Very often, during operation of a washing machine, its motor fails. Knowing how to check the engine of a washing machine, you can try to restore it or, if repair is impossible, decide to replace it. This article will help you figure it out.

Very often, during operation of a washing machine, its motor fails. Knowing how to check the engine of a washing machine, you can try to restore it or, if repair is impossible, decide to replace it. This article will help you figure it out.

Engine types

The following types of motors are most often used in washing machines:

- asynchronous;

- collector;

- engines having direct drive.

Let's take a closer look at each type of engine and how to check its serviceability.

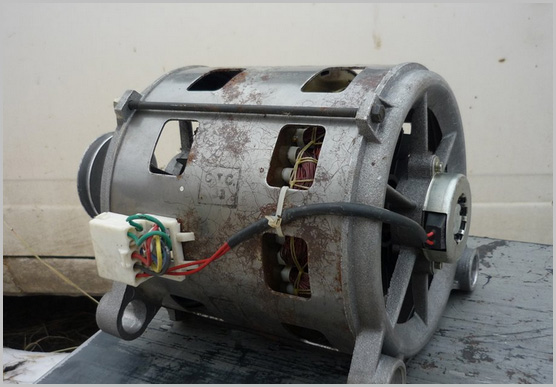

Asynchronous motor

This motor has been used in washing machines before. It does not have high efficiency and therefore is almost never used in modern machines. Compared to modern electric motors, it is the simplest and most reliable, and therefore breaks down much less frequently than other types of motors.

It is quite difficult to check the serviceability of this type of engine at home. It is directly connected to the drum. But if you still manage to get close to it, then you need to know that most often the engine breaks down due to wear of the bearings. There are two of them in the electric motor.

With their help, the rotor shaft rotates. Also common, but less common, is winding breakage.If the washing machine is stored and operated incorrectly, you may encounter a motor defect such as a violation of the insulation of its windings.

The first thing to do is make a visual inspection. This applies to all types of engines. It is necessary to pay attention to the integrity of the paint on the engine body. Its absence in some places may indicate excessive heating of the motor. A visual inspection of the engine is best done by disassembling it.

The procedure for disassembling an asynchronous motor:

- unscrew the screws;

- make marks with marks, the location of the covers relative to the body;

- remove the fan by unscrewing two bolts;

- Remove the front and rear engine covers by first unscrewing the screws.

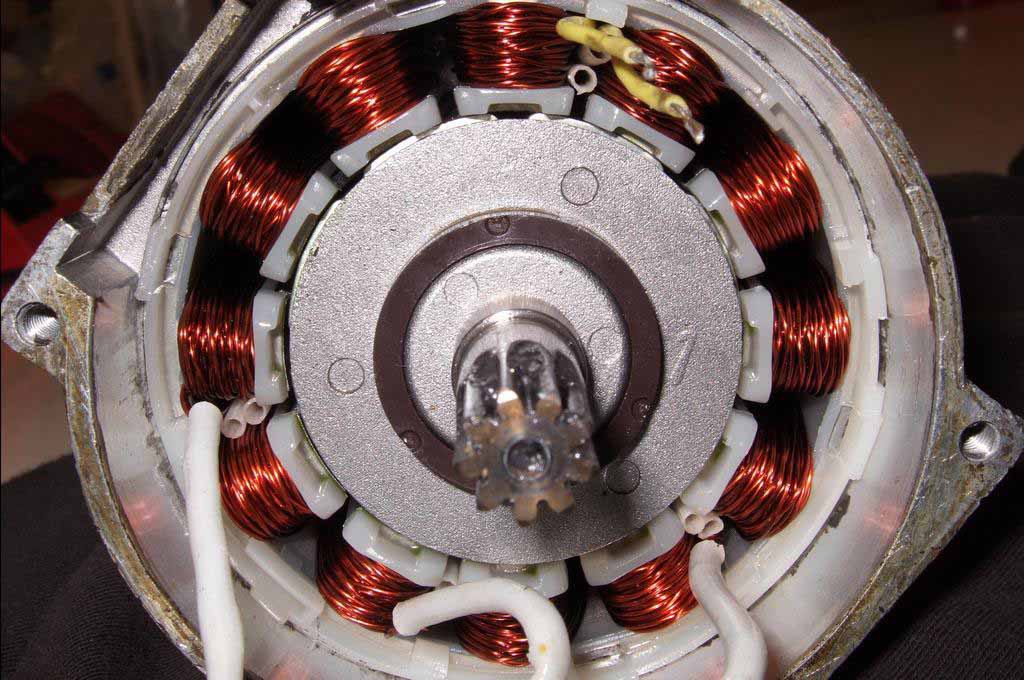

The rotor needs to be inspected. Upon inspection, you can identify damage associated with melting or blackening. In this case, the rotor must be replaced. Next, the stator is inspected. Upon inspection, you may find faded insulating varnish. This may indicate an interturn short circuit. The winding in this case requires rewinding. But it is better to replace the entire part.

