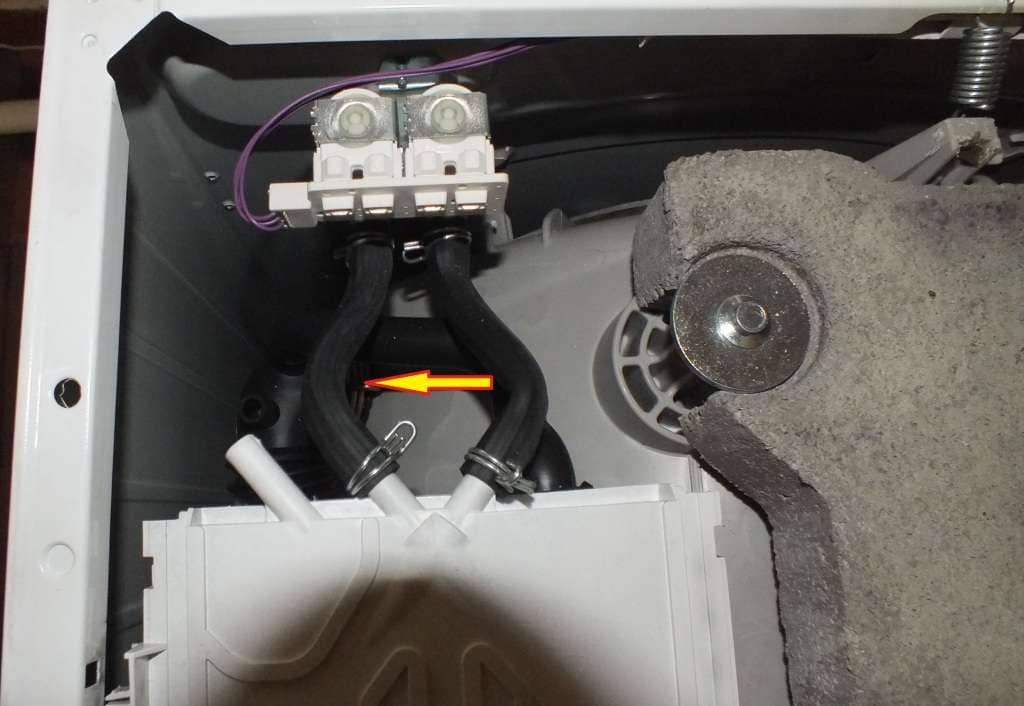

Water supply system

It includes an inlet valve, an inlet filter and pipes that connect the dispenser to the hose through which water enters the tank. The purpose of the inlet filter is to prevent large debris from leaking from the water supply into the machine. It is located in the same place where the water supply hose to the device is attached. This is often a round, metal or plastic mesh. The inlet valve is needed to supply water to the tank and dispenser, it also stops its flow.

Water drain system

The main purpose of the drainage system is to discharge dirty water into the sewer system.

Its installation can be carried out in different ways:

- Using a siphon. If the equipment will be in the kitchen, then the most rational solution is to connect it to the drain using a siphon. This will ensure drainage not only from washing equipment, but also from other devices. In this case, replace the simple siphon with a combined one, which has more options for drainage. Such products are used when installing sinks, washing machines and dishwashers.

- Using plumbing. A curved plastic latch is found in almost every machine today. Its main function is to secure the drain hose to the edge of the toilet, washbasin or bathtub.

- Horizontal outlet. Many apartment owners install a horizontal drain, directing it under the bathroom, directly into the sewer pipe. This method has one significant drawback - an unpleasant odor in the room, the drain hose and inside the device.

- Direct connection.If the point of entry into the sewerage system is far from the washing machine, then you will have to install a branch leading to the installation site.

Electronic module, sensors and control panel

The control panel is responsible for all processes occurring in the washing machine. Using buttons, the selected commands are transmitted to the center of the device - the electronic module. It is he who is the “brain” of the system and manages all stages of washing, giving the necessary commands to all components. This became possible thanks to the memory, which has built-in special programs and functions. Their diversity is influenced by the user himself, choosing a budget or, conversely, an expensive model. To effectively monitor the operation of the machine, the module interacts with sensors: pressure switch, thermostat, tachometer, hatch closing sensor, etc.

They transmit information from different components of the washing machine. It can be displayed on the display located at the top, or displayed using light indicators, it all depends on the device itself. Today, modern washing machines are equipped with a liquid crystal display, which displays the washing process and errors made during the process. Moreover, in models with front loading, the control panel is located on the front wall, and in vertical ones - on the top panel.

