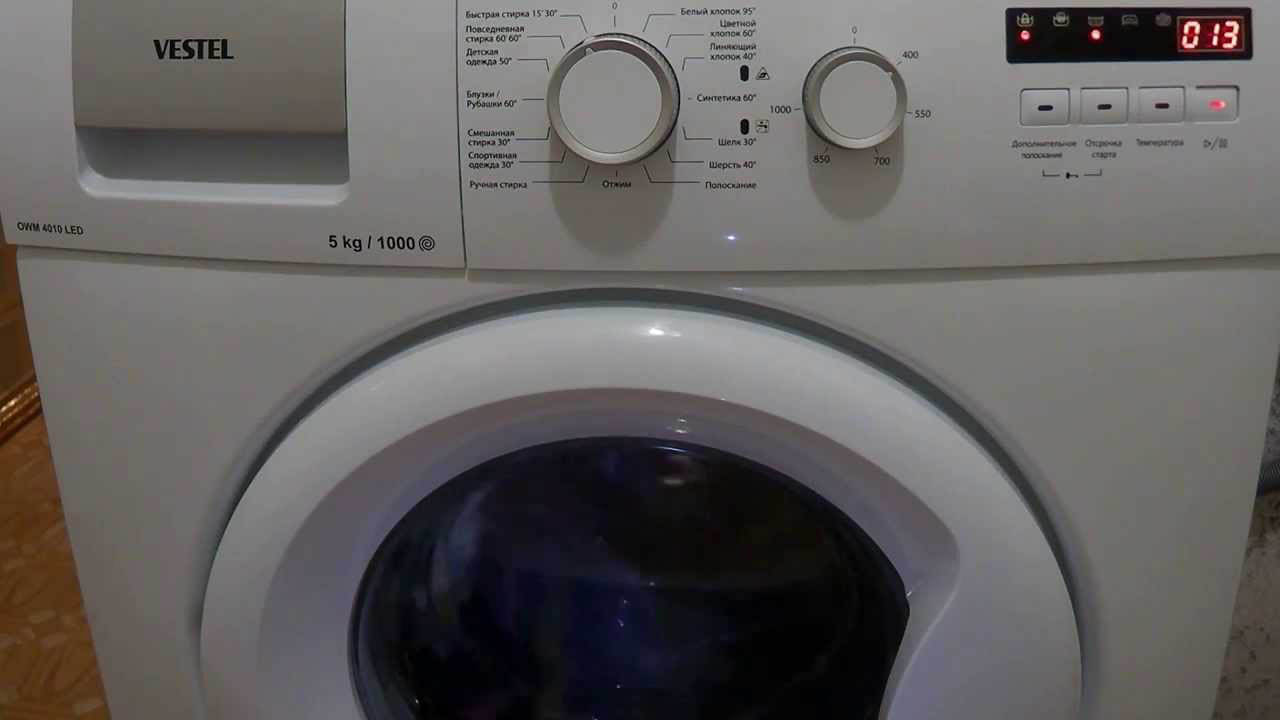

Vestel washing machines have long been among the most popular devices of this class present on the domestic market. This model has been known on the household appliances market since 2006. Of course, like many other washing machines, breakdowns occur from time to time in this modification. Compared to analogues from other manufacturers, they occur much less frequently. You will learn how to repair a Vestel washing machine yourself from this article.

The most common faults

If we consider the situation of a malfunction of a Vestel washing machine from a theoretical perspective, it is worth noting that a breakdown can occur for a variety of reasons. For example, this could be exploitation using an incorrect algorithm. Characteristic manifestations of this type can also be low-quality components used during the assembly process of the device.

The listed options are mostly situations of what is called a one-time nature. Professionals who repair washing machines at service centers note that each of the models is characterized by its own group of characteristic breakdowns, which almost always appear during use.

Therefore, washing machines from the Turkish manufacturer under the name Vestel are not an exception to this statistics.

Let us list the most typical malfunctions of this model of the device.

