In the modern world, it is difficult to find a family that does not use a washing machine. Often during operation a situation arises when the washing machine does not heat the water. Most modern models have a self-diagnosis function, so they turn off in such cases, and a fault code is displayed on the display. Budget models, as a rule, do not have this opportunity. In this case, the washing process continues, which significantly prevents the timely detection of a specific malfunction.

Most often, the washing machine completely stops heating the water, which may be indicated by poorly washed clothes.You can detect and fix the problem either yourself or by contacting a specific service center for repairing washing machines.

How to determine that the washing machine has stopped heating water

The first sign is cold laundry immediately after washing, since the rinse will take place in cold water. In addition, it is worth paying attention to what program the wash is performed in. Many well-known brands of washing machines, including Indesit and Bosch, are equipped with built-in programs for silk and synthetic items that are washed in cold water. A delicate wash program may also be present.

Some washing machines from brands such as LG, Beko and a number of others have washing mode and temperature controlled by separate switches. If the specified washing parameters and the actual temperature do not match, it means that the washing machine heats the water incorrectly or does not heat it at all.

You can check the temperature compliance using the attached instructions that come with each device.

If it seems to you that the water in the drum is not heating up at all, then the check can be done without a thermometer. To do this, load the laundry into the machine and start the wash, selecting a program with a temperature of more than 60OC. When about half an hour has passed, place your hand on the hatch door and make sure it is warm. If it is cold, then the heating element of the washing machine does not heat the water.

Causes of malfunction

A washing machine is a complex mechanism that includes a huge number of elements.

If the washing machine does not heat the water, then a malfunction is possible for one of the following reasons:

- the electric water heater broke down;

- The thermostat has deteriorated;

- the electronic control unit has deteriorated;

- It is necessary to install a new water level sensor.

Partial heating occurs due to:

- incorrect connection of the washing machine to the drain system;

- The wrong washing program has been selected.

Wash temperature setting is incorrect

Before moving on to radical measures to disassemble the washing machine, it would not hurt to check the banal reason for washing in cold water. Take the instructions and study them carefully. Some modes, for example, “Delicate wash” or “Silk items”, by definition, do not use heating water.

If the specified program uses heating, check that the settings are correct. Temperature readings may simply not correspond to the program, which is why the water will remain cold. This is especially true for the newest models of washing machines, which, as a rule, are equipped with two separate program setting controls.

The heating element has failed

A water heating element fails, usually due to a voltage surge in the electrical network, a manufacturing defect, a short circuit or natural destruction of the element due to the aging of household appliances. A burnt heating element must be replaced.

Scale on the heating element

The heating element may be working properly, but heat the water to lower temperatures than set by the selected program. This happens due to hard water, which contains large amounts of calcium and magnesium salts. Salts contribute to the formation of scale on the walls of the heating element, as a result of which the heat transfer of the heating element deteriorates. In addition, the heating element begins to overheat and sooner or later will fail.

To get rid of a layer of scale, use one of the cleaning products for water heating elements. The easiest way is to take 100 grams of powdered citric acid, pour it into an empty laundry drum and turn on the wash for an hour and a half at a water temperature of 60 degrees. This time is enough to completely corrode the accumulated scale on the heating element.

Control unit failure

Sometimes the electronic control unit fails. The reason for this may be a software failure or breakdown of any electrical components.

Electrical components may fail due to short-term voltage surges. The control board may be damaged due to frequent vibration loads during the washing process. For these reasons, the normal operation of the module is disrupted, after which the signal to turn on the heating element stops.

