Choosing an automatic washing machine - this is a responsible matter, but it is equally important to correctly connect it to the internal communications. Particular attention should be paid to the electrical part. You need to choose a reliable socket, install it correctly, select the correct wire cross-section for the washing machine and perform the installation efficiently. Most often, wiring is done during a major renovation of an apartment, but if necessary, you can lay a new cable immediately before installing new household appliances.

Choosing an automatic washing machine - this is a responsible matter, but it is equally important to correctly connect it to the internal communications. Particular attention should be paid to the electrical part. You need to choose a reliable socket, install it correctly, select the correct wire cross-section for the washing machine and perform the installation efficiently. Most often, wiring is done during a major renovation of an apartment, but if necessary, you can lay a new cable immediately before installing new household appliances.

Features of connecting the washing machine to the electrical network

Like any other electrical appliance, a washing machine consumes electricity. Moreover, it belongs to the class of high-power consumers, as a result of which connection must be made strictly compliance with a number of rules.

It is strictly forbidden to connect the washing machine:

- to a socket with visible damage;

- to electrical wiring made with a cable of insufficient cross-section;

- through extension cords or adapters;

- using a tee to a socket with a high-power electrical appliance already connected.

To protect the washing machine from possible breakdown, and yourself from a serious accident, you should select a separate outlet for connection, designed to operate in conditions of high humidity. The connection should be made using a large cross-section wire, and it should not come out of the nearest junction box, but directly from the panel. Otherwise, when the engine is turned on at maximum speed, the wire insulation may melt, which in turn can cause a fire.

Selecting a wire to connect a washing machine

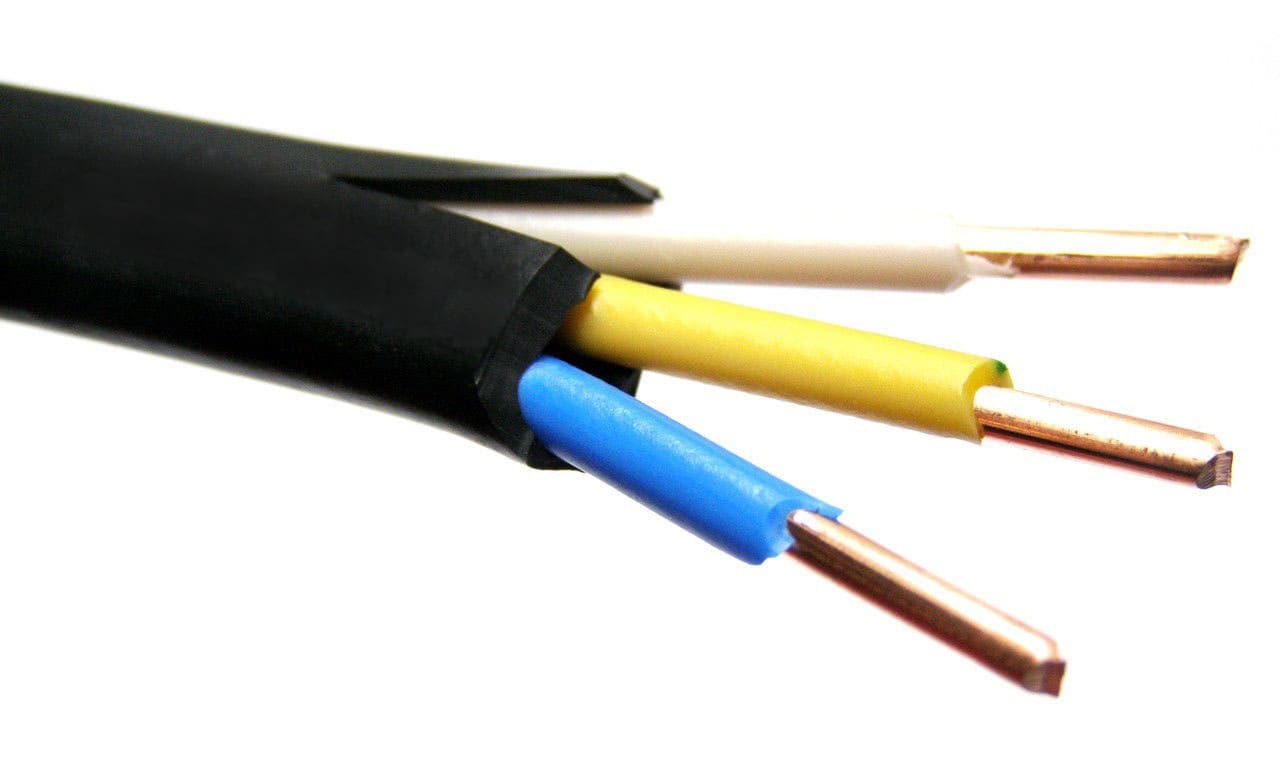

The reliability and durability of electrical wiring directly depends on the quality of its components. First of all, this applies to the wire. The main criteria for its selection are as follows:

- number of cores;

- conductor material;

- cross-section of the current-carrying conductor.