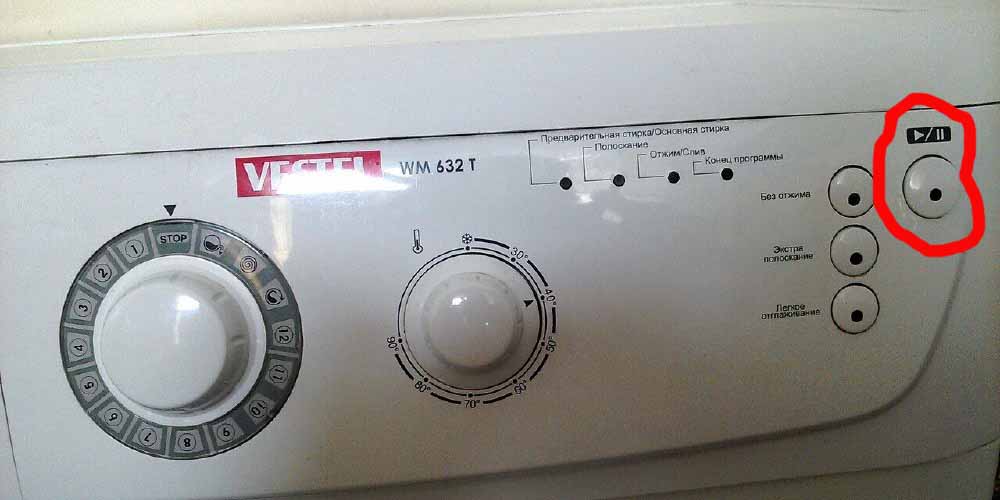

- First of all, the washing mode does not start, even when the control panel is in the on state and the unit itself is functioning properly. In this case, the corresponding program is selected, but the start button does not respond properly to the user's pressing.

- A possible option for this unit to hang up immediately after the washing procedure begins. In this situation, it is even possible to select a program for operation and then start it. Then, after a short-term operation for 5 to 10 minutes, it interrupts the process and then does not respond to any commands. In half of such situations, users can see the error code E07 on the display.

- The unit does not collect washing powder and detergent from the so-called cuvette. This malfunction is quite common for new models of this manufacturer. The assumption that this may be a reaction to poor quality water or pollution in this case is erroneous.

This list of model faults is, of course, incomplete, since there are a number of other faults that can be listed additionally. At the same time, the listed options are the most common, and it makes sense to talk about them, since this can be fixed with your own hands if necessary, without resorting to a specialist for advice.

The machine does not start washing

Currently, the prevailing opinion among most users is that if the program for the washing mode does not start and there is no reaction from the corresponding button located on the control panel, then this refers specifically to electronics.

Basically, the situation looks much simpler than it seems to customers. According to statistics, in about 40 percent of all such situations, the sensor that is necessary to block the hatch breaks down. Therefore, the module that controls the unit thinks that the hatch is in an open state and, accordingly, does not allow the washing mode to start. It also does not display a message on the display that an error has occurred.

Thus, the hatch is in the closed position and the person presses the start button, but there is no reaction from the device with this action. Then, do-it-yourself repair of the Vestel washing machine can be done quite simply.

How should you proceed to find the cause of the malfunction?

- First of all, you need to turn off the machine and then wait 10 seconds. After that, you need to turn it on. If this situation repeats, you need to repeat the procedure. If this situation still occurs after this, then you need to move on to the next step of the algorithm.

- Now the device is disconnected from the power supply and the lid itself is opened. Next? using a Phillips-type screwdriver, a pair of screws located next to the locking device are unscrewed.

- Carefully remove the mechanism that locks the hatch of the washing machine.It is important to understand that you need to carefully perform the action so as not to tear off the wiring connected to the sensor.

- Now use a multimeter to measure the resistance value on the contacts of this sensor themselves. Its value in good condition when cold should be 900 Ohm. If the multimeter gives 0 or 1, the device that drives out the lock is faulty.

This is the main reason that leads to the program not starting. Then you need to replace this sensor and the situation will normalize. If the device is in good condition and a lock has occurred, then the problem should be looked for in the electronics. To do this, disassemble the panel itself and initially check the start button. Then sequentially check the microcircuit. In such a situation, it is advisable to resort to the help of a professional.