Thermal sensor has failed

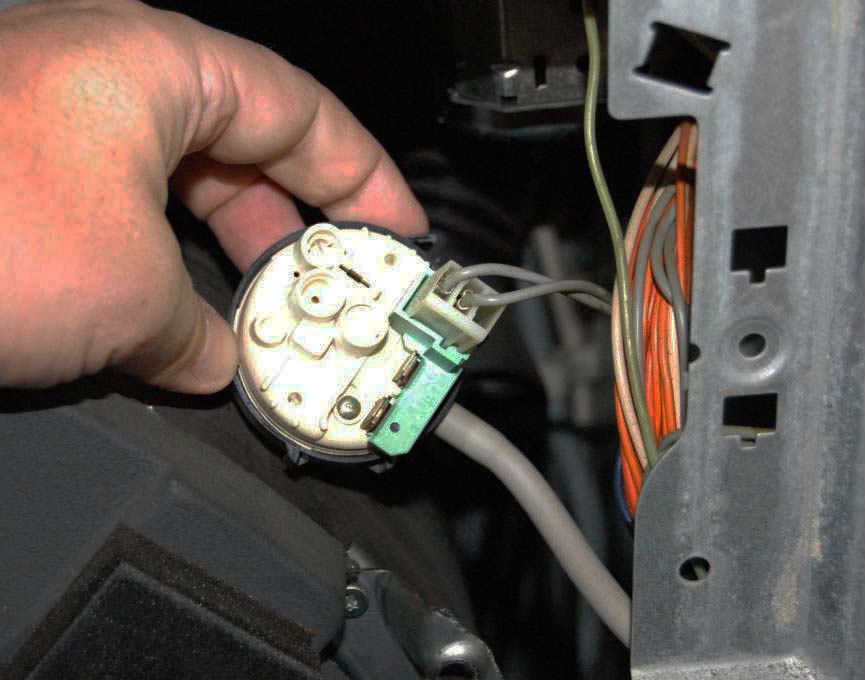

Temperature sensor location

The temperature sensor (thermostat) is designed to control the temperature inside the tank. Since any washing program has a specific temperature, the electronic control unit constantly compares the thermostat data with the programmed data from the ROM.

If the thermostat breaks down, the washing machine may either not heat the water or bring it to a boil. In the vast majority of washing machines, this sensor is located near the heating element or on the heater panel. Using a multimeter you can check whether it is working or not.

Replacing the temperature sensor with a new one occurs as follows:

- remove the rear cover of the unit;

- disconnect the connector with wires from the thermostat;

- remove the faulty sensor from the socket and install a working one in its place;

- reconnect the connector with wires.

Damage to the water level sensor

In some cases, the pressure switch becomes unusable. This device is necessary to control the water level in the tank. Using a tube connected to the sensor membrane, the pressure switch measures the pressure created by the water. Sometimes the tube becomes clogged with all sorts of small debris, animal hair, or pieces of fabric.

The owner of the device will need to clean the tube by removing the top cover. A pressure sensor will be installed on the right or left side of the housing. Simply remove the clamp and disconnect the tube for cleaning. If this does not correct the situation, then the pressure switch will need to be replaced.

The wiring to the heating element is faulty

Due to increased vibrations during spinning, sometimes a break occurs in one of the conductive circuits. The frayed wires are soldered and carefully insulated. If you have not found the location of the wiring break, you will need to contact a washing machine repair technician.

Self-draining of hot water due to improper connection of the washing machine to the sewer

If you connect the washing machine to the drain hole incorrectly, the water will flow down the drain spontaneously. It will not warm up to the required temperature due to constant draining and auto-topping.

How to identify a faulty part

During the washing process, as well as during spinning, all components of the washing machine are subject to increased vibration loads. As a result, one of the device nodes may become disconnected. To fix the problem, you will need to visually inspect all the elements and components of the washing machine and connect the fallen wire back into place.

All known models of washing machines are built on the same principle and are equipped with a heating element.They often have a tubular heating element installed, which transforms electricity into heat.

Next, we will consider ways to diagnose the most basic elements of washing machines.

Heating element diagnostics

Most often, it is the heating element that fails, which makes normal heating of the water impossible. With proper operation, the heating element can last at least 5 years. However, many people are forced to use hard water. The problem is aggravated by the use of low-quality detergents. As a result, scale appears on the heating element, its heat transfer deteriorates, and sooner or later it will definitely fail.

Electric heating elements are used in household appliances such as kettles, coffee machines, pressure cookers, boilers, and so on. There are heating elements of wet and dry types. Dry water heaters do not come into direct contact with water. However, most often manufacturers of washing machines, including Samsung, LG, Ariston and Bosch, use wet-type heating elements in their devices. The only way they differ is in shape and power consumption.

Electric water heaters with a power of about 1500-2500 W are installed in household washing machines. These indicators can always be seen on the unit body, as well as in the accompanying technical documentation. To check the functionality of the heating element, you will need a multimeter.

To get accurate results, resistance calculations should be carried out for a specific element using the formula R = U² / P, where:

- R – resistance, Ohm;

- U – mains voltage, V;

- P – water heater power consumption, W.

For example, in our case the heating element will have a power of 1500 W, then:

R = 220² / 1500 = 32.26 Ohm.

The calculated resistance for a 2000 W electric heater is 24.2 ohms.

To check the heating element we will need:

- Disconnect the wires from the heating element.

