Sometimes owners encounter a malfunction in which the Indesit brand machine does not take in water or constantly pumps out liquid without starting the washing process. At the same time, a warning indication is triggered or a notification is displayed. The owner can find and eliminate some of the defects on his own, but some breakdowns can only be corrected in a service center.

- Sometimes the Indesit machine pumps out liquid without the washing process.

Features of the Indesit washing machine

The equipment is equipped with a solenoid valve with a level sensor that determines the amount of water in the tank. The sensor works in conjunction with the control unit; contaminated liquid is pumped out using a vane pump.

Common reasons why the machine does not fill with water

Problems when collecting water arise due to clogged lines or breakdown of components responsible for maintaining the liquid level. The owner can check the elements sequentially and quickly restore the functionality of the equipment. Maintenance should be carried out with the power turned off and the water supply taps closed.

Input filter clogged

The pressure line contains a mesh that separates mechanical impurities from the water. When the filter becomes dirty, the flow area decreases while the flow resistance increases. To remove dirt, you will need to close the valve on the water main, unscrew the hose coupling and dismantle the mesh located on the inlet pipe of the machine. Filter contamination is accompanied by extraneous sounds when trying to draw water, which arise due to turbulence in the liquid flow.

- A clogged inlet filter may be the reason why the machine does not draw water.

Broken pressure switch

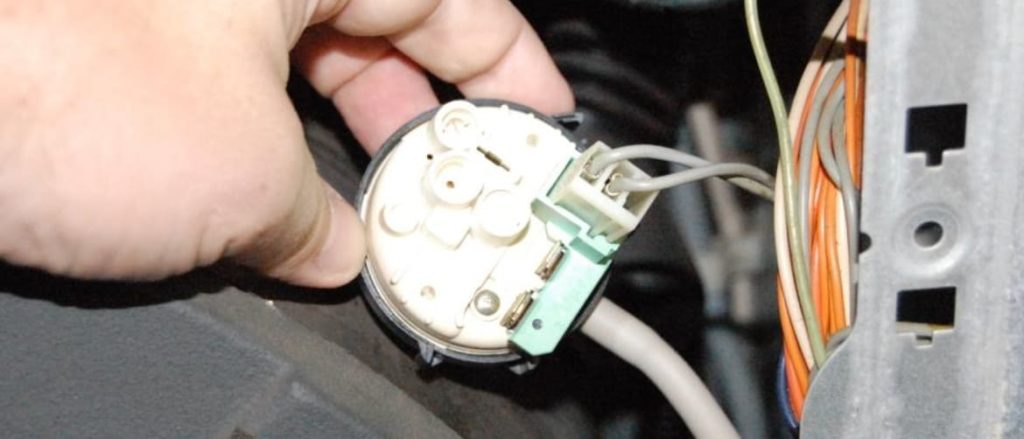

The design of the equipment has a liquid level sensor; if the sensor does not work correctly, the machine constantly drains the collected water without starting the washing cycle. On models equipped with a screen, error code F04 or F07 is displayed. The owner needs to clean the intake pipe from dirt, and then check the sensor by blowing it out. If clicks are heard when compressed air is supplied, then the sensitive element is working.

Sometimes after purging, the performance of the pressure switch is restored. If the sensor does not work, then a new unit must be installed.

Control board problems

If the controller breaks down, codes F17 or H2O are displayed on the screen. Electronics fail due to vibrations, oxidation of tracks due to condensation, or burnout of elements after a power surge. Repairing the controller at home is difficult; to restore functionality, it is necessary to resolder the elements and tracks. If the microprocessor burns out, a new module must be installed, the price of which reaches 60% of the cost of a new machine.

Burnt out pump

To remove contaminated water, an electrically driven pump is used; it is turned on and off according to a signal from the controller. At home, you can check the integrity of the wiring harnesses and the condition of the motor windings. The owner can repair the cables himself, but it is impossible to repair the motor. The drive is made in a single housing with the pump; disassembly is not provided. It is recommended to select and install a new pump in the service conditions.

- An electrically driven pump is used to remove water.

Water supply valve malfunction

The valve design contains an electromagnet that blocks the flow of water based on a signal from the control unit. If an element breaks, the normal circulation of liquid is disrupted; the main sign of a defect is a large amount of dry powder in the tray after washing. To check, you need to get to the valve located under the housing cover, and then check the integrity of the winding with a tester. An alternative test is based on applying voltage to the contacts; a working valve should operate with a quiet click. In the event of a breakdown, a new unit must be installed.

Inlet hose clogged

A rubber hose is used to supply fluid, which can become clogged with rust particles. During prolonged use, the material dries out and partially covers the cross-section. The check consists of removing the sleeve and cleaning it with steel wire. If a dry area is detected, the hose must be replaced. Sometimes the cause of poor water supply is deformed gaskets that block the flow area. The damaged seal is visible when the fitting is removed.

