The drum is the central part of every laundry washing machine. The process will not start if it rotates poorly or remains completely motionless. In such situations, you should correctly determine the cause of the malfunction and try to eliminate it on your own. This way you will save money and restore functionality to the washing machine. You should know that the reasons why the washing machine drum does not spin well can be different, and there are different methods for solving them.

The drum is the central part of every laundry washing machine. The process will not start if it rotates poorly or remains completely motionless. In such situations, you should correctly determine the cause of the malfunction and try to eliminate it on your own. This way you will save money and restore functionality to the washing machine. You should know that the reasons why the washing machine drum does not spin well can be different, and there are different methods for solving them.

Why does the drum rotate poorly?

In such a situation, you should definitely be concerned about the reasons for the breakdown. Based on this, the most suitable methods of repair work will be assigned. Often problems with element rotation include the following:

- Overload. Many modern washing machines that have special sensors do not start the process if there are too many items in the drum. When you suspect that you have overloaded the machine, it is recommended to cancel the program and take out a couple of things. This measure will allow the machine to continue operating as usual.

- Worn drive belt. In such a situation, rotation of the drum will only be possible by hand; the electric motor will not do this. However, the belt might not wear out, but simply fly off from the landing site.

- Electric motor brushes are worn out.In washing machines with commutator electric motors, this place is the most vulnerable. If the required motor maintenance has been performed over the entire period of operation, then there is a possibility that the brushes will have to be replaced. As a rule, after such a procedure, the machine is fully able to work.

- The electronic programmer has failed. The most complex breakdown, because the work of reflashing or replacing the modular unit will require certain financial expenses.

- The electric motor is malfunctioning. When the drum rotates unevenly or does not rotate at all, the problem may lie in the electric motor. It probably broke, or a short circuit occurred - more likely problems in this situation. The repair is complex; it is recommended to hire an experienced specialist.

We figure out the problem ourselves

Primary diagnosis of breakdowns will be within the capabilities of any user. To do this, you must follow certain procedures:

- check the maximum weight of the laundry in the operating instructions;

- check that the door is not locked. As a rule, the drum stops spinning if the water drain filter is clogged;

- We try to turn the drum with our hands. If everything is normal, and a problem is observed during the automatic washing process, you should look for the cause in the wires, tachogenerator device, control module;

- It is imperative to inspect the cavity between the machine tank and the drum for the presence of foreign objects. If everything is normal, the heating element may have failed. The drum may also stop rotating due to a non-working heating element, thereby completely blocking the washing process;

- inspect the drive belt.It should be corrected or completely replaced with a new analogue;

- The machine is disassembled and inspected to see if there are any problems with the bearings. It is quite possible that they also need to be replaced.

We carry out repairs

Let's consider how to act in a given situation:

- A foreign object has entered. Such situations arise quite often when we forget to check our pockets before washing. All small items in most cases remain in the drum itself or the sealing element surrounding the loading door. Sometimes, during washing, such items fall into the gaps created by the drum and tank of the machine and get stuck there, becoming an obstacle to normal rotation. This suspicion is verified quite simply. First we try to rotate the drum manually. If it stands still, it means it is fixed by some thing or foreign object. To find out their location in relation to the tank, you should slowly rotate the drum with your hands, shining a flashlight into the space. To gain access, you will have to remove the heating element and pull out the foreign object through the resulting niche. Magnets or wire hooks can be a good help for this type of work. The problem is, if something is stuck in the top or side, you will have to disassemble the tank. This is not the best solution, because then you will have to seal the seams with sealant or cold welding.

- Bearing failure. You cannot turn the drum with your hands, or do it with great difficulty, hearing creaking and grinding noises? Most likely, the problem is hidden in the seals and bearings. The first element is represented by special sealing seals that protect the bearings from moisture.Gradually, its integrity deteriorates, the liquid begins to wash away the lubricant on the bearings, causing corrosion. The breakdown is eliminated by completely replacing the failed elements. The work is complex, it is recommended to invite a specialist. By the way, the process is expensive. For example, on Samsung machines, its cost is such that it is better to purchase a new washing machine.

- The filter is clogged. At such moments, the machine stops in emergency mode, stopping the process and blocking the door. You can clean the filter yourself. The operating instructions describe the procedure in detail. Most often it is located at the bottom. Carefully unscrew the lid, clean the element and drain the remaining water in the machine. Before performing such work, it is recommended to place a sufficient number of rags under the washing machine to absorb any water spilled on the floor.

