Most often, errors and failures of washing machines occur at the most inopportune moment. It’s just that in the middle of the program, instead of draining the water and continuing to work, the device stops and an error message appears on the screen. Errors can be different, for example, the OE error on an LG washing machine appears after the washing program has completed and the device must drain the water before rinsing or spinning. This error may indicate a serious problem with the machine or shortcomings caused by improper installation.

Most often, errors and failures of washing machines occur at the most inopportune moment. It’s just that in the middle of the program, instead of draining the water and continuing to work, the device stops and an error message appears on the screen. Errors can be different, for example, the OE error on an LG washing machine appears after the washing program has completed and the device must drain the water before rinsing or spinning. This error may indicate a serious problem with the machine or shortcomings caused by improper installation.

OE error, what does it mean?

LG washing machine shows OE error if the device fails to drain water from the tank. The error indicates that a certain number of attempts have been made to start the pump, but water still remains. There can be several reasons for this problem, among the most common:

- serious sewer blockage;

- kinked or clogged drain hose;

- the drain filter is clogged;

- the drain pump has failed;

- The water level sensor does not work;

- controller failure.

Any of the above faults may result in an error message. To quickly correct the situation, the first thing you need to do is identify the cause of its occurrence, find the faulty area.Without a doubt, this is a serious problem, but do not get upset right away, in more than half of the cases the OE error code has nothing to do with a breakdown of the machine, you just need to check and tidy up the parts of the drainage system.

Checking the sewer and drain hose

After it became clear what this error means, you need to proceed to correcting the situation. The first thing to do is to make sure that there is no large blockage in the sewer pipes. It would not be superfluous to arm yourself with a long wire, bent at the end and clean the drain to the maximum possible length.

If the machine is connected through a siphon, it must be disassembled, remove the debris accumulated during operation, rinse with running water. Often the drain of the machine is made straight, without a siphon, in this case, special attention should be paid to the connection point - this is the ideal place for a blockage to form.

Next in line should be the drain hose. Often, trying to rationally use the small area of the apartment, the machine is pushed into a corner, as a result of which it bends. A blockage forms at the bend, which the water cannot overcome. Another option is possible - the hose is too long and something heavy is installed on it, or people constantly step on it. In any of the above situations, there is only one way out - you need to change the hose.

Even if there is no visible physical damage, it would be a good idea to remove the hose and rinse it with running water. A clean drain system will reduce the load on the pump and contribute to a long service life of the machine as a whole.

Drain filter

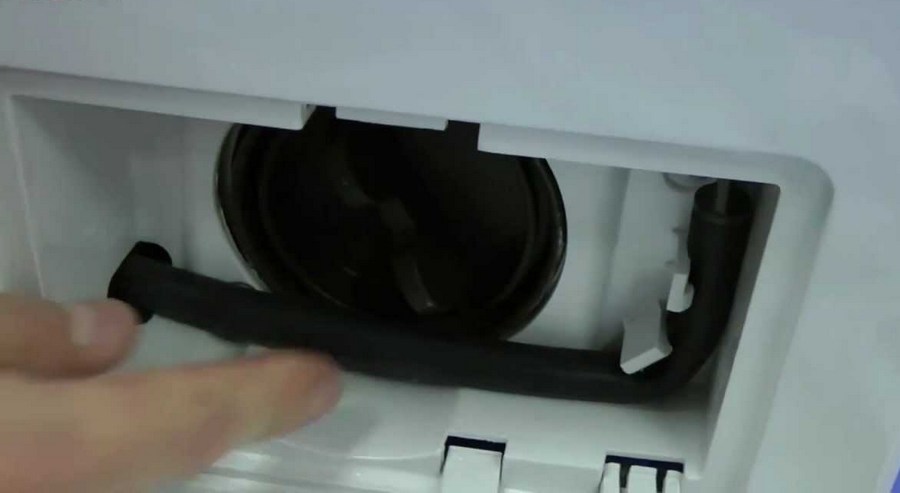

If the drain pipes are in order, there is no blockage in the sewer, and the machine still gives an OE error - you need to check the parts of the machine itself. The drain filter is the first in line.It is installed at the exit of the machine, its task is to retain small objects that could fall off during washing.

By the way, some owners of washing machines, including those manufactured by LG, do not know about this useful device, but in vain, quite often it is a dirty filter that causes a number of problems.

It’s not difficult to figure out how to fix the problem with a clogged filter; you need to remove it and clean it. Cleaning is very simple; you definitely don’t have to call a professional for this. Where exactly the filter is installed depends on the model of the washing machine, most often at the bottom of the machine, covered with a hatch or a removable panel. How to remove and clean it correctly is described in detail in the documentation for the washing machine.

Before you start cleaning the filter, you need to prepare a container for collecting water and a rag. Even if the water has been removed from the drum, it is likely that several liters will still be trapped inside.

The filter is removed, cleaned of threads, rags, buttons and other objects that are an obstacle to the free flow of water, and screwed into place. You can check if the error has gone away. If the letters OE appear on the screen again, proceed to the next step.