According to technical regulations, a modern automatic washing machine must be grounded. To do this, it is equipped with a plug with special contacts, therefore, you will need a three-core wire and a corresponding socket.

Aluminum and copper wire are available for sale. It is not recommended to use aluminum to power large household appliances; the optimal choice is copper.

Additional wiring accessories

Having decided on the wire parameters, you can move on to auxiliary devices, without which it is impossible to ensure connecting a washing machine. Required:

- powerful socket;

- socket box with fasteners;

- terminals for connecting wires;

- residual current device (automatic);

- cable channel (in case of open installation).

Particular attention should be paid to the choice of outlet. First of all, it must be designed for a power exceeding the consumption of the washing machine, otherwise the material may melt, contact deterioration, failure, and possibly a fire. We also must not forget that the washing machine is usually installed in the bathroom; it is operated in conditions of high humidity, therefore, the outlet must be waterproof.

Other parts must be selected based on their quality. Even something as simple at first glance as a socket box significantly affects the durability and reliability of the wiring. There is no need to buy cheap plastic products; if heated, they will become a source of pungent odor when the temperature rises strongly may catch fire. The same applies to the cable channel.

DIY wiring for a washing machine

Even if a major renovation of the bathroom is not planned, but purchased new automatic washing machine, it is worth laying a new cable to the place of its planned installation, the cross-section and other parameters of which meet all standards and requirements. Of course, you can invite specialists to do this work, but if you have some skills, it’s easy to do it yourself.

Planning and marking

Before you get down to business, you need to choose the optimal location to install the outlet. It should be located in close proximity to the machine, but the distance to the shield must also be taken into account. Do not forget that the further the shield is, the more wire will be required, in addition, the more work on gating and subsequent sealing of the channel will have to be done.

The installation location of the socket, as well as the wire route, is marked with a marker directly on the wall. When planning a route, you must remember that the wire must run either strictly vertically or strictly horizontally. Violation of this rule can cause an accident; not knowing where the wiring is laid, you can drive a nail or tighten a screw extremely unsuccessfully.

Having finished marking, it is worth checking everything again, and at the same time making sure that there is a sufficient amount of wire and its cross-section is correctly selected. It is important to understand here that high-quality wiring for a washing machine is continuous wiring. There should be no connections or twists in the channel - these are potential fire points.

Tools and consumables

The list of tools that will be required to lay the wire to the washing machine is individual and directly depends on the material of the walls. In limestone or a thick layer of plaster, you can chisel a channel with a “classic” hammer and chisel; in the case of monolithic reinforced concrete, you cannot do without a grinder. In general, you should prepare the following for work:

- electric drill and concrete drills;

- grinder with a disc for stone;

- sharp mounting knife;

- wire cutters and pliers;

- several screwdrivers;

- indicator screwdriver.

Mounting space for socket and groove

It is better to start chiseling from the recess for the socket. The optimal tool for this seems to be an electric drill with an attachment for drilling cylindrical holes. It is only important to choose a crown of a suitable diameter, focusing on the parameters of the socket box. If there is no such attachment, you can drill holes over the entire area of the future recess and carefully knock down the jumpers with a chisel. The recess will not be as neat, but the method is quite effective.

Next they move on to gating. Ideally, you can use a special tool for this – a wall chaser. It leaves behind a perfectly even groove; working with it does not require excessive physical effort. In the absence of one, you can get by with the same drill.Holes are drilled along the cable laying line with the smallest possible pitch, and the final formation of the groove is done using a grinder.

Sometimes you can do without dusty work at all; a cable laying channel will help out. It is enough to fix the box on the wall and lay the wire of the required cross-section inside it. It's quick and easy, but not always aesthetically acceptable.

