Brandt washing equipment works comfortably and reliably, however, since it has been in use for many years, breakdowns may occur sooner or later. If this happens, it is not always necessary to call a specialist. In some cases, you can repair Brandt washing machines yourself.

Brandt washing equipment works comfortably and reliably, however, since it has been in use for many years, breakdowns may occur sooner or later. If this happens, it is not always necessary to call a specialist. In some cases, you can repair Brandt washing machines yourself.

Review

No matter how reliable household appliances are, with prolonged use some components may break down. washing mashines have been sold in Russia for more than 20 years, and during this time service workshops have accumulated statistical data on what breakdowns occur most often. In the Russian Federation, budget-level models are in greatest demand. The quality of their parts and assembly is not as high as that of elite models. As a result, breakdowns are much more common.

The list of the most common breakdowns in most cases contains the same items.

- Failures related to the drain pump occur relatively often. If we consider branded machines with vertical loading, then quite often the pump needs to be repaired. The frequency of such breakdowns is usually two or three years.

- Blockages occur quite often in almost any model of washing machine.They are connected not only with the fact that sometimes some things are forgotten in clothes intended for washing. This is also significantly affected by the purity of the water supplied to the machine.

- In almost any Brandt washing machine, one of the most vulnerable components is the temperature sensor. Failure can occur quite early, only three years after the start of operation.

- Here we need to mention the heating element - the heating element of the washing machine. It works under heavy load and is one of the most vulnerable points of the machine. A breakdown can occur at almost any time, for example, a year after the start of operation.

If there is a malfunction, an error code is displayed on the electronic display.

It should be taken into account that the main parts of branded washing mashines are reliable and rarely break down.

Often the question of repair first arises no earlier than seven or ten years of operation have passed. Although this indicates the high reliability of these household appliances, a serious problem arises. The fact is that dealers bringing spare parts for Brandt washing mashines from Europe to Russia focus on those products that are the most popular on the market. This does not include parts for washing machines manufactured ten or more years ago.

As for current models, units are imported for which consumers have the highest demand.

Here is a list of such spare parts:

- heating elements;

- covers;

- drive belts;

- top covers;

- pipes;

- pulleys;

- rubber rings and gaskets;

- activators;

- pumps;

- drum flaps;

- shock absorbers.

Display or control modules are considered the most accessible on the spare parts market.It should be borne in mind that they are not commercially available for all models of branded washing machines. In some cases, finding them is quite difficult. If you had to face this situation, you will have to order these units directly abroad. However, the price will be relatively high.

You can purchase spare parts not only in Europe, but also by placing an order in China. However, although the price will be slightly lower, the quality will not be as high as the original parts.

If the consumer is faced with the need for repairs, it is necessary first to assess its cost. In some cases it may be too high. It is possible that repairs will cost more than the entire washing mashine purchased many years ago.

The most common faults

The most common breakdowns will be discussed next. To eliminate them, it is not always necessary to call a specialist. In some cases, the situation can be corrected on your own. It will be explained in detail what needs to be done for this.

If there is a blockage

Many people believe that this is the scourge of washing machines. However, you can handle this on your own. With proper operation and proper correction of what happened, no problems should arise. As you know, some machine models use vertical loading, while others use horizontal loading. Their drainage is located differently, but this does not create problems. First, let's look at what needs to be done in horizontal loading machines. There are two options here:

- The drain hole needs cleaning.

- The pipes need to be cleaned.

In the first case, we open the washing machine and see approximately the following picture:

- First you need to unscrew one of the drum flaps.The other one needs to be left in place.

- We unfold this drum and then open the doors, behind which we see a drain hole.

- Let's clean it.

After doing this, the problem will most likely be fixed.

On top-loading machines, the drain hole is at the bottom and is easy to see.

In some cases, the blockage remains. This means that the pipes still need to be cleaned. They are quite wide, but this does not exclude the possibility of clogging.

