Indesit technology is particularly popular today, due to its efficiency and affordability. However, sometimes it breaks. Malfunctions can be divided into two groups: serious and non-serious. If in the first case the help of a specialist is required, in the second situation you can do it on your own.

It remains only to consider what exactly is serious and not so important. Failures that require outside intervention include problems with the pump, bearing, heating element, belt, shock absorbers, electric motor brushes and drum.

Minor failures include failure of the device to turn on, lack of water filling or continuous filling, presence of extraneous sound, excessive foam formation.As well as the lack of operation of the drain system, increased vibration volume, and blinking indicators of additional options. How to repair an Indesit washing machine will be discussed in this article.

Features of Indesit washing machines

The model range of washing machines of this brand can include full-size and compact devices. The units are produced with front and vertical loading. The products include a screen that can have any size, depending on the model. It allows you to monitor the washing process and choose the best options. Sometimes it is missing; in such situations, indicator lights directly above the buttons are used instead.

Over time, even the most reliable pieces of equipment can fail. Repairing them sometimes costs a lot of money, so some owners of automatic machines strive to repair them themselves. And this is not prohibited, especially if the faults are classified as “non-serious”. However, unfortunately, most problems are solved exclusively at the service center.

Troubleshooting methods

There are several options for determining whether a device is faulty. It’s worth noting right away that some series of units provide a test mode, based on which it will not be difficult to determine the type of failure. Such devices are equipped with a display that shows the main errors. If there is no screen, when difficulties arise, a certain button lights up, most often it is even a combination of LEDs.

Simple reasons why Indesit washing equipment does not work

There are several simple and obvious reasons why Indesit equipment refuses to work. Each of them deserves special attention and requires detailed consideration.

Heating element malfunction

This problem is indicated by error code F07, which is displayed on the display. This malfunction can also be determined based on external characteristics. In the case of washing at high temperatures, there is no heating of the hatch window, and the quality becomes significantly worse. If the heating element is broken, even an ignorant person can fix it. But only on condition that he follows a certain algorithm of actions:

- unscrewing the bolts using a screwdriver in the rear wall area and removing it from the body part;

- search for a heating element in the lower part of the tank of a device equipped with two contacts, as well as a grounding bolt, which is located in the middle;

- measuring the voltage level using a multimeter: if it is equal to the zero mark, the problem is in this part;

- unscrewing the fasteners in the middle, removing the seal and removing the element from the socket.

You can understand the fact that the malfunctions relate specifically to the heating element based on its appearance. If a large layer of scale is found on the part, the heating element must definitely be replaced. Installation occurs in the reverse order of dismantling.

Electric motor failure

In most washing machines produced under the Indesit brand, the motor works more than perfectly, but, as with any other equipment, breakdowns occur. The cause of failure of the “heart of the SMA” may be due to natural wear and tear or significant stress.The order that must be followed to disassemble the unit and find out the cause is as follows:

- removing external panels from the unit, traditionally we are talking about the top and rear elements;

- disconnecting the wires that supply power to the motor;

- removing the belt from the pulley;

- unscrewing the fasteners and removing the motor.

After completing the diagnostic procedure, the owner of the device makes the final decision, which may involve repairing or replacing the motor. Most often they choose the latter option due to the difficulty of rebuilding the engine.

Replacing motor brushes

Practice shows that brush wear occurs when equipment is used for a long time. This type of failure can be determined by seeing sparks from the engine or the size of the elements, since they become smaller during the process of abrasion. A good part does not contain cracks or chips. A break can be observed in the stator or rotor area. In this case, it is worth replacing the spare part completely. To do this, you need to remove the old part and install a new element in its place, following a certain sequence of actions.