Drain pump

Another device whose failure can cause an error is the drain pump (pump). By the way, it is easier to determine the malfunction of this unit “by ear”. The reason for this is simple - during drainage the pump makes a loud noise. If you can’t hear its operation, or you hear crackling and other sounds unusual for the pump, it’s likely that you won’t be able to do without a replacement.

Structurally, the drain pump consists of two parts: an electric motor and an impeller. Both parts can cause the drain to not work.Troubleshooting should begin with the mechanical part. To do this, you need to remove the pump and remove it from the housing. Often the cause of impeller jamming is threads that are wound around the shaft.

The impeller and pump housing are cleaned of dirt and washed. Next we need to tackle the engine. It is easy to check the windings using a multimeter in resistance measurement mode. If the device shows an infinite value, the pump needs to be changed.

Replacing a pump is not a difficult task, but it is important to buy a quality replacement. You should not try to save money; you should only choose original spare parts. This guarantees a long service life of the machine and protects you from unplanned expenses.

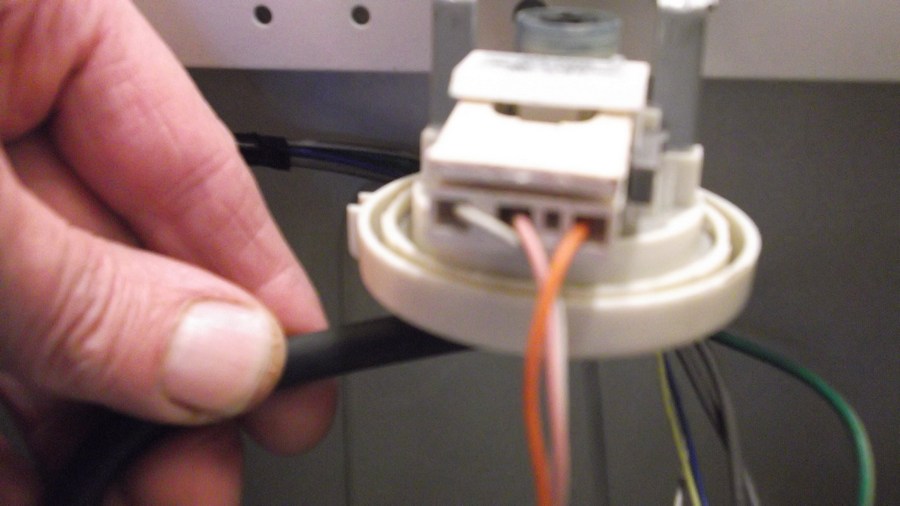

Liquid level sensor and connecting wires

A special case is that the machine drained the water normally, but does not spin, and the indicator shows an OE error message. With a high degree of probability, we can assume that in this situation the pressure switch, the water level sensor in the tank, is to blame. He stubbornly does not notice the lack of water and interferes with the implementation of the program.

Checking and replacing this sensor is also easy. It is a round part to which several wires and a tube are connected, transmitting pressure. There is no need to immediately buy a replacement; perhaps the conductors are to blame or the tightness of the tube is broken.

It would also be a good idea to ring the internal wiring of the washing mashine. The washing machine operates in conditions of high humidity, which affects the condition of the connecting chips and contact pads. If oxide is detected, it must be removed, damaged conductors and pads must be replaced.

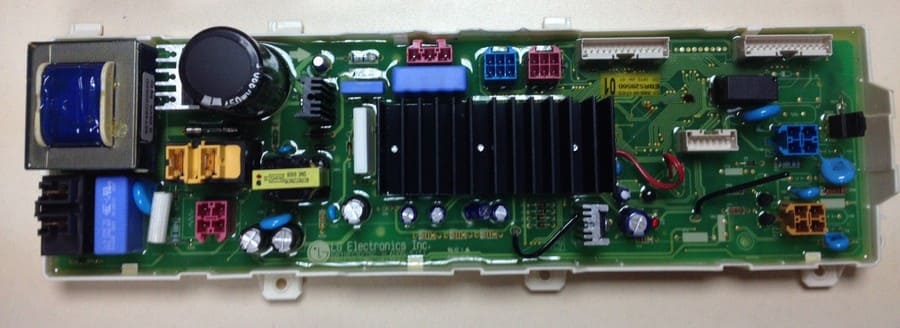

Machine control module

It is extremely rare, but it still happens that this error is caused by a malfunction in the control module or failure of electrical circuit components.What to do in this case is up to the owner to decide; it seems reasonable to take the washing mashine for repairs or call a repairman to your home. Of course, you can try to repair the device yourself, but this requires knowledge and skills of this kind of work.

If you decide to take on the matter yourself, you should start by carefully inspecting the board. Often the breakdown can be determined visually. This could be a burnt resistor or a swollen capacitor. If nothing like this is visible, everything beautiful and shiny will have no choice but to look for the module diagram and systematically check every detail.

The OE error on an LG washing machine does not always indicate a critical failure. In most cases, you can handle it on your own. This will help save time, you don’t have to wait for a technician, and, of course, money, because you only have to pay for new parts.