Water supply interruptions

The equipment requires stable fluid pressure in the water main. If the pressure drops or the flow pulsates, the tank is not filled and errors may be displayed. You should check the position of the valve responsible for supplying water to the machine. In case of low pressure, it is recommended to postpone washing, since the process takes several hours and may be interrupted by error notifications.

- If the water pressure drops, it is recommended to postpone washing.

The hatch does not block when closing

The lid design has a lock with an electromagnetic drive and a sensor that prevents the hatch from opening during the washing process. If the wiring harness is damaged or the contacts are oxidized, the system does not work, the control unit blocks the supply of water. The display may show error F17. The repair consists of partially disassembling the housing, installing a new harness or repairing damaged areas of the old one.

Oxidized contacts must be cleaned and covered with a layer of solder; in case of repeated failures, the elements should be replaced.

Self-diagnosis

To quickly troubleshoot you need to:

- Make sure there is water in the underwater hose.Many apartments have a valve installed that shuts off the liquid supply to the washing machine.

- Check that the lid lock operates when the wash cycle is started.

- Remove the hose fitting and make sure there is water supply through the hose.

- Determine error codes by blinking LEDs or reading from the screen, and then decipher the values using the table from the operating instructions. Please note that the same error can be caused by problems with different nodes.

When carrying out diagnostics, it is necessary to check the elements of the route responsible for the water supply one by one. For example, if there is a filter system, there may be a drop in pressure due to clogging of the mesh with rust and small stones. All work related to water mains should be carried out with the apartment taps closed.

.jpg)

- To quickly troubleshoot a problem, you need to make sure there is water.

Problem solving options: repair

Restoring the unit's functionality is done with your own hands or through an authorized service center. The owner can independently eliminate minor defects or reset the error in the control unit, but to carry out a full repair, disassembling the machine is required. If the equipment is under warranty, removal of parts voids the manufacturer's obligations.

With your own hands

The owner can independently restore the water supply by removing contaminants from the filter or installing a new hose. If electronic components or the pump fail, it is recommended to contact a repair service. To carry out correct diagnostics, special equipment is required, which most owners do not have.

Handicraft repair of electronics can lead to complete failure of the washing machine.

If the equipment is under warranty, the owner can perform the following actions:

- Inspect the water supply hose, which may become kinked or kinked if not installed correctly. After the pipeline is laid evenly, water supply occurs without difficulty.

- Fix a one-time software glitch. To clear the error, you need to reboot the control unit by turning off the power for 10-15 minutes. If the problem persists after several wash cycles, a full check of the electronics and wiring harnesses will be necessary.

- Eliminate jamming of the door lock due to dust or misalignment of the rubber seal. It is necessary to open the sash and inspect the socket of the locking mechanism and the hook: there should be no dirt on the surface of the parts. An incorrectly installed edge should be placed on the guide edge. If the lock does not work again, a detailed check of the mechanism and wiring is required.

- The first thing you need to do is inspect the water supply hose.

Call the master

If the owner of the equipment does not have experience in repairing household appliances, then you should invite a technician from an authorized service center. The repair price starts from 1.5 thousand rubles. and depends on the region and complexity of the breakdown. If complex defects are detected, the washing machine must be taken to a workshop for a detailed inspection and subsequent restoration.

Please note that repair costs may exceed the price of new equipment.

For example, restoration of a microprocessor control unit is only possible if the integrity of the getinax base is maintained. When part of the board burns out, elements and tracks are destroyed, such a controller requires replacement.The cost of removal and diagnostic work starts from 2 thousand rubles, to this amount should be added the cost of purchasing spare parts. It is permissible to purchase a used and known-good unit, but there is a risk of rapid equipment failure due to the small residual resource.

Prevention of malfunctions of the Indesit washing machine

To reduce the risk of problems with water injection, you must:

- use anti-scale agents or periodically run a wash cycle without laundry and add citric acid to the tank;

- operate the equipment in accordance with the instructions;

- avoid overloading and align the body using a level;

- install equipment in rooms protected from rodents (mice and rats often damage the insulation of electrical wiring);

- provide bathroom ventilation to reduce humidity and prevent corrosion of contact plates;

- connect the equipment through a separate socket equipped with a circuit breaker for short circuit protection;

- in houses with unstable voltage in the power supply network, provide a stabilizer with suitable power.

Useful tips and general recommendations

To reduce the risk of clogging the mesh, you should install an additional filter that separates mechanical impurities from the water. It is recommended to regularly remove and inspect the rubber fluid supply hose. When the shell is destroyed, the flow area decreases, which negatively affects the filling rate of the tank. If malfunctions are detected, you should carry out diagnostics or invite a service representative who will quickly determine the cause of the breakdown.

For the second week I’ve been struggling with Indesit, which has stood for 10 years, I changed the bearing, it started working, washed the jacket, then it started to fail, now I’m sorting through the water supply until the very end, thanks for the article, I don’t understand why there are two valves, well, one is the main one, the other is topped up? the level sensor has two contacts, one is triggered before the other