When purchasing, many people pay attention primarily to functionality and dimensions. However, the washing machine drum has a great influence on the quality of washing. Its design features will directly affect the safety of things and their service life.

What is the difference between a tank and a drum?

To identify the differences between a drum and a tank, it is necessary to understand these concepts. In the first case, we mean a cylinder used for storing things. It undergoes a cycle of cleaning laundry from dirt; it is located inside the tank. Another container is used to fill the soap solution. Liquid with dissolved detergent enters the drum through special holes.

The following conclusions can be drawn:

- the drum is used to load things, a cycle goes through it;

- The tank is used to fill water; there is a drum inside it.

In addition, there are differences in materials.To make the tank, polymers, metal or stainless steel are used. The drum is always made from only the latest material.

How does a washing machine drum work?

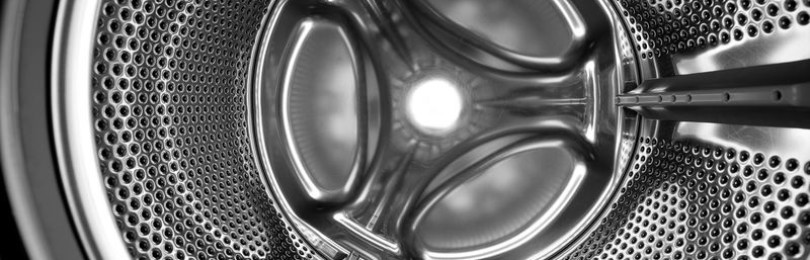

The drum is a container equipped with a hatch on one side. On the other hand, a connection to the motor is provided through a threaded shaft. The inner surface has many holes, which improves the quality of washing.

The drum is made of stainless steel and equipped with strikers. The partitions prevent the laundry from bunching up and, in addition, they improve the quality of cleaning. They come in various types; manufacturers make them straight or curved. The second type is preferable, as it allows you to place things more evenly inside the drum. Typically, plastic is used as the material for the fins.

They are hollow inside, and some manufacturers provide them with holes. Water is poured into them when the striker is immersed in water. When the drum rotates, it rises up. Then the water that gets inside the hole is poured onto the laundry. This improves stain removal and rinsing performance. The drum itself is hidden inside the tank, to which it is connected using a pulley.

Drum operating principle

Starting the program starts the water collection process. The signal to the intake valve is supplied by an electronic module. Then the valve is lowered, water enters the drum and powder tray. The valve closes after the container is completely filled. The water level is controlled through a pressure switch, which sends a signal to the module. When the drum is full, the heater starts working. It brings the water to the temperature of the selected mode.

After this, the drum begins to rotate, and powder dissolved in water comes out of the tank.Moreover, the number of revolutions and direction change, depending on the washing stage and the selected program. Due to rotation, the things inside the drum are constantly moving.

They rub against the surface, gradually freeing themselves from contaminants. The number of revolutions reaches its maximum during the spin cycle. Thanks to centrifugal force, things can be rid of excess moisture. The squeezed water is pumped into the sewer using a pump.

What materials are washing machine drums made from?

When buyers are interested in drum material, they usually mean the tank. It really comes in different forms - plastic, steel or enameled. And the drum can only be made of stainless steel.

Today the market is filled with models with plastic and stainless steel tanks. And options with an enamel part have recently been taken out of production. Although they had good technical characteristics, shortcomings in operation forced brands to abandon them.

Enameled tanks were, on the one hand, stronger, as they were made of metal. They did not crack during transportation and exposure to high temperatures, unlike plastic options. However, polymer parts were more advantageous due to their resistance to corrosion.

Enameled tanks often became unusable within a short time after purchase. The reason is a violation of the protective layer. When even small cracks appeared, the corrosion process began. After all, under the enamel layer there was hidden metal, which was easily destroyed by constant contact with moisture.

As a result, the tank needed to be replaced with a similar one, since due to corrosion the part began to leak water.Such replacements resulted in large sums of money, which led to the lack of demand for models with an enamel tank. Manufacturers had to curtail production as buyers preferred to choose stainless steel or plastic options.

In addition, some companies have decided to use tanks made from two materials at once. For example, the ARDO brand produces the back wall from stainless steel, and the side parts from polymers. This move allows you to make the most of the advantages of materials, while reducing their disadvantages.

Such tanks are lighter than counterparts made entirely of stainless steel. On the other hand, they are stronger than purely plastic models. In addition, this solution reduces production costs. Therefore, washing machines with such a tank are cheaper.

Models from the budget segment usually have a plastic option. Moreover, all composite polymer materials fall under this category. Many manufacturers use their own developments that improve and supplement the standard formula.

The basis is polypropylene made of calcium carbide. This provides the tank with resistance to chemicals that are found in abundance in powders and conditioners.

