The main link of any modern washing machine is the engine. If this unit breaks, the equipment will stop working. Replacing a motor by professional specialists is very expensive, so users are often interested in how to remove a washing machine motor on their own at home. This process is simple if you know the correct procedure.

The main link of any modern washing machine is the engine. If this unit breaks, the equipment will stop working. Replacing a motor by professional specialists is very expensive, so users are often interested in how to remove a washing machine motor on their own at home. This process is simple if you know the correct procedure.

Types of engines

When disassembling and repairing a washing machine motor, you need to take into account its type and relevant design features. There are three known types:

- Collector.

- Asynchronous.

- Inverter.

The first type is the simplest; it is a metal case containing a stator, rotor and tachometer. To establish contact between the motor and the rotor, the design also includes two brushes; they supply current to the armature, a magnetic field is created and rotation begins. The speed of the latter directly depends on the network voltage. This motor is installed at the bottom of the washing machine and is connected by a belt to a pulley. The disadvantages of a commutator motor include brushes that wear out over time and a belt that breaks or stretches.

The asynchronous type is practically not found today.It can be two-phase or three-phase, consisting of a stationary stator and a rotor that rotates the drum using a belt. It is simply designed, unpretentious, low cost, and easy to repair. The disadvantages include low power, due to which the drum at any moment can begin to rotate much weaker and make incomplete revolutions. This seriously affects the quality of the wash. That is why the asynchronous motor is practically forgotten today and is not used.

How to remove and replace the motor of an automatic washing machine

How to remove a brushed motor

Thus, commutator-type engines usually have to be repaired. The process of disassembling an automatic washing machine, then removing the motor, repairing it or replacing it with a new one is very similar to equipment from various manufacturers, but there are also differences. It looks like this:

- Disconnect the device from the network and wait a few minutes until the equipment is completely de-energized.

- First, the device owner needs disassemble the washing machine. To do this, you will need to remove the back cover (Ariston, Zanussi, Electrolux) or the front panel (Bosch, Samsung, LG), depending on the manufacturer. In the first case, you will need to unscrew several screws; in the second, you will need to remove the top cover and control panel.

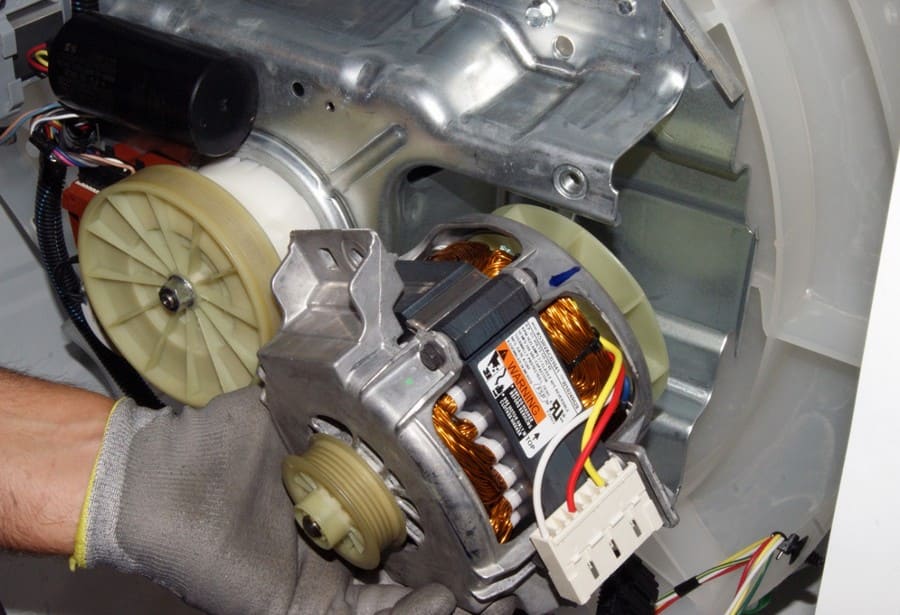

- The commutator motor is most often located at the bottom of the washing machine, under the tank. First of all, you need to remove the belt and disconnect the ground wire and power.

- Typically the motor is installed on four seats. It is firmly screwed to two of them. It is necessary to unscrew the fasteners; for this, a 13 key is used, but other options are possible, depending on the brand of the washing machine.

- Very often the engine gets stuck in the seats, so you need to pry it out with a screwdriver.

- Once you feel that the motor is moving, you need to pull it towards you and remove it.

To install a new engine, perform these steps in reverse order. In order not to mix up the wiring, it is necessary to photograph it before disconnecting or making notes.

How to remove an inverter motor

The inverter motor installed on the washing machine is not intended for repair at home, but if the user nevertheless decides to remove it himself, he will have to perform the following steps:

- Unplug the washing machine.

- Unscrew the mounting bolts and remove the back cover or front panel.

- Take a photo or mark the wiring, then disconnect it after unscrewing the retaining screws.

- Remove the bolt holding the rotor. During the process, to avoid rotation, you should hold the rotor with your hand.

- Remove the rotor assembly, then the stator.

- Disconnect all wire connectors.

How to remove and replace the motor on an activator-type washing machine

In activator-type devices (Malyutka washing machine, some compact top-loading washing machines), an activator is located on the motor shaft to create water movement.

To remove the engine in such devices, you need:

- Remove the plug from the housing behind which the motor is hidden.

- Align the hole in the impeller and the notch in the rotor by manually turning the activator.

- Use a screwdriver to lock the rotor by inserting it into the hole.

- Disconnect and remove the activator (if the washing machine was manufactured before 1985, turn the part clockwise, otherwise counterclockwise).

- Pull out the drive mechanism, then remove the motor.

Trouble-shooting

To identify the malfunction, you need to start the engine. To do this, you need to make a series connection of the stator and rotor windings, and then supply alternating current with a power of 220 Volts through the free connectors. The motor will begin to rotate.

If the washing machine is many years old, the brushes will be almost worn out, and strong sparking will be noticeable when the motor is running. The whole brushes are long and have no external defects. Otherwise it is necessary Remove the brushes from the motor and replace. New parts should be purchased only original ones, this will significantly increase the life of the washing machine.

Strong noises, heating of the motor, and insufficient operating power indicate a faulty winding. To verify this, you need to take a multimeter, select the ohmmeter mode and measure the resistance on adjacent lamellas. The difference should be no more than 0.5 Ohm. Otherwise, the user will see a short circuit between the turns. In the same way, you need to check the operation of the stator. Next, you need to diagnose the short circuit of the windings to the stator or rotor housing.

To make sure that the lamellas are worn, you need to remove the rotor from the motor and inspect the collector. A malfunction will be indicated by peeling of the lamellas, the appearance of burrs, or a break in the supply contact. All this leads to sparking of the brushes. Usually the lamellas overheat and peel off if the rotor becomes jammed or an inter-turn short circuit occurs.

Another popular washing mashine malfunction is a broken or slipped belt. In cases where this problem occurs frequently, this may indicate a faulty pulley. It will need to be replaced. You need to disassemble the washing machine, remove the belt, unscrew the fasteners, remove the pulley from the engine and replace it with a new one.

Bottom line

Today at washing machines Two types of motors are installed - inverter and commutator. The first type rarely breaks down and is very difficult to repair at home, so you should contact a service center. If the commutator motor breaks down, the cause may be worn out brushes, damage to the winding or lamellas. You can perform diagnostics yourself; to do this, you need to remove the engine and inspect it. Usually the fault is caused by brushes, which can be replaced on your own.