Electricity is used to power many household appliances, including washing machines. Without this type of energy it is impossible to imagine the normal functioning of modern housing. Using electrical equipment requires following certain rules, otherwise ignoring them can lead to a lot of trouble, both financially and health-related.

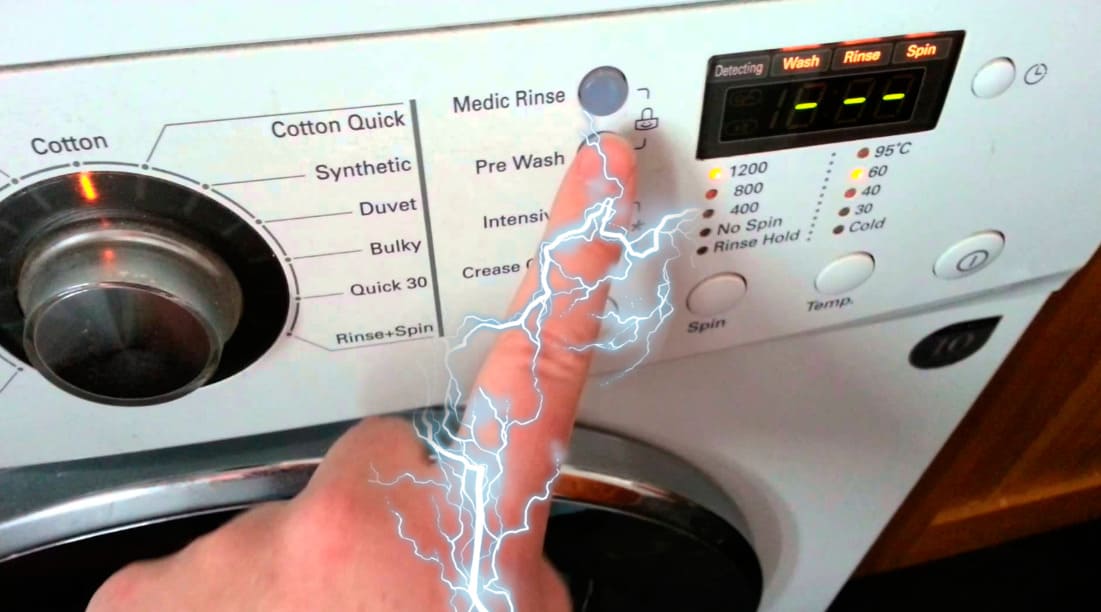

The washing machine is an episodic unit. It can be located in a designated place without attracting attention until the need for its use arises. But sometimes a situation may arise when the washing machine shocks. It is important not to panic, but to try to find out the original source of this phenomenon. It is quite possible that the reasons lie in minor defects, and eliminating them is quite possible.

Turn off the power to the equipment

Typically, many users have their washing machine plug constantly plugged into the mains.If there are leaks in the electrical network, then when you touch the washing unit, characteristic vibrations are felt. More serious leaks are felt when:

- walking barefoot on a wet bathroom floor;

- flow of water when opening the tap;

- contact with water pressure fittings.

This is due to the ability of current to penetrate objects with good conductivity. In this case, the washing machine forms a link in the overall chain, even without being in operation. The leakage current of natural origin can be felt as a tingling sensation. A significant leak can cause shock, a sharp blow, or a burn.

To avoid physical damage, you should move away from the device and take a number of measures. First, for safety reasons, it must be de-energized by turning off the general electricity in the apartment or turning off a separate circuit breaker. After de-energizing the machine, you can apply voltage to the remaining consumers. To avoid further electrical injuries, you should determine the causes of the malfunction.

Reasons why the washing machine gives an electric shock

Some of the current is not used for its intended purpose, but goes into losses. Natural leakage occurs in all electrical appliances. Its presence is associated with imperfect insulation. Its value is so small (up to 10 mA) that it can be neglected. Other leaks are associated with improper commissioning and resulting damage that can pose a danger to humans. When touching the source of a leak, the human body acts as a conductor of current, experiencing all its delights.

The washing machine is a multifunctional device in which electricity is distributed in several directions. Main modes of use:

- drum rotation;

- heating water;

- ensuring the operation of electronics.

Therefore, there are plenty of places for possible current leaks. Such measures as using a water pipe as a ground, turning the plug upside down, installing a rubber mat on the floor, do not eliminate the problem with current leaks.