Balancing system

The tank and drum are large in weight and volume, so strong vibration is felt during washing. To reduce it, a system of counterweights is built into the body of the washing machine - concrete blocks fixed at the top and bottom of the tank. They reduce noise and vibration that occurs during the process.In addition, shock absorbers are installed on the tank, and special springs hold it at the top, which also reduce vibration.

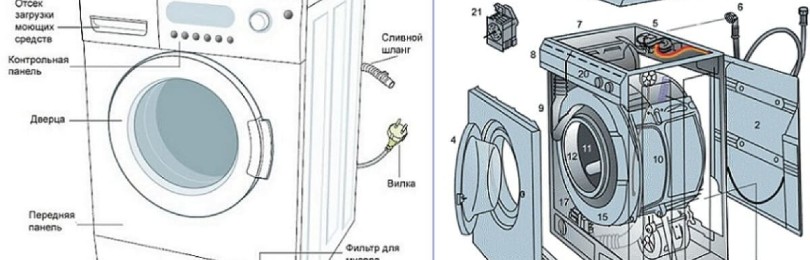

Washing machine body and its components

Its design is quite simple - front, back and two panels on the side, top cover. The front part consists of a hatch door, a lock and a rubber seal. Some models have a small window on the door through which items can be added during washing. As mentioned earlier, the cuff ensures a tight fit of the door and protects against water penetration outward. The lock mechanism is directly connected to the control module, which prevents the door from being opened while the device is washing. At the bottom of the panel there is a small door behind which the drain filter is hidden. The back panel is most often solid.

Features of top-loading washing machines

Horizontal loading equipment is used everywhere, but many users choose vertical loading devices because they have a number of advantages. First of all, it is compact in size, allowing the unit not to take up much space and fit perfectly into the interior.

The main difference between this type of machine is that the loading lid is located vertically. Such devices do not have a transparent door in the front part. In addition, today there are washing machines on sale that use special mechanisms that are responsible for stopping the drum with the flaps facing up when the wash is finished.

The second feature of such devices is two equally located shafts on both sides of the drum, responsible for rotation. The control panel is also located differently, on the rear of the loading hatch.The permissible weight for washing items that can be loaded is determined by standard rules for all similar devices from any manufacturer.

Pros and cons of a top loading washing machine

Vertical washing machines have both advantages over front-facing models and lose to the latter in some aspects.

Advantages:

- Small size. The laundry capacity of the two machines is the same, but the dimensions of the vertical devices are much smaller. So, they can be used in apartments with limited space.

- Even if the wash has already started, you can look into the drum of the top-loading device, which allows you to add items at any stage of the wash.

- Ease of use. Top loading makes loading laundry much easier. The user does not need to constantly bend down and sit down.

- Child protection. Since the control panel is located at the back, it will be more difficult for children to reach.

- Noise protection. Vertical models vibrate less during spinning, which means the noise level will also be low.

- Long service life. Two bearings on which the drum is supported reduce the risk of equipment breakdown due to overload.

Minuses:

- The price of such devices is much higher compared to front-loading models.

- A little variety.

- It will not be possible to integrate the machine into a kitchen set or other furniture structures.

Design of activator washing machines

They were used long before automatic washing machines came on the market. Despite the fact that modern devices are equipped with a number of useful functions, activator-type units can still be found on sale. Activator washing machines are:

- Simple.These are machines with manual spinning and without additional functions.

- Semi-automatic machines with a centrifuge for spinning clothes. They can be equipped with additional functions, for example, water heating or delicate washing.

- Automatic washing mashines. The main difference is in the washing mechanism (an activator-impeller is used). Water supply, rinsing and spinning are performed by the unit independently; the user only needs to select the appropriate program.

The design of activator washing equipment includes 4 main parts. Tank, electric motor, activator and timer. An activator is a plastic part with ribs or blades, the main task of which is to rotate the laundry and water inside the tank. The torque is transmitted to it by an electric motor.

An asymmetrical blade activator is built into inexpensive machines of this type that do not have additional functions. It is a cone-shaped screw that rotates inside the tank clockwise and mixes the things inside. They wash out quite quickly, and the design itself is simple and reliable. The main disadvantage is that when washing this way, the laundry often clings and gets stuck inside the tank, which can cause it to become unusable.

Modern models have an impeller built into them - a bell with symmetrical ribs that differ in size. It is able to change the rotation speed and trajectory of movement. Large blades allow you to create a powerful funnel flow. Medium ones are needed for working with delicate fabrics, and very small ones, located around the perimeter, create additional water flows that allow you to efficiently remove stains and dirt of various kinds. The main advantage is that the complex trajectory of movement will prevent the laundry from twisting.To get started, you need to put things in the tank, pour water at the desired temperature and add laundry detergent. Upon completion, the dirty liquid must be drained and clean liquid must be collected for rinsing.