Polymer materials from different brands will differ in technical characteristics. For example, carboran from Electrolux has good thermal insulation. In addition, the spin cycle will be quieter, since the material dampens vibration and noise well.

Other materials include:

- carbotech and polytenax – Gorenje supplies its products with such tanks;

- polynox – found in washing mashines from Bosch and Siemens;

- fibran – used for the production of Whirlpool equipment;

- carferron – installed in BEKO washing machines;

- silitech - used for the production of Candy products.

Pros of a plastic tank:

- not susceptible to corrosion;

- reduction of noise level when rotating the drum;

- saving on electricity consumption;

- resistant to chemicals.

The main disadvantage is fragility. Improper transportation is especially dangerous, since any impact can cause the tank to split. In addition, loss of integrity can occur due to misuse. For example, if after delivery of the washing machine the transport bolts were not removed. Then, when washing, the tank will be damaged, which will require replacement.

Now 90% of models on the washing machine market have a plastic tank. And stainless steel parts are typical only for the premium segment. For example, the Miele brand produces only such tanks on the market, but the cost of the products is extremely high. Typically, the price tag for stainless steel washing machines starts from 65,000 rubles.

Advantages of stainless steel:

- strength, the tank will remain undamaged during transportation;

- reliability, high quality steel products can last up to 100 years;

- chemical resistance, detergents will not destroy the tank;

- moisture resistance, due to constant contact with water, corrosion does not form.

Disadvantages of a steel tank:

- increased noise level during washing;

- high energy consumption due to poor thermal conductivity.

Types of internal surfaces of drums

Companies are constantly developing new programs and modes that improve the quality of washing. Design features are also subject to changes. To reduce the wear and tear of fabric from constant friction, manufacturers make drums with a special surface. As a rule, they are all patented and have a brand name.

Drums with holes

Any drum has perforations, as water and detergent enter through the holes. In addition, the safety of the laundry directly depends on the size. Too large will provide a large influx of water, which will wash away the foam prematurely. The clothes simply won’t have time to get cleaned during the cycle.

And if the perforation is too small, the laundry will not be wetted well. The ideal balance is an abundance of small diameter holes. This guarantees a low degree of wrinkles and gentle washing. In addition, a drum with this design will be much more durable. Fine and frequent perforations protect the tank from small objects that may remain in pockets.

This type of drum can be found at Candy, and the brand uses larger containers. Unlike standard parts, the number of holes in them is increased by 9%. Their total number in washing machines with a depth of 40 cm is 2556, and the size itself is reduced to 3 mm.

Advantages of this design:

- good level of rinsing, all foam is washed out completely, so the laundry does not have streaks;

- protection of linen from damage, as things do not cling to the perforations;

- effective stain removal, as water and powder are supplied in full.

Drip drums

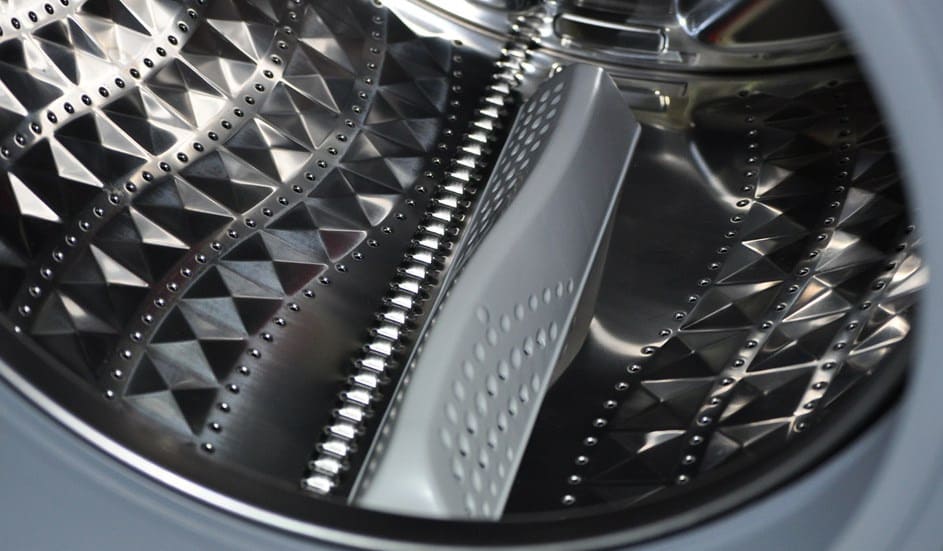

Drums with special protrusions in the shape of drops are produced by Bosch. The brand name of this coating is VarioSoft. On one side the protrusions are gentle, on the other they have a steep appearance. This ensures both gentle washing and removal of stubborn stains.