No grounding

One of the requirements of the electrical safety regulations states that the connected equipment must be supplied with grounding. The third wire in the socket serves this purpose. This conductor is then connected to the grounding bus. Its purpose is to drain electricity from the body of the washing machine if a leak occurs. Grounding will not provide an understanding of the location of the leak, but it will prevent various electric shocks.

Internal wiring is damaged

When the internal wiring is broken, part of the voltage is supplied to the body of the machine. The cause of the violation of the integrity of the wires can be natural wear, overheating and the activity of small rodents. Poor contacts in the socket unit transmit electrical potential to the body. According to modern requirements, copper wiring with a cross-section of 2.5 sq. mm is required. The solution is to ring the internal network and replace damaged wires.

Breakdown of the washing machine motor winding

The motor can be the cause of an electric shock. A voltage shock when removing laundry from the drum signals problems with the insulating properties of the electric motor. Under intensive operating conditions, the motor windings heat up. Heating leads to melting of the varnish and loss of insulating properties.

As a result, the resistance of the turns decreases, which causes increased current consumption. As a result, an excessive amount of heat is released.ensuring the operation of electronics.

Consequently, there are plenty of places for possible current leaks. Measures such as using a water pipe as a ground, turning the plug upside down, or installing a rubber mat on the floor do not eliminate the problem of current leakage.

No grounding

One of the requirements of the electrical safety rules states that the connected equipment must be equipped with grounding. The third wire in the socket serves this purpose. This conductor is then connected to the ground bus. Its purpose is to drain electricity from the washing machine body if a leak occurs. Grounding will not provide an understanding of the location of the leak, but it will prevent various types of electric shock.

Internal wiring is damaged

When the internal wiring is broken, part of the voltage flows to the machine body. The reason for the violation of the integrity of the wires may be natural wear, overheating and the activity of small rodents. Poor quality contacts in the socket unit transmit electrical potential to the housing.

According to modern requirements, wiring is required to be copper with a cross-section of 2.5 square meters. mm. The solution seems to be dialing the internal network and replacing damaged wires.

Breakdown of the washing machine motor winding

The motor may be the cause of the electric shock. A voltage shock when removing laundry from the drum indicates problems with the insulating properties of the electric motor. Under intense operating conditions, the motor windings heat up. Heating causes the varnish to melt and lose its insulating properties.

As a result, the resistance of the turns decreases, which causes increased current consumption. As a result, an excess amount of heat is released.With the onset of a critical value, breakdowns occur on the engine with further transfer of impulse to the body. Serviceability analysis is carried out by measuring the resistance of the windings and the body.

Breakdown of the heating element housing

The most common reason is the emergency condition of the heating element. Symptoms, in addition to unsatisfactory water heating, appear in electric shock only during washing. This occurs due to a violation of the integrity of the shell and exposure of the thermal heating element. Another reason for depressurization of heating elements is unbalanced bearings. When rotating in critical phases, the drum touches the heating element, thereby deforming it.

A damaged heating element cannot be restored. It needs to be replaced.

Malfunction of the socket or wiring

Severe operating conditions are reflected in the condition of the electrical wiring. Damage to the insulation results in unauthorized leakage. This is indicated by electric shocks from a wet floor. In an apartment with a three-wire wiring, you should regularly check the integrity of the grounding conductor. The socket must have a connected real grounding conductor, and the device itself must belong to the class of Euro-sockets.

The electrical network in the bathroom is checked with a tester after first disconnecting the input circuit breaker.

The power button is faulty

This element is used most often, which leads to mechanical damage and wear of the structure. Due to humidity, the contacts of the “Start” button oxidize. This is a direct path to a short to surrounding metal with possible leakage to the housing. If the power button begins to act up, then the installed protection should knock out, right down to the plugs on the panel.