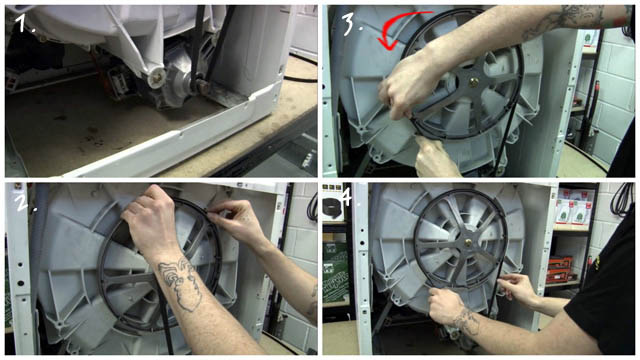

- The drive belt has fallen off. It is stretched from the drum to the motor, and from long work it stretches, stopping normal torsion. With the unit switched off, you can perform a check - spin the drum. If the movement is free and there is no noise from the electric motor, then it is the belt that is damaged. It often falls off due to uneven loading or overloading of machines, dries out, loses elasticity, and becomes brittle. To check its condition, you can remove one of the side panels of the washer. A belt that has fallen off is installed using the principle of a bicycle chain. If necessary, a new analogue is purchased. The belt is pulled with such force that when you touch it, it should make a ringing sound.

- Motor failure. In older models, the capacitor most often fails - a cylinder installed next to the motor.If it fails, the engine is unable to turn on, and the drum, naturally, also does not rotate. In such a situation, it is necessary to replace the capacitor. A common occurrence is brush wear. Over time, they become short and no longer reach the engine manifold, without transmitting the rotational process to it. The problem is solved by replacing the brushes and first cleaning the commutator from dirt. The motor is dismantled. To do this, remove the back panel and turn the washer on its side. The mounting screws are unscrewed and the terminals with wires are disconnected. After installing the brushes, rotate the motor pulley. If it works without noise, then the job has been done correctly.

- Problem with wires. It is possible that there is no voltage in the wiring. This may happen due to a failure of the control module or a malfunction of the wires powering the electric motor. Each element will have to be checked with a tester, isolated or completely changed.

- Uncontrolled opening of the drum doors occurs. This is typical for models with vertical loading of laundry. The doors swing open even during the washing process, although the design of the elements completely eliminates this possibility. The worst thing is that the tank is destroyed or the drum becomes deformed. Intervention by an experienced specialist is required.

- Failure of the module responsible for control. It is responsible for the performance of each individual washing machine unit. Incorrect operation may cause the drum to stop. You will have to replace the element or try to repair it. This will require knowledge and special skills, otherwise independent actions can only aggravate the problem.

Useful tips from experts

When using a washing machine, it is recommended to follow some important requirements to protect the drum and other components from possible damage:

- always empty pockets when sending items to the wash;

- load the maximum permitted weight, in case of overload - stop the program to lighten the drum;

- do not try to forcibly turn the drum for a long time if it has stopped working. This is allowed only to check the causes of the breakdown;

- be careful with scale removal products. It is recommended to purchase them only in specialized stores, use in accordance with the instructions;

- when replacing elements that have lost their functionality, purchase only branded analogs that match your marking. Counterfeit parts will not be able to work for a long time and will cause more malfunctions.

By following these simple rules, you can extend the service life of your washing machine.

Conclusion

Remember that only the functionality of the drum will determine how well the laundry is washed. When it rotates poorly, it is necessary to urgently search for the malfunction, determine the probable causes and organize the elimination of the problem. In conventional units, things are washed in perforated drum elements. They are equipped with special ribs to enhance the mixing process. When spinning, the contents of the drum are pressed against the walls, and under the influence of centrifugal force, they rise to the top. The lifting of things continues until the friction force becomes lower than the moment created by the weight of the laundry. Then the things rush down into the water with washing powder, and rise again.When using a washing machine, it is recommended to follow some important requirements in order to protect the drum and other components from possible damage:

Always empty your pockets when putting things in the wash;

Repair

Repair Vestel washing machine - malfunctions and do-it-yourself repair

Vestel washing machine - malfunctions and do-it-yourself repair