Washing machines are one of the most important appliances for a modern home. Therefore, every home master should know the main features and requirements in this area. Connecting your washing machine to the power supply yourself will save you a lot of money.

Washing machines are one of the most important appliances for a modern home. Therefore, every home master should know the main features and requirements in this area. Connecting your washing machine to the power supply yourself will save you a lot of money.

Cable brands, power ratings and cross-sections

Modern washing machines consume a lot of power, but manufacturers are trying to reduce this figure as much as possible. The average consumption level reaches 2500 W.

In practice, it is prohibited to use wires for which the following designations are used:

- PUNP.

- APUNP.

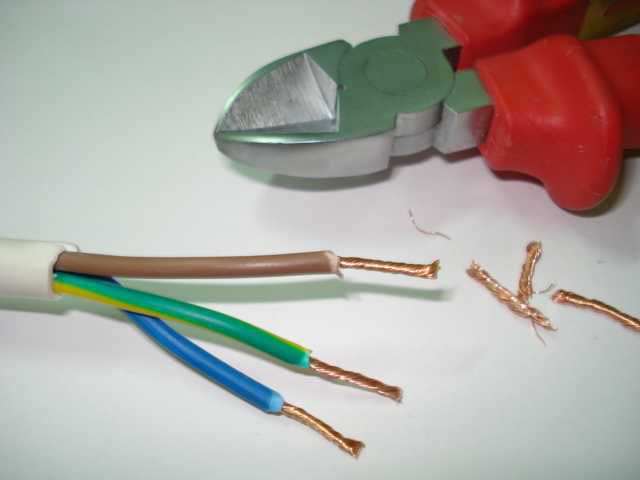

If the apartment is equipped only with old two-wire wiring, it is replaced with a three-wire analogue.

The copper three-wire type of wiring is most suitable for making connections.The use of protective additional devices is a mandatory requirement; such connection rules apply under any circumstances.

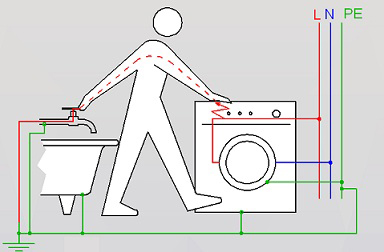

Grounding: let's start installation

Connecting to the electrical network is basically impossible without using grounding. This is also due to the fact that such devices are usually located in the bathroom. Such places are especially dangerous for electrical appliances.

Many manufacturers have begun to produce products that are grounded initially. In this case, the plug is equipped with a hole for the grounding contact.

Connect to an outlet

The socket must be waterproof if it is involved in the connection. Both the plug and the socket must meet modern requirements in this area. Connection diagrams are easy to find on specialized portals.

Washing machines: use the correct RCDs

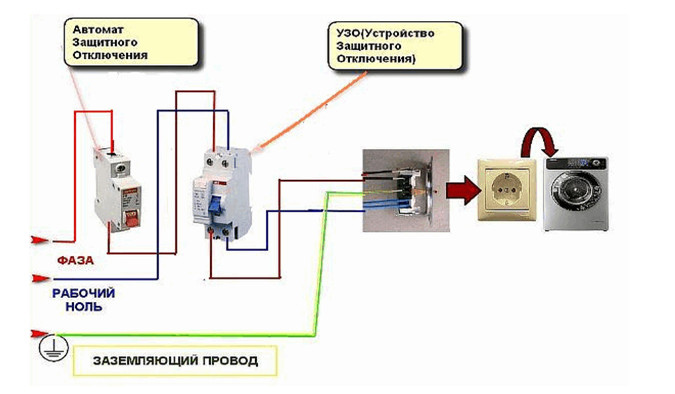

The washing machine must be protected if it is installed in the bathroom. Then you cannot do without automatic switches along with RCDs.

These devices will make operation as safe as possible for each family member. The device will simply be disconnected from the current supply when a breakdown occurs.