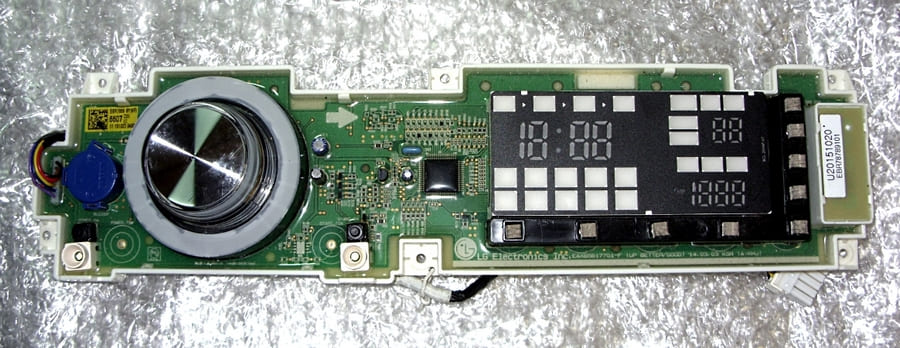

The control unit has failed

The logistic control board is complex in design. It contains many radio components and tracks, including a grounding circuit. The control unit is isolated from the case with a dielectric. Moisture on the board leads to electrolysis of the circuit and redirection of current flow. If you suspect a failure of the electronic control center, you should open access to the control unit, remove it, clean it and wash it with an alcohol-gasoline mixture. After thorough drying, carefully install it in place, paying attention to the condition of the contacts.

High humidity

This factor can cause a malfunction of the network filter. The problem lies in the features of its design. In the filter, the contacts are located at a small distance from each other. If cleaning is not done in a timely manner, dirt accumulates between them, which subsequently absorbs evaporating moisture. This provokes a short circuit. Another consequence is a breakdown on the case. Humidity also contributes to the appearance of oxide on the connections. Complications are solved by removing condensate and cleaning the contacts. The peculiarity of the leak is that when the contacts dry out, the current leakage disappears. Therefore, maintaining the internal microclimate in a dry state is important for the normal operation of the network filter and the machine as a whole.

It is necessary to change the operating conditions in the room. This is achieved by an effective ventilation mode. If it is not possible to completely or partially remove excess moisture, you should purchase a washing machine with a high moisture protection class.

What to do if the washing machine starts to shock?

The correct operation of any washing machine depends on the careful attitude of the owners.The logistics control board is complex in design. It contains many radio components and tracks, among which there is a ground loop. The control unit is isolated from the housing by a dielectric. Moisture on the board leads to electrolysis of the circuit and redirection of current flow. If you suspect a failure of the electronic control center, you should open access to the control unit, remove it, clean it and wash it with an alcohol-gasoline mixture. Upon completion of thorough drying, carefully install it in place, paying attention to the condition of the contacts.

High humidity

This factor may disrupt the operation of the network filter. The problem lies in the features of its design. In the filter, the contacts are located at a short distance from each other. If cleaning is not done in a timely manner, dirt accumulates between them, which subsequently absorbs evaporating moisture. This causes a short circuit. Another consequence is a breakdown on the body. Humidity also contributes to the appearance of oxide on compounds. Complications can be resolved by removing condensate and cleaning contacts.

The peculiarity of leakage is that when the contacts dry out, the current leakage disappears. Therefore, maintaining the internal microclimate in a dry state is important for the normal operation of the surge protector and the machine as a whole.

The operating conditions in the room must be changed.This is achieved by effective ventilation mode. If it is not possible to completely or partially remove excess moisture, you should purchase a washing unit with a high moisture resistance class.

What to do if the washing machine starts to shock?

The correct operation of any washing machine depends on the careful attitude of its owners. Regular wiping of all accessible surfaces and drying the internal space by leaving the loading hatches open can extend the life of normal life. These measures will delay the period when current leakage to the housing becomes inevitable. Newly purchased devices only produce electric shock if they are not connected to the power supply correctly.

Due to increased humidity, elements and insulation wear out. In such difficult conditions, individual parts and assemblies cannot perform 100% of their functionality. You can determine the culprit of the leaks yourself. To do this, a conventional tester checks the parts one by one for compliance with the certified resistance values. If there is a deviation from the norm, a decision is made to repair or replace the damaged area. All work is carried out with the power turned off. After cleaning, it is recommended to treat the contacts with an anti-corrosion compound.

Methods for troubleshooting

The relevance of leaks lies in the possible consequences. These currents can cause significant damage to expensive equipment, given the presence of various electronics in its configuration.The consequence may be impressive sums for restoring the functionality. Basic measures will ensure the functionality of the device and the integrity of the budget.

Installing an RCD

Electrical safety standards require the installation of an RCD on large household appliances. For modern automatic washing machines, the standard for such a device is 10 mA. An RCD of 30 mA will be required for an old-generation machine or for operation in an excessively humid room to overcome the sensitivity threshold of the protection.