After a certain period of operation, washing machines lose their ability to operate normally and are replaced by more modern models. The basis of each such washing machine is an electric motor, which, after disassembling the device, can be used. The power rating of the dismantled motor is at least 220 V, the rotation speed reaches 11,000 rpm, which is very suitable for using such motors on the farm. Today we’ll try to figure out how to connect a motor from an old washing machine in order to be able to use its potential.

After a certain period of operation, washing machines lose their ability to operate normally and are replaced by more modern models. The basis of each such washing machine is an electric motor, which, after disassembling the device, can be used. The power rating of the dismantled motor is at least 220 V, the rotation speed reaches 11,000 rpm, which is very suitable for using such motors on the farm. Today we’ll try to figure out how to connect a motor from an old washing machine in order to be able to use its potential.

Connecting a motor with a starting winding

First, using a tester, we find the corresponding output pairs. By ringing the wires, we identify the pairs, after which we find out which of them is the starting one and which is the working one. A higher resistance value corresponds to the starting pair creating the initial torque.

On some washing machine engines, contactors can be replaced with small capacitors, which is very convenient for operating washing machines. And when the motor is started without load, this type of motor is able to start working on its own, without a capacitor and initial power supply from the start winding.

When the engine heats up, the reasons are as follows:

- bearings are worn out;

- the gap decreased, and the rotor and stator began to come into contact;

- high capacitor capacity.

To make sure the engine is working properly, you need to let it run for one minute and check the heating. In such a short time, the heat will not have time to disperse through the parts, and it is possible to accurately track the point of strong heating - a bearing, stator or something else. This is then checked three times after five minutes of operation.

Brushed motors

These are motors that do not have a starting winding. They can operate on both direct and alternating current and do not need to be connected via a capacitor. Motors of this type have from five to eight terminals, but such a number will not be needed for further operation of the unit. Therefore, you will have to identify and disconnect the contacts going to the tachometer, thermal protection, etc.

Expert advice

When deciding to connect a motor from an old washing machine to use it for new purposes, you need to know two important conditions:

- a capacitor is not used when connecting;

- there is no need for a start winding.

To make it more convenient to understand the transfer case wiring, you need to know its color codes:

- a pair of white wires comes from the tachogenerator and will be used in the future;

- wiring in red and brown shades leads to the rotor and stator winding;

- graphite brushes are connected with gray and green wires.

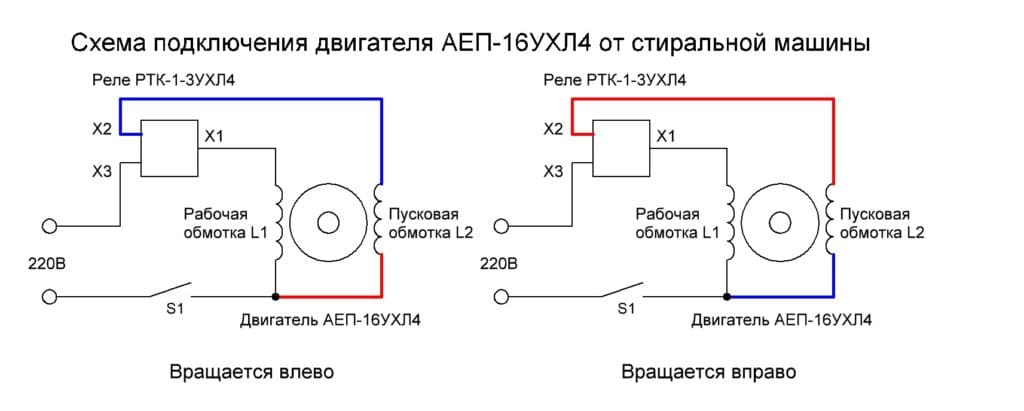

Connection diagram

To proceed further, you should study the electrical connection diagram, which does not cause any particular difficulties in operation even for an ordinary user.

To begin with, take the wires that supply the stator and rotor of the washing machine. The stator winding is connected to the rotor brush. For this purpose, an insulated jumper is installed. The remaining two wires are connected to a 220 V home network.