If a visual inspection does not bring any results, you need to use a multimeter to verify the integrity of the windings. The starting and operating windings must be checked. An asynchronous motor from an old washing machine has three outputs. All windings are checked among themselves, as well as with the housing. If the device shows at least some resistance, it means there is a breakdown of the windings. In this case, the engine is submitted for stationary repair to rewind the windings.These are the main methods for checking an asynchronous motor at home.

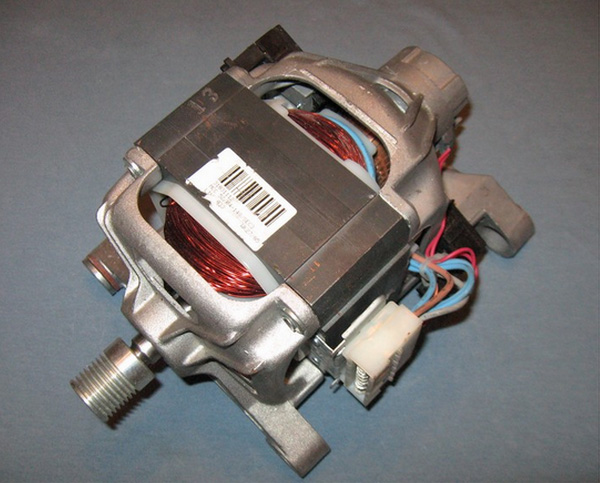

Brushed motor

The electric motor is often used in modern washing machines. It has a belt drive with a drum and is easily removed from the unit, so checking the serviceability of the engine is not difficult.

The motor should be removed from the washing machine body, having previously unscrewed the housing wall. It is usually located under the tank. After removing the motor, the rotor and stator are connected in series.

A voltage of 220 Volts is supplied to the ends of this electrical circuit. For safety, a load element greater than 500 Watts should be connected in series to the circuit. To do this, a heating element or some powerful heating element is connected in series to the circuit. This inclusion will prevent the motor from complete failure in the event of a short circuit in the windings.

Causes of washing machine motor malfunctions.

Most often, an electric motor can have the following causes of malfunctions:

- Failure of electric motor brushes;

- Failure of lamellas;

- Broken rotor or stator.

Motor brush faults

First of all, you need to inspect the motor brushes. They are made of graphite and are constantly subjected to friction against the collector. Therefore they fail very often. If the machine has been working for several years, they definitely need to be checked.

They can also fail if the washing machine is used in violation of the operating instructions. For example, if the machine's drum is constantly overloaded with laundry. The brushes should be carefully inspected. They should not be very short compared to new graphite brushes. They may have cracks and chips.

If there is strong sparking during engine operation, the brushes should be replaced . It should also be remembered that new brushes can spark for some time. This happens because they have not yet been adjusted to the engine parts. You can replace the brushes with new ones as a preventive measure, and not wait until they are completely worn out.

Peeling or breakage of lamellas

The lamellas are small plates and serve to transmit current from the rotor winding to the engine. They can peel off due to severe overheating, in case of improper operation of the washing machine. Since they are glued to the rotor, in this case they can simply come off. If you hear a crackling sound when slowly rotating the rotor by hand, then in all likelihood there is a problem with the lamellas.

In this case, the engine may jam. Minor peeling of the lamellas can be eliminated at home using fine sandpaper. In the workshop, such a defect is eliminated using a special machine.

After processing, the space between the lamellas must be thoroughly cleaned of shavings and dust.

The lamellas may have another breakdown, this is a break in the wire going from the lamella to the rotor windings. Usually this happens at the place of its attachment. In this case, you can fix the malfunction using a soldering iron. You can detect such a defect if you lightly tug each wire with tweezers.

Rotor or stator malfunctionsThey can also fail if the washing machine is used in violation of the instructions for use. For example, if you constantly overload the machine tank with laundry. The brushes should be carefully inspected. They should not be very short compared to new graphite brushes. They may have cracks and chips.

If there is strong sparking when the engine is running,

brushes need to be replaced

. We must also remember that new brushes can spark for some time. This is due to the fact that they have not yet gotten used to the engine parts. You can replace the brushes with new ones for preventive purposes, and do not wait until they are completely worn out.

The lamellas are small plates and serve to transmit current from the rotor winding to the motor. They can peel off due to severe overheating if the washing unit is not used correctly. Since they are glued to the rotor, in this case they can simply come off. If you hear a cracking sound when you slowly rotate the rotor by hand, then in all likelihood there is a problem with the lamellas.

In this case, the engine may jam. Minor peeling of the lamellas can be repaired at home using fine sandpaper. In the workshop, such a defect is eliminated using a special machine. After processing, the space between the lamellas must be thoroughly cleaned of chips and dust.

The lamellas can have another breakdown, this is a break in the wire running from the lamella to the rotor windings. This usually happens at the place where it is attached. In this case, you can fix the problem using a soldering iron. You can detect such a defect if you lightly tug each wire with tweezers.