A tunnel dishwasher is professional equipment, which makes it possible to quickly and efficiently wash a large number of dishes of any size with varying levels of contamination. It is used mainly in catering establishments, for example, in cafes or factory canteens. It is characterized by high performance, functionality, durability and impressive dimensions. Let's look at it in more detail below.

A tunnel dishwasher is professional equipment, which makes it possible to quickly and efficiently wash a large number of dishes of any size with varying levels of contamination. It is used mainly in catering establishments, for example, in cafes or factory canteens. It is characterized by high performance, functionality, durability and impressive dimensions. Let's look at it in more detail below.

Key Features

This dishwasher is the most highly efficient of all existing ones - in just sixty minutes of operation it is capable of washing about eight thousand plates and other cutlery.

As a rule, the machine body is made with two walls and a heat-insulating fifteen-millimeter gap. The dishwasher can be used with both cold and hot water supply.

To install a model of such a dishwasher, a fairly spacious room is required, since some units occupy about fifteen square meters. In addition, before installing the machine, you should take into account the volume of water consumed and the sewerage capacity, as well as create the correct connection to a 3-phase power supply network of three hundred and sixty volts.

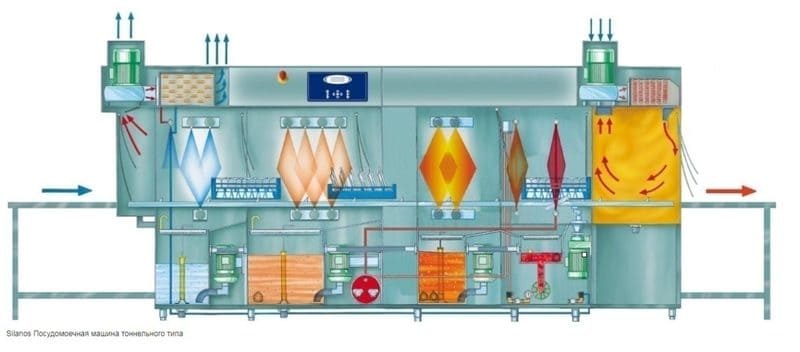

Appearance tunnel dishwashers has serious differences compared to conventional models.These devices are so called because of their design features. They are also called conveyor machines because the washes are similar to a conveyor belt that passes through a tunnel corridor.

Advantages

Such equipment makes it possible not only to process a huge number of dishes in a short time, but also to significantly reduce cash costs, thanks to savings in water consumption, detergents and electrical energy.

Also Dishwasher tunnel type provides competent washing of various kitchen utensils, for example, cups, glasses, plates, saucers, and large containers. On the market today you can find various models that differ in configurations and modifications.

The presented unit guarantees maximum automation of the process of washing a variety of cutlery, and also significantly increases the labor efficiency of workers in the kitchen. So any catering establishment with high traffic should have it at its disposal.

Some tunnel models are equipped with additional surfaces. Certain models, such as the MPT 2000, have a wide variety of options and systems that simplify the operation of the machine.

How it works

Case manufacturing tunnel machine Made from high strength steel, which is resistant to the spread of rust. It is important that it is easy to use and does not require any maintenance measures.

The washing compartment has the form of a hopper with the required amount of free space, which is equipped with several powerful sprinklers that distribute streams of heated water. The water is predominantly heated to fifty-five degrees Celsius.

During the operation of the liquid nozzles, the nozzles with the detergent are also activated, designed for a high-quality cleaning of kitchen utensils.

The drying compartment contains heat fans, with the help of which the dishes become dry in just a few minutes, and sometimes even seconds.

How does it work

Tunnel Dishwasher It operates on a fairly simple principle, which allows you to wash the required amount of dishes in the shortest possible time and without any difficulty.

First, kitchen appliances are placed in a special container, which is placed on a moving conveyor. They are then directed into the working chamber, where they are exposed to strong streams of hot water and detergent.

In the rinsing sector, dishes are treated with a powerful shower to remove remaining dirt and soap solution. After this, the utensils enter the drying chamber, where warm air currents blow over them.

All processes occurring in the working chambers are controlled using equipped sensors. For example, there are sensors that monitor the position of the door, as well as sensors that block the conveyor and other parts.

Varieties

Tunnel dishwashers are divided into finger and cassette, depending on the loading principle. Their main difference lies in the type of kitchen utensils that the unit can wash. In cassette-type models, cutlery must first be placed in special containers, which requires additional space for sorting.

The cassette machine makes it possible to wash dishes of various shapes and sizes. Most often, such a unit can be found in large restaurants or office canteens. It is small in size and can be positioned in a corner.

It is best to connect it to a hot water supply system. Usually, performance of the cassette model equal to one thousand eight hundred units of dishes in 60 minutes. The highest productivity reaches six thousand plates per hour.

In finger models, you only need to place the dishes on the conveyor belt, which helps reduce staff time. It is on the belt that the devices are washed.

Finger models are characterized by the highest productivity - up to ten thousand plates per hour. Even a massive kitchen appliance can be installed on a special tape.

Finger tunnel Dishwasher It is quite compact and does not require much free space for installation.

Most popular models

- The MPT 1700 model is in high demand, the release of which is carried out in both right and left versions. Its productivity is one thousand seven hundred plates per hour. It has separate circulation systems for washing and rinsing liquid. Also equipped with four cassettes for washing plates and two cassettes for cups.

- Quite popular model OZTI OBK 1500, whose productivity reaches 1650 plates per 60 minutes. The washing tank has a capacity of ninety liters. The unit is made from high quality materials.

- Worth noting are Abat machines domestic production. They are sold at an affordable price and at the same time, in terms of ease of use and technical parameters, they are not inferior to most foreign analogues.

- Model Apach ARC100 is one of the best-selling washing mashines not only in our country, but also in many other countries. Its production is carried out from high-strength materials, and the unit itself can process up to one hundred cassettes per hour. This tunnel machine is highly powerful and compact, making it suitable for installation in small establishments. It is easy to wash and can last for a long time without breaking.