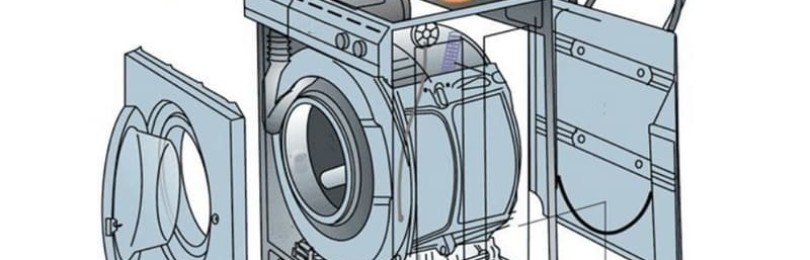

Sometimes a washing machine needs to be repaired. In order to do this efficiently, it is useful to know how it works. Knowing the structure of a Bosch washing machine, you can disassemble and reassemble it, find out its strengths and weaknesses. As you gain experience, you can learn to repair your washing mashine yourself in almost all possible cases.

Sometimes a washing machine needs to be repaired. In order to do this efficiently, it is useful to know how it works. Knowing the structure of a Bosch washing machine, you can disassemble and reassemble it, find out its strengths and weaknesses. As you gain experience, you can learn to repair your washing mashine yourself in almost all possible cases.

Main nodes

This device has many parts that belong to the following groups:

- Those parts that relate to the control panel.

- Various parts of the body.

- Electrical devices, tank and drum.

- Hydraulics.

In the future, each of them will be considered separately.

Control

Group of parts for Bosch washing machine control, consists of the following parts:

- The housing panel, which has a recess for the powder receiver and space for indicators, keys and control panel knobs.

- In order to make it convenient to use the controls, they are provided with an overhead panel with holes for them, on which there are explanatory inscriptions.

- The heart of the control board of a washing machine is a microcircuit that is installed using special fasteners.

- In order to provide power supply, a network capacitor is used. A special protective casing is provided for it.

- Power cord for washing machine.

- The outer panel for receiving the powder is also located here.

- Since different washing algorithms may be required for the laundry, a mode switch is needed. It is located on the control panel, and its internal mechanism is located under its surface.

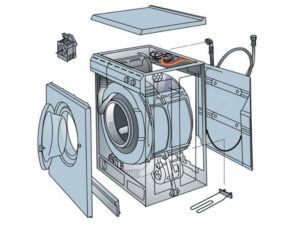

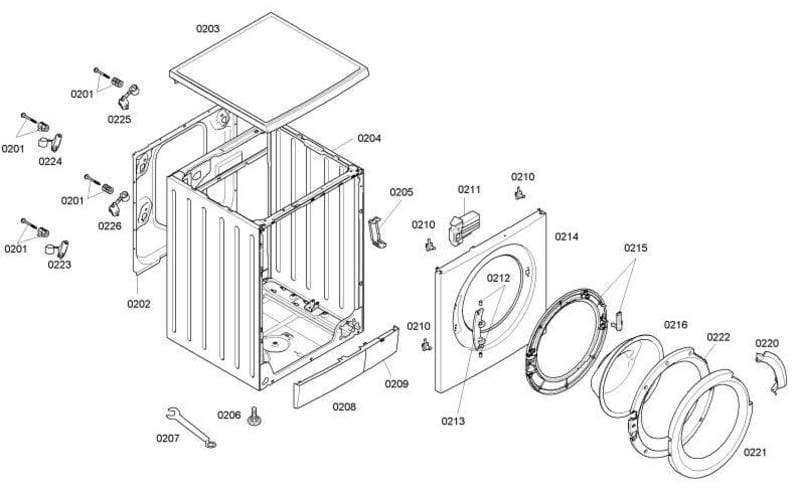

Body

In all Bosch models, there are 28 parts in it. The diagram of their location is the same in all cases, allowing you to easily disassemble these devices without using special tools.

This group of parts includes:

- The top cover of the washing machine.

- Cover for the inlet valve.

- Cover for the service hatch.

- Special fastening for the inlet hose.

- Right transport bolt.

- Left transport bolt.

- The right, left and rear walls of the machine, connected together, are considered as a single element.

- A key that is used to adjust the height of the machine's legs. They can be installed at a certain height, ensuring the correct position of the Bosch washing machine even if it is installed on an insufficiently level floor.

- A tray, which is designed to protect against water leaks. The Bosch automatic washing machine uses the Aquastop protection system. There is a sensor on the tray that is triggered if water gets there.