To do this, we do this.

- Remove the back wall of the washing machine.

- Next, you need to use a screwdriver and loosen the clamps a little.

- Now drain the water.

- Next you need to remove the pipes and clean them.

- Afterwards they are installed back.

It is advisable to do such cleaning not only when a problem occurs. If done periodically every two or three months, this will be an effective preventive measure to combat blockages.

Repair of inlet valve filters

Unfortunately, the creators of Brandt washing machines created their equipment, assuming that it would use only purified water. Therefore, inlet filters are designed mainly for such water. However, given that in various cases the incoming water can have not only a high degree of purity, but also a very low one, there are often cases when these filters become clogged. If this happens, they need to be cleaned.

It's not difficult to do this yourself.

- First, the water flowing into the machine is interrupted.

- Now you need to disconnect the inlet hose.

- Next you will need pliers. With their help, remove the inlet filter and carefully clean it.

- Then the filter must be inserted into place.

Although this filter may become dirty periodically and will need to be cleaned each time, it is not recommended to remove it.In this case, water will flow into the machine of the same quality as flows through the pipes. This risks contaminated water getting into the washing mashine.

If there are problems with water heating

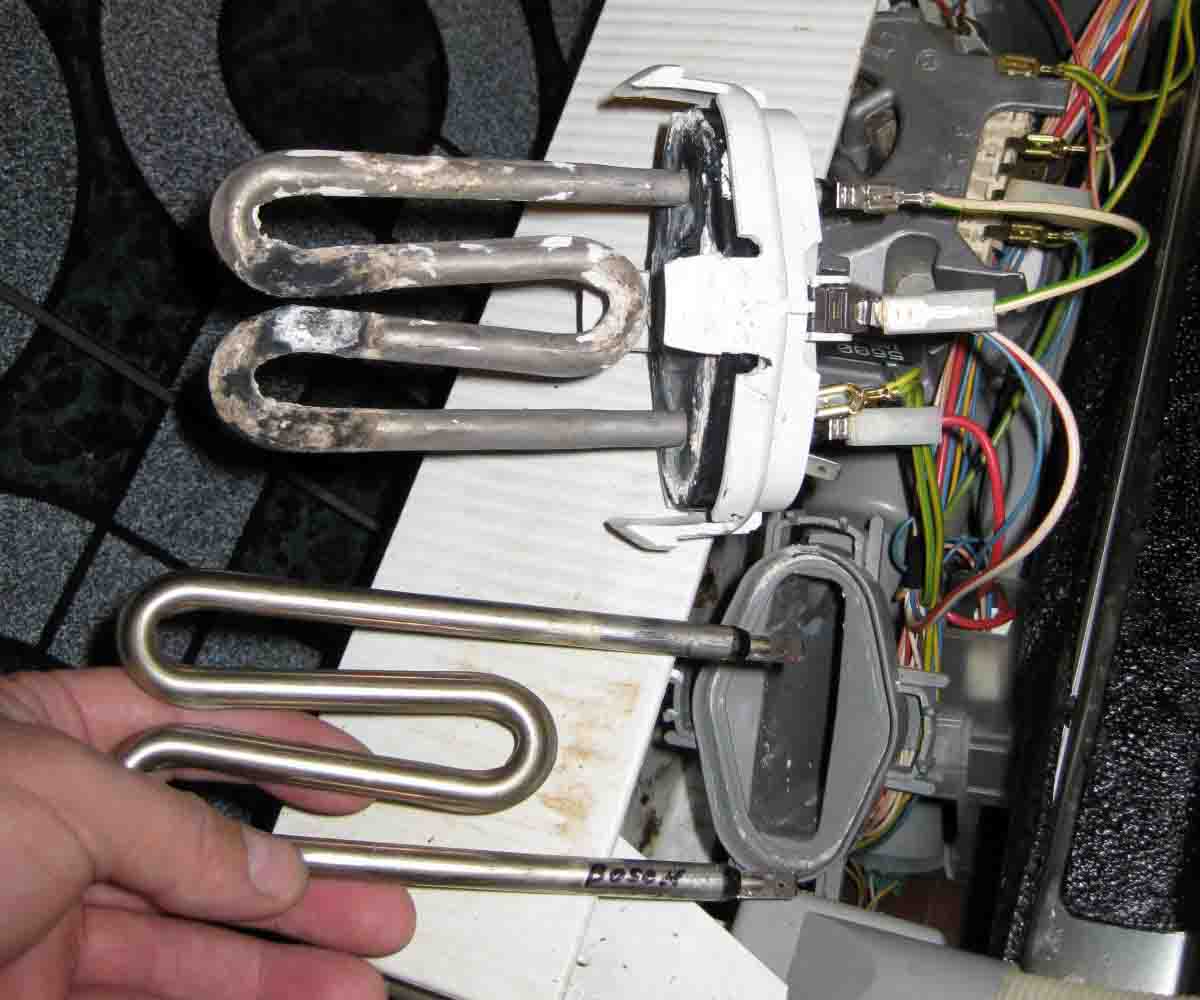

If the heating of the water stops during washing, or vice versa, the water is hotter than necessary, you need to inspect the heating element (heating element) and temperature sensor. We'll show you. How to do this in washing machines that use top loading.

You can do this yourself as follows.

- First, unscrew the back wall of the washing machine. We will see a motor, a rubber pulley, and a tank wall. In the upper part there is a plug behind which the components we need are installed: a heating element and a temperature sensor.

- We take out the plug and remove them, having first disconnected the wires.

- First you need to measure the resistance value at the contacts of the temperature sensor. If they are normal, the sensor is working. Now all that remains is to remove the old heating element and install a new one, first placing it in a rubber case and then inserting it into the machine under the plug. We connect the wires.

- We install the back wall in place.