Carrying out electrical communications for washing machines

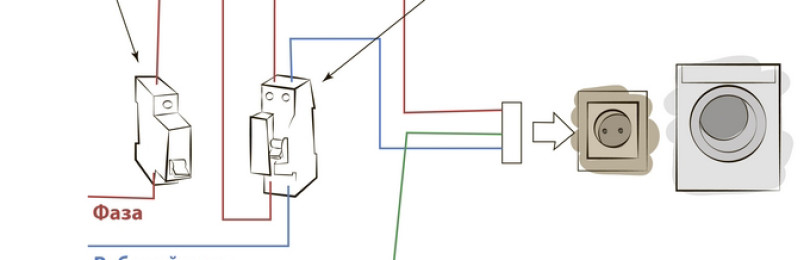

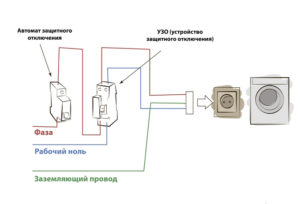

Let's consider existing high-quality solutions for this problem.The first thing to do is to run a separate cable with the appropriate cross-section directly from the distribution board. The circuit also includes a circuit breaker and grounding, an emergency shutdown device.

The option when they are connected to an outlet for an electric stove is quite acceptable. Its indicators should be sufficient to cope with the current loads. The three-core wire is removed from the outlet.

As the standard connection diagram says, work continues with the following components:

- Machine.

- Emergency shutdown device.

- Ground wire.

The three cores of this wire should then converge inside one Euro socket. It would be good if it had a ceramic base. The main thing is that you can connect the ground wire yourself.

Such solutions have their advantages:

- Attractive appearance.

- Less chance of wires coming into contact with moisture.

If you use the machine correctly, equipped with an emergency shutdown system, then the classic circuit can be simplified. But there are not very many really high-quality machines being produced on our market yet.

Particular attention is paid to the outlet to which the washing machine is directly connected. The main thing is to choose high-quality products that provide maximum protection. At the next stage there is a connection to the water supply and sewerage system.

We provide protection against failures

High-quality grounding is the first step towards forgetting about most problems. But only recently have people started thinking about proper grounding for sockets that are supplied with devices.

The actions are described as follows:

- We bring out a wire that is intended for grounding to the desired wall of the house. The end of the wire should reach the foundation.

- A piece of reinforcement is driven into the ground to a depth of about 2 meters. The tip should stick out on the surface, about 30 centimeters.

- The ends of the wire must be completely stripped of insulation. The protruding ends must be freed from dirt and rust. The exposed part of the wire must be tightly wrapped around the reinforcement. The connection can be fastened with a small amount of cold welding to make everything more reliable.

- The place where the reinforcement and the wire are connected is well wrapped with electrical tape. A piece of rubber hose with the appropriate diameter is placed on top of the reinforcement.

- This completes the preparation of proper grounding. Now the wire and socket are connected without problems.

Additional advice from experts

Connecting a washing machine to all utilities is a problem with many solutions. But not all of them are correct. Some, on the contrary, only accelerate the process of natural wear. Moreover, they negatively affect the health of the owners.

- Therefore, it is worth considering the following nuances when carrying out work:

- Grounding contacts should never be connected to batteries or gas or water supply lines.

- You can use not only classic fum tape, but also similar materials such as flax and paste. They cope with blocking leaks no less effectively.

- Washing machines can be connected not only to the central water supply.High-quality grounding is the first step towards forgetting about most problems. But only recently have people begun to think about proper grounding for sockets that are supplied with devices.

The actions are described as follows:

We bring out a wire that is intended for grounding to the desired wall of the house. The end of the wire should reach the foundation.

A piece of reinforcement is driven into the ground to a depth of approximately 2 meters. The tip should stick out on the surface, about 30 centimeters.

The ends of the wire must be completely free of insulation. Protruding ends need to be removed from dirt and rust. The exposed part of the wire must be tightly wrapped around the fittings. The connection can be secured with a small amount of cold welding to make everything more secure.