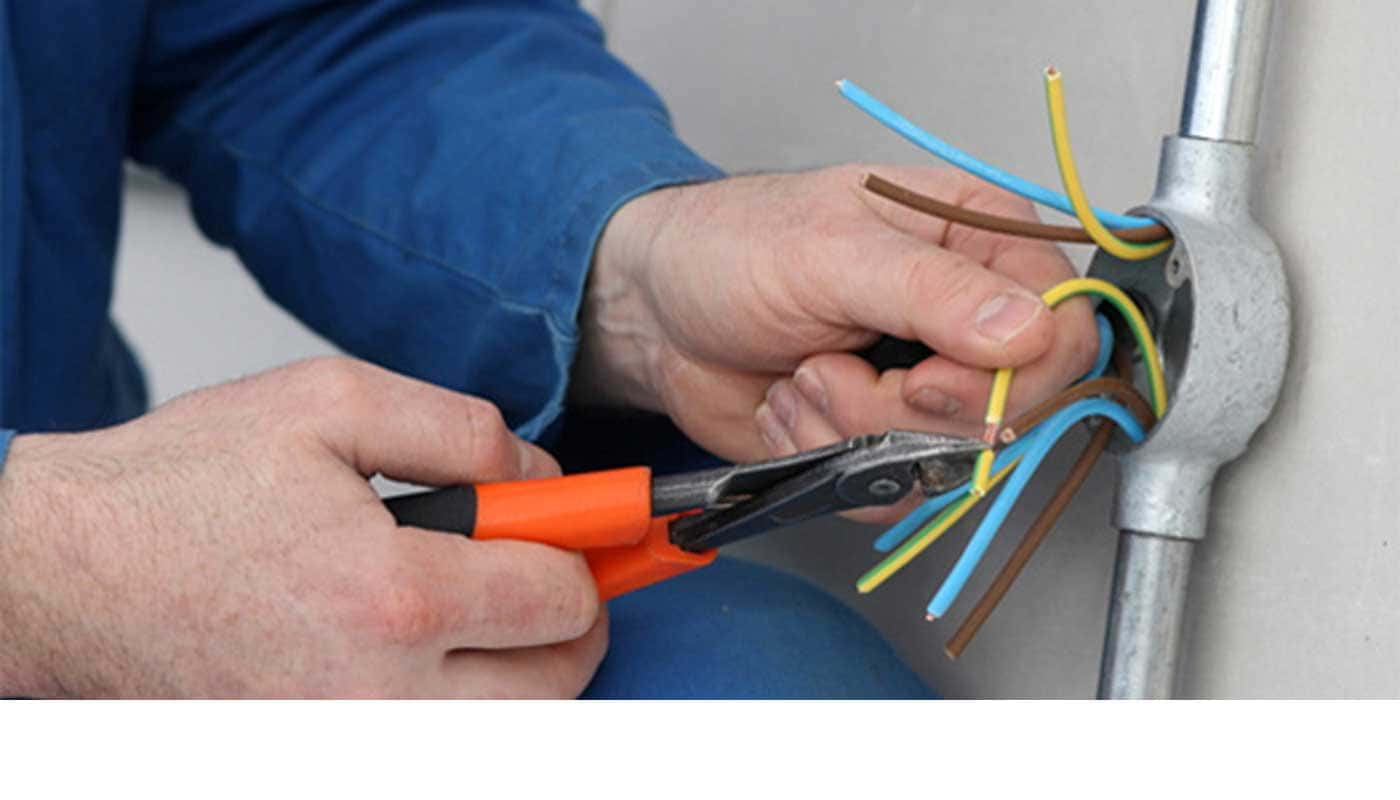

Wire laying work

They start pulling the wiring from the panel. At the same time, it is important not to forget that an additional machine will be installed in it. Before starting installation, you need to mark the connection points of the conductors (phase, neutral, grounding), but you do not need to connect the terminals yet.

Installing an outlet

After the wiring is laid along its entire length, you can install the socket. The sequence of actions is as follows.

- Installation of a socket box. To fix it, use the complete fasteners, but it wouldn’t hurt to additionally “seat” it with cold welding or sealant.

- The ends of the wire are inserted into the hole in the socket box.

- Unpack the socket and take out its inner part.

- The terminals are connected alternately: phase, neutral, ground. At the same time, you need to make sure that the ends of the wire are not too tight; do not forget that it is quite possible that the socket will have to be repaired.

- Using standard fasteners, the socket is securely fixed in the socket box. No play is allowed; it must “sit” motionless.

- Screw on the plastic cover.

Checking the quality of work

You can verify that the installation has been completed correctly using a test screwdriver; it can be successfully replaced by any household appliance powered by the mains, for example, a table lamp. If everything is fine, you can seal the channel and move on to finishing the walls.

Good wiring is a guarantee safe operation of any household appliances: refrigerator, water heater, dishwasher and a washing machine. Although laying wires and installing sockets is a rather complicated process, if you wish, you can do everything yourself. Of course, we must not forget that electricity is dangerous; if you have doubts about your own abilities, you should entrust the work to a master.