- Legs, designed in such a way that it is possible to adjust their height. For this purpose, they have a thread that allows them to be screwed or unscrewed.

- Lower short front panel.

- Lower front elongated panel.

- Fastening element for the front panel.

- Hinge for the hatch through which the laundry is loaded for washing.

- A clamp, which is a fastening element for the cuff.

- Base for the hatch cover.

- Glass part of the hatch window.

- This is a decorative outer hatch panel.

- Mounting pins that fix the position of the hatch.

- A handle that can be used to close the hatch through which laundry is loaded.

- The mechanism that ensures the operation of the device that locks the hatch. If it malfunctions, it will be impossible to lock the hatch in the closed position.

- Bushings that hold the hatch.

- Front wall of the washing machine.

- Fastening elements for holding the front panel.

- A device designed to lock a hatch.

- Upper spacer bar.

- Bottom spacer bar.

- Latches that are designed to secure the top panel of the Bosch washing machine.

Tank, drum and electrics

The main working parts of any such machine are the tank and the drum, as well as the electrics, which will ensure the operation of the washing machine in various modes. Bosch devices use the following parts:

- A bolt that is designed to secure the drum pulley.

- The large pulley for the drum is designed to transmit the rotation from the electric motor to the drum.

- The back wall of the tank where laundry was loaded.

- Bearings that allow the drum to rotate.

- The drive belt connects the axle, which is rotated by the motor, and a pulley attached to the drum.

- A stopper that stops the drum.

- Metal drum together with a special cross with a bushing.

- Large rubber seal for the tank.

- Counterweight.

- The mechanism by which a counterweight is attached.

- Bolts that provide reliable fastening of the electric motor of the washing machine.

- Front engine mounts.

- An electric motor that rotates the tank.

- Electric motor brushes.

- Rear engine mounts.

- Stands for mounting the tank. They are designed for shock absorption, which dampens the rocking of the machine, which can occur due to the rapid rotation of the drum.

- A mechanism designed to fix the heating element.

- An element that heats water to the desired temperature.

- Thermistor is a temperature sensor, based on the data of which water heating is controlled.

- A clamp that is designed to secure the cuff.

- Rubber cuff of the hatch.

- Thin rubber gasket.

- Front counterweight-stabilizer.

- Front of the tank.

- Springs that are designed to hang the tank.

Hydraulic system

This system is used to ensure that water enters the washing machine and waste water is drained. In addition, one of the tasks of hydraulics is to ensure the flow of washing powder and stir it. It also provides direct washing and rinsing of laundry.

The hydraulic system includes the following parts:

- Twin water inlet valve.

- Tube for powder distributor.

- Cover for powder receptacle.

- A special mesh filter for the water entering the machine. It prevents dirt and small stones from getting into the tank.

- A hose through which water from the plumbing system flows into the washing machine.

- Flow-through mesh filter, which is located between the water supply and the inlet hose.

- A mount that is designed to hold the hose through which water is supplied to the machine.

- A straight pipe through which water enters the cuvette, where mixing with the powder occurs.

- A niche for the container, where the powder and water enter, are mixed and transferred to the tank.

- A cuvette where the powder is mixed with water.

- Drain pipe clamp.

- Large mixer pipe.

- Clamp for the drain pipe.

- A ball that acts as a float to prevent water from flowing out during washing.

- A hose through which waste water is drained after washing.

- Large drain pipe.

- Air adapter. Used to operate the pressure sensor.

- A large tube that is part of a pressure switch.

- Pressostat – a sensor that is designed to measure pressure.

- Drain pump. It consists of several parts. Ensures that water is drained from this device.

- A filter that traps debris which should have come out along with the waste water. It can trap loose buttons, contents left in the pockets of washed clothing, and other similar small items.

- Plastic pump housing.

- Rubber gasket.

- A long pipe through which water drains.

- Fasteners designed to fix the pipe.

- Fastening for fixing the outlet of the pipe.

Design Features

One of the important features of Bosch machines is that its design is carefully thought out. During the design, the accumulated experience was taken into account and everything was done to ensure that the machines operated reliably and did not present difficulties during repair. One example of such models is Bosch max 5.

There are no overly complex parts in the design. With only a Phillips screwdriver and wrenches of the required sizes, you can almost completely disassemble the washing machine.

Another feature of devices of this brand is a durable hatch through which laundry is loaded. This chrome sunroof has double glass. It is almost impossible to accidentally damage it.

Conclusion

This brand is different not only quality and reliability, but also ease of disassembly. Knowing well the structure of the washing machine, you can confidently undertake repairs yourself.