It is important to remember that only the original heating element must be installed, specifically for this particular model of washing machine. It is not recommended to use a similar unit, as this may lead to equipment failure. If such a part is not available, you need to order it and wait for delivery.

Faulty drain pump

This part is usually available for all major Brandt washing machines. This unit is relatively expensive, so it makes sense to make sure that it is in fact faulty and needs to be replaced.

This is done in this order.

- Start by cleaning the pipe. In addition, it is also recommended to clean the drain hose.

- To get to the desired node, you will first have to remove the back wall.

- Before starting work, you must disconnect the wires. In order to later connect them in the correct order, they must be carefully marked.

- Now let's check the resistance using a multimeter.

- The pump is secured with special bolts that need to be unscrewed.

- Remove the completely disconnected pump from the washing machine.

- Now you need to take the impeller and twist it slightly. If it is faulty, it will be difficult to give in.

- If the drain pump needs to be replaced, insert it into place by performing the above operations in reverse order.

When inspecting the drain pump, you need to pay attention to the bushing. Debris may accumulate there, which may cause poor performance. If cleaning is done, the pump does not need to be replaced. But such a conclusion can be made only if the values shown by the multimeter correspond to the norm.

Operation of the electronic control module

It may be that a specific fault could not be found, but the machine still does not work. In this case, there is a high probability that the electronics that perform control functions in the washing machine are faulty. In this case, it is not recommended to troubleshoot Brandt washing machines yourself. It is important not only to know how to carry out repair work correctly, but also to have the necessary experience. In this situation, it would be wisest to contact a specialist.

Conclusion

Although Brandt washing machines are of high quality and reliable, this does not exclude the fact that in many cases you can repair them yourself without paying to call a specialist for expensive repairs. In this case, it may be necessary, as a last resort, to buy a new unit to replace the faulty one.For successful repairs, it is enough to follow the relevant instructions exactly. Proper operation of the washing machine can further extend its service life and reduce the likelihood of breakdowns.