To change the direction of rotation, you just need to move the jumper to other terminals. To make it convenient to start and stop the motor, the necessary buttons are added to the circuit.

Speed regulator

The motor from the old machine for washing clothes differs in a higher number of revolutions per minute, for this reason you will have to connect a regulator that ensures operation at different speed modes and protects the motor from overheating. For these purposes, a simple light intensity relay is used, but it will have to be slightly modified:

- The triac complete with radiator is removed from the washing machine. This semiconductor in the electronic control circuit is designed to turn off the unit;

- the element is soldered into a relay microcircuit instead of a low-power part. It is better to entrust such work to a master.

Motor application options

After disassembling the old washing machine, the electric motor can be installed on one of the devices.

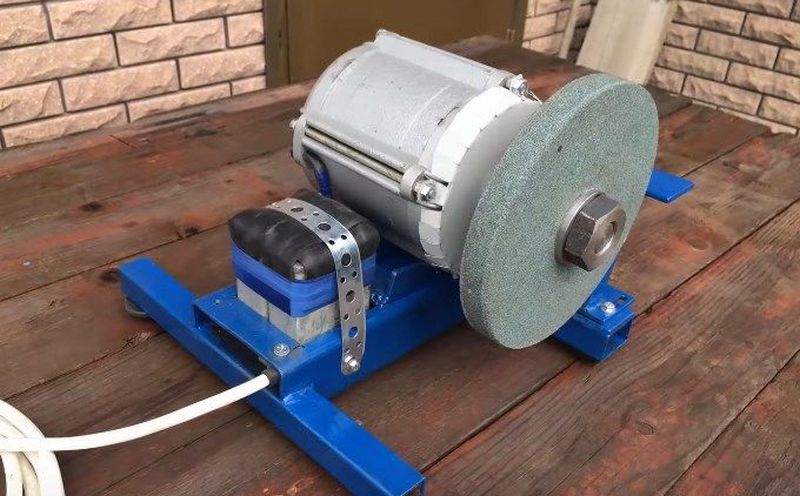

Grinder

Sometimes a difficulty arises here - the hole in the stone differs from the size of the shaft of the electric motor.You will have to machine an additional part that will act as a transition element. For fixation, a nut with a thread direction that takes into account the direction of rotation of the motor is used. Otherwise, the direction of the torque is changed by switching the wiring to opposite contacts.

Having connected the winding to the mains, the starting pair is connected to the coil. The second end of the wiring is briefly applied to the winding terminal to check the direction of movement of the motor.

To design sharpening machine, It is best to use a motor that can withstand voltage in the range of 150 - 200 V. In this case, a rotation speed of the stone of 1,000 revolutions is enough to prevent it from breaking.

Vibrating table

An excellent use for a motor from an old machine if you are making paving slabs.

Structurally, such a table does not cause any difficulties. To make it, a flat surface in the form of a plate, fastened to the base with movable elements, is sufficient. The commutator motor will provide the necessary vibration.

Concrete mixer

The motor can be used in this way as well. Such a unit will not provide industrial volumes, but it will significantly facilitate household work.

It is noteworthy that along with the motor you will have to use the washing machine tank. It is best if the container is of the activator type - instead of the standard element, a pair of steel blades is installed, externally resembling the letter “P”. They are positioned in such a way as to create a right angle. The tank drain hole is securely closed.

The power of the motor of the old washing mashine selected for connection is determined by the volume of work to be done. To prepare concrete in small quantities, it is enough to use a single-phase motor.

We will also have to resolve the issue with the belt drive installed in the washing mashine. It is best to replace it with a gearbox that can reduce engine speed.

Hand mixer

Using this device, you can mix mortar for plastering and adhesive for laying tiles.

Lawnmower

The engine from a washing machine is an excellent solution in terms of power and size to make a wheeled lawn mower. You will need a wheeled platform in the center of which the engine is installed. From it a direct connection is made to the knives located below. The cutting height is adjusted by the fit of the wheels in relation to the base of the mower.

In addition, from a used washing machine you can also construct:

- and much more.