Freezing after the start of the washing process

If this faithful assistant of the housewife suddenly begins to freeze immediately after the start of the wash, then you need to carefully examine it. As noted, this manifestation most often occurs in the first 10 minutes of operation or in the last three minutes of this process. Then the machine hangs, as experts say, in a dead state and the drum itself no longer shows signs of work. At the same time, the control panel itself is in working order. All indications are functioning, and the display projects the operating mode of the program. Then the repair of the Vestel washing machine is carried out according to the user's algorithm.

At the same time, when there is no indication of the error type E07 on the display, it is necessary to carry out actions according to the following algorithm:

- It is necessary to turn off the machine by de-energizing it from the power outlet. This breaks the circuit.After waiting for half a minute, it is reconnected and the corresponding mode is started. Subsequently, the control board reboots and the machine operates normally.

- If the problem reoccurs, you must turn off the device again and check that it is correctly aligned using a building level. This problem often occurs with such systems if they are uneven, when the floor is curved and there is no additional reinforcement.

- The reason for the sagging may be the blocking of the hatch itself. We must try to push him a little. If there is a corresponding reaction and the device begins to execute the program, then perhaps the problem is in the blocking element. You just need to replace it. It should also be noted that in such a situation, an indirect sign is that jamming occurs during the opening of the hatch.

The most unfavorable option is to further repeat the freezing process and display error code E07 on the display. Then we can say with almost one hundred percent certainty that the problem is in the control board and you need to contact a technician who can diagnose and fix the machine’s breakdown. There is no need to carry out work in this situation yourself, as more expensive repairs may be needed later.

No powder or rinse aid is collected

A fairly common situation is when the unit starts washing without using washing powder at all. At the same time, the detergent was poured in sufficient quantity into the appropriate container. This situation in Vestel washing machines occurs mainly due to the fact that the water supply valve is faulty.

Quite often it is noted that this manufacturer’s water supply valves have factory defects. It is also interesting that this is a rather non-standard defect, which does not appear immediately after the model is put into use. It mainly begins to appear after the warranty period for the washing machine ends.

After starting the washing program, the control module commands this valve to supply water. In a standard situation, it opens and water flows into the tank. Then it closes and the washing begins.

In this type of situation it opens, but not completely. Therefore, water will flow for a longer time. In this case, the pressure will be lower than in normal mode. Thus, it does not fall into the cuvette itself, where there is already powder. Then the powder is not used and, accordingly, the quality of the washing performed is quite low.

Its repair is carried out by replacement.

- You need to buy a new component for a washing machine of the appropriate type.

- Then disconnect it from the power supply.

- Unscrew the screws that secure the cover on top and remove it.

- Further under it, where the inlet hose is, there is a valve made of plastic.

- It is disconnected from the sensor and the valve is removed from the mount.

- Now a new valve is installed in this place.

- Then all actions are performed in reverse order.

This washing machine is of middle class quality and rightfully belongs to the budget option, which will work properly throughout the entire warranty period.

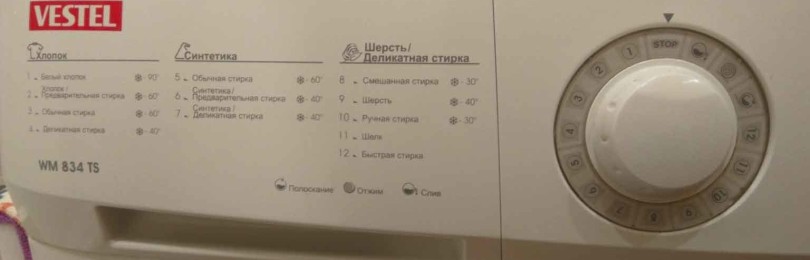

Hello. Please tell me the machine is vestel wm 834 t. Fills with water, spins the drum for 30 seconds, stops and drains the water. This completes the washing process. I will be very grateful for your answer.

If the washing machine fills with water and then drains it without completing the wash, there may be several reasons. You can read more about this on this page of the site. https://washer.tomathouse.com/en/remont/stiralnaya-mashina-zalivaet-i-slivaet-vodu.html