Pros of use:

- There will be no problems with foam formation during use.

- Simple semi-automatic models can significantly save water.

- Budget equipment that is not equipped with a heating element allows you to save energy. This is due to the fact that water is poured into it already heated to the required temperature, and the machine spends electricity only on operating the engine.

Minuses:

- Budget models do not have a spin cycle.

- The input is drained manually; it needs to be changed periodically, which is very inconvenient.

Operating principle of the washing machine

The concept of the washing machine is quite simple - it mixes water in which powder and clothes have been added to remove any dirt and stains. Let's look at what happens during one wash cycle:

- After selecting the desired function and turning on the machine, the door lock is activated: once the door is closed, the user will not open it until the wash is finished.

- Once the door is closed, the inlet valves open, allowing water to flow into the drum. Along the way, it passes through the detergent tray, collecting detergent.

- The water entering the drum compresses the air in the pressure chamber. Thus, the pressure is transmitted through a flexible pressure pipe to a relay, which moves the inlet valves to the programmed water level.

- The heating element begins to heat the water to the desired level.

- The motor starts, driving the drum at approximately 55 rpm. This speed is considered the best for washing clothes.

- The engine turns off and the pump starts running to drain the dirty water and bring in clean water for rinsing.

- The pump is turned off and the rinsing process begins.

- The final stage is spinning. The motor is turned on and rotates the drum at high speed. At the same time, the pump operates to remove water.

- The motor is turned off. To stop the drum from rotating, the door lock is disabled. The wash is now finished and the door can be opened.

A variety of programs, such as delicate wash, color wash or pre-soak, is one of the features of washing machines. Specifically, automatic ones, which give the user choice when it comes to how they want to wash their clothes. If you need a certain temperature or you are washing delicate fabric, then the programs will help you find the optimal conditions for washing your items.

Rules for caring for your washing machine

To extend the life of your washing machine, you need to take care of it, since the equipment is used almost daily to remove stains from your clothes. A few simple tips will ensure the unit is in good working order:

- Cleaning. If you feel that your clothes could look much cleaner or the inside of the drum smells unpleasant, it is recommended to use special powders to clean the device once a month. Simply run the machine empty after adding powder.

- Open the door. Here's another life hack you may have never heard of. Leave the door or lid of the appliance open after each wash. Why? This will allow moisture accumulated inside the drum to evaporate.

- Keep any liquids away from the control panel. Air conditioners, detergents and stain removers can damage it if handled carelessly.

- Wipe the machine inside and out. It is important to wipe down the exterior of the unit approximately once a week. For this, it is preferable to use a mild dishwashing liquid. Don't forget about the inside of your device. Wipe the drum periodically with a damp cloth.

- Clean the dispenser. Follow the instructions for cleaning the dispenser in the product manual. Avoid using detergent.

- Keep an eye on the hoses connected to the washing machine. They should not have kinks. If your washer has been around for a long time, it may be time to replace them. By the way, this needs to be done every five years. A leak in one of the hoses can lead to a flood.

- Make sure that only clean washing water enters the machine. The liquid that comes from water pipes contains many chemical impurities that are unsafe for human health. Most people have long been trying not to use such water for food, but do not consider it necessary to change it in the washing machine. But it is the main reason for the appearance of scale. To avoid this, it is recommended to use special filters that purify the water for washing.

- Overload. Too many clothes at once is not a good idea. Overloading the engine causes it to overheat. In addition, this situation may cause poor washing, or the unit will stop working altogether.

- Rust. Sometimes many people notice that clothes have reddish-orange stains after washing. This may be due to rust. Look for rusty spots in the device or dispenser. They can be easily removed by adding two cups of lemon juice and running the machine through one wash cycle in hot water.It could also be that there is rust in the water pipes. Thus, rust particles from the pipes end up in the water you use. In this case, you should check them.

- Take care of your dryer. If you bought a fully automatic machine, there will also be a built-in dryer. Clean it after every wash. Fine particles caught on clothing can clog the filter and restrict air flow, which can cause the dryer to overheat.

Washing machine maintenance

These steps should be performed at least once a month:

- Inspect the detergent tray. If the detergent dispenser clogs due to insufficient water pressure or using too much detergent, the clothes will not be washed properly.

- Cleaning a glass door. Limescale and other particulate matter can allow water to seep between the glass and the seal.

- Seal. If the cuff sticks to your hands, it's a sign that it's time to replace it.