- Set the multimeter to measure resistance in the mode up to 1 kOhm.

- Place the tester probes against the contacts of the water heater.

If the heater is in working condition, the measuring device should show results close to the calculated ones. “Zero” will indicate a short circuit inside the heating element. In what case will it need to be replaced? If the tester shows a “one” or an infinity symbol, then a break has occurred in the water heating element, and it will also need to be replaced.

To find out whether the water heater has penetrated the housing, you will need to switch the multimeter to the “buzzer” dialing mode, and touch the housing of the heating element with one of the probes of the device. If a breakdown appears on the tester display, numbers will appear or a sound signal will sound.

Control module diagnostics

It will be almost impossible to detect and eliminate this defect yourself, so it is best to entrust this work to an experienced technician.

But if you still decide to fix the problem on your own, then remember that all work on troubleshooting and repairing the internal components of the washing machine must be carried out with the obligatory disconnection of the device from the electrical network.

Checking the water level sensor

If the heating element is not damaged, you can then check the pressure switch. If it is clogged, the control unit does not receive a signal from the tank about filling with water. Because of this, the command to turn on the water heater and close the inlet valve is not sent.

To check and correct possible problems with the water level sensor, you will need to do the following:

- disconnect the washing machine from the power supply;

- Based on the device model, remove the back or front panel;

- disconnect the power wires and the electric heater;

- visually inspect the pressure switch;

- remove and clean the water sensor tube, check for leaks.

Checking the temperature sensor

If everything is in order with the heating element and pressure switch, you need to check the temperature sensor. Quite often, the water in the washing tank does not heat up precisely because of it.

Most often it is installed on the body of the water heater. It is made in the form of a small metal cylinder, to which power wires fit. Although in some washing machines it may have a different appearance.

To check the temperature sensor you will need to perform the following steps:

- remove the sensor from the tank, having first disconnected the wires from it;

- use a tester to check its resistance;

- lower the temperature sensor into hot water and measure the resistance again;

- compare the results - if they are almost the same, then the sensor must be replaced.

Debugg

A number of problems with the washing machine can be resolved on your own without involving a technician from the service center. To determine the cause of the failure, you will need to conduct diagnostics.

Self-diagnosis can be carried out for the following elements of the unit:

- Water level sensor (cleaning of small debris).

- Water heater (removal of scale and rust).

- Wiring.

Some components of the washing machine can be checked using a multimeter, if necessary, replacing failed elements with new ones. An exception may be a programmer or control unit, the repair of which will need to be entrusted to a specialist.

If you do not find any faults with the above components of the washing machine, check that the device is connected to the drain correctly.

For this:

- Unplug the washing machine.

- Check all hoses.

- Clean the filters.

- Install the ball valve.

- The drain hose should be located at a height of 50-100 cm from the floor.

It is best to drain through a sink or bathtub siphon.

In what case is it better to contact a specialist?

If you are unable to diagnose the reason why your washing machine is not heating the water, seek professional help.

Preference can be given to a service center master because:

- Professional repair services will be provided at a time that is convenient for you.

- There is no need to transport large household appliances to the workshop. The master will be able to carry out all the repair work at your home, taking with him all the necessary high-quality tools.

- The technician deals with faults in washing machines every day, so he will complete all the work as quickly and efficiently as possible.

- The correct electronic modules for your specific washing machine model will be installed.

- The cost of repairing such equipment is affordable to almost everyone. It is possible to save money by using inexpensive, proven analogue spare parts. At the same time, almost one hundred percent quality of the finished device will be preserved, in comparison with the use of original components.

Conclusion

To ensure that your washing machine serves you well for many years, take the following preventive actions:

- Before starting the unit for the first time, carefully read the instructions;

- If you use the washing machine with hard water, add softening agents during washing;

- From time to time, carry out the washing process idle, adding citric acid powder or vinegar to the drum;

- Sometimes check the pressure switch tube and clean it.

If you follow these simple rules, the chance of your water heater failing is almost zero.

It is worth noting that it is highly not recommended to operate a washing machine with a broken heating element, since low water temperature impairs the dissolution of the powder, which leads to stains on clothes.

In addition to the banal deterioration in the quality of washing, a breakdown of the water heater may indicate the occurrence of more serious problems with the washing machine. If the control module or equipment control detector is damaged, the washing process itself may become unsafe.

That is why timely diagnosis and minor repairs are so necessary. It is better to incur minor financial costs now than to purchase a new device at the most inopportune moment in the future.