To clean delicate fabrics, the technique starts a rotation that affects the shallow part of the droplets. And for washing ordinary things and when heavily soiled, the laundry comes into contact with a steep surface.

Pearl Drums

Pearl Drums are installed in Hansa brand machines. The development provides protection for laundry even when spinning at speeds up to 1400 rpm. Gentle washing is ensured by a surface strewn with hemispheres of different diameters. This prevents clothing from being pulled into the openings on the drum.

Honeycomb drums

The drums, the surface of which is made to resemble a honeycomb, are an innovative development of the Miele brand. Therefore, it cannot be found in washing machines of other brands. Honeycomb drums, on the one hand, help protect laundry from damage. On the other hand, reduce electricity consumption per cycle.

This is achieved due to the structure of the honeycomb: hexagons have a convex design. Therefore, when washing, a water surface is formed, protecting clothes from damage. The perforation inside the tank has a small diameter - this ensures better and more gentle washing.

On the one hand, the detergent stays inside the tank longer. On the other hand, the fabric does not receive puffs or other damage when washed. After all, the holes are too small for laundry to catch on them. The absence of welded parts increases the service life of the drum.

Drum sizes

The size of the drum is directly dependent on the volume of laundry loaded. Now manufacturers supply the market with models designed for washing from 3 to 12 kg. However, water consumption increases in proportion to the volume of laundry loaded. Therefore, washing machines that can hold a large amount of laundry are not very economical.

The size of the hatch also depends on the loading volume, so models with a spacious drum also have larger doors. When choosing such models, you need to pay attention to the build quality, because the parts will bear an increased load.It is worth giving preference to models manufactured in factories in Europe, Korea and Japan.

What can be the rotation speed of the drum?

Modern motors allow spinning at 1600 rpm. The maximum rotation speed of the drum allows you to rid your laundry of excess water. Although a good spin can reduce the time until complete drying, it can also cause damage to the fabric.

After all, the clothes, while rotating, get stuck in the holes on the drum, which leads to ruptures. Therefore, you should give preference to models with a convex inner surface. Such tanks provide gentle washing and spinning.

What drum parameters should be considered when purchasing washing equipment?

Before purchasing, you must carefully inspect the product:

- The fixation of the tank and drum must be reliable, since the structure should not swing much when moving. Otherwise, the internal parts may be damaged during washing.

- The surface of the drum and strikers must be smooth and polished, without nicks.

- There should be no chips or dark areas on the drum.

- The assembly quality should be at a good level: the bolts should not protrude, the crosspiece should be installed correctly.

Reasons why the washing machine drum does not rotate

The drum stopped working for several reasons. To identify a malfunction, it is necessary to inspect the equipment. However, before diagnosing, you need to perform several steps:

- forcefully terminate the loop or wait until it ends;

- disconnect the machine from the power supply;

- drain the liquid filling the tank;

- remove the laundry from the drum;

- dismantle the rear wall.

The drum movement may stop due to:

- Foreign object. Forgotten items sometimes end up in the space between the tank and the drum.These objects either wrap around the shaft or get stuck between the walls, causing a stop.

- A belt that is damaged or has fallen off the pulley. The drum stops rotating because there is no connection between the elements. After all, it is the belt drive that sets the tank in motion, transmitting impulses from the motor.

- Broken engine. Due to a motor malfunction, the drum may also stop rotating. Failure to operate can be caused by wear of the brushes, short circuit of the winding turns, or damage to the current supply contacts.

- Seized bearing. Usually the problem occurs in washing mashines that have been in service for more than one year. Over time, the seals begin to leak water, which leads to corrosion. As a result, the bearing jams when the cycle starts.

- Overload. Each machine can wash a certain amount of laundry per cycle. If these limits are exceeded, damage to the mechanical components of the device occurs. Most brands provide models with special sensors. They allow you to control the weight of loaded items. If there is an overload, the display shows an error code.

- Control module failure. The drum may stop rotating if it stops receiving signals from the buttons on the panel. This can happen due to damaged contacts, poor quality of microcircuit components, mode failure, or when the supply current parameters do not meet the required ones.

- Opening the flaps during the washing period (in machines with vertical loading). May cause damage to the heating element and breakdown of the tank. Sometimes the doors swing open spontaneously, but often this is due to inattention. Most users do not close them all the way, which causes them to open when washing.

Conclusion

It is better to select a drum with fine perforation, but with an increased number of holes. In addition, the surface must be equipped with special convex areas. Typically, every brand has such drums. Cellular drums from the Miele brand are especially popular. They will ensure gentle washing, as they will prevent fabric from getting into the perforations. When purchasing, you should pay attention to the assembly and integrity of the product. As for the tank material, it is better to give preference to stainless steel.