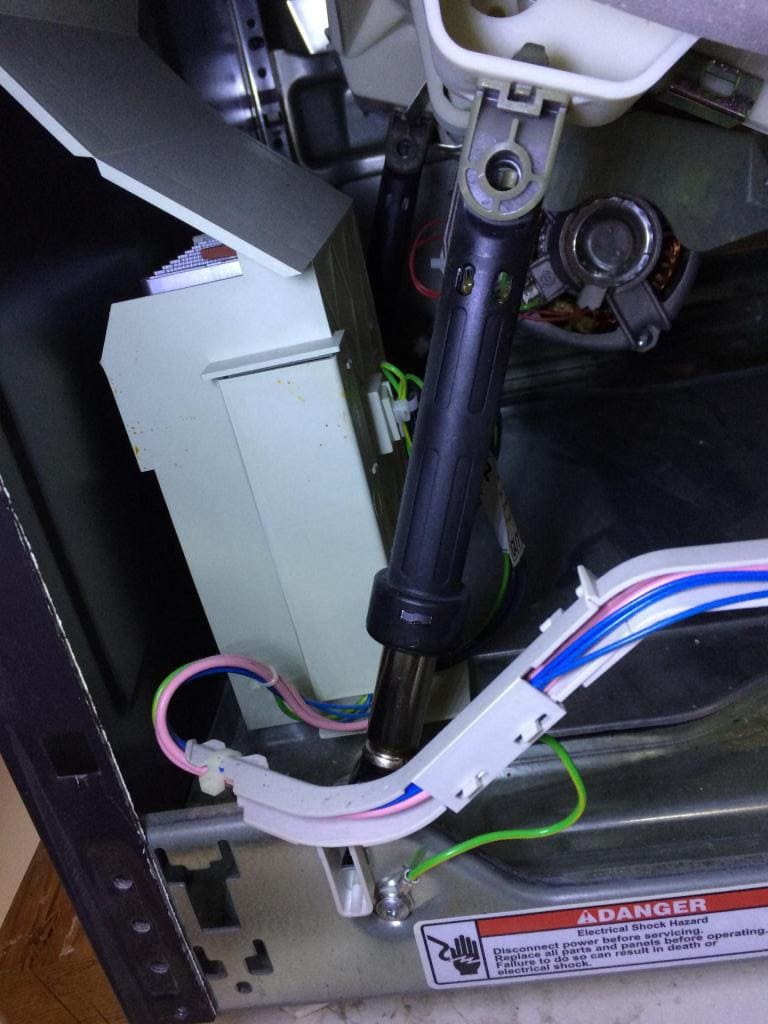

Shock absorbers (dampers) are faulty

The shock absorber is traditionally responsible for eliminating the significant vibrations that appear in the washing machine. This element plays a particularly important role during the spin process, when the drum rotates at maximum speed. Over time, the dampers wear out, so the washer experiences excessive vibration, extraneous noise, and knocking noises during the spin cycle. Most often we are talking about wear of the gasket that separates the piston and cylinder.

To get into this part of the machine, you will need to remove the rear panel (in some situations, the cover may be removed from the back or side). After unscrewing the nut in the lower area of the shock absorber, you can disconnect the part. The decision to repair or replace an item is made based on its condition. Sometimes it is enough to replace a gasket that has worn out, and in some situations it is impossible to do without completely replacing the mechanism.

To check the functionality of the damper, it must be removed from the body part by unscrewing the bolt from below, and then pressed so that the mechanism first compresses and then unclenches. If the result is almost invisible, the device is in perfect order. If the position of the piston changes easily enough, the damper needs to be replaced. Removing it from the body occurs in the same way as in the case of conventional shock absorbers.

The washing machine is leaking

If leaks regularly appear in the device, this indicates a hole in the cuff, which is the sealing element for the hatch. If there is no damage to the cuff, but water is leaking, it is necessary to clean the lower area of the glass from the inside. During operation, a huge amount of dirt accumulates in it, which leads to deterioration of contact between the glass and the sealing element. In order to eliminate this problem, you need to wipe the glass with a cotton swab dipped in acetone. Washing units belonging to the WISL series are equipped with additional protection against liquid leakage.

Problems with draining water

This difficulty occurs quite often, since the pump is the most vulnerable point of the SMA. If the problem is not corrected immediately, the system may become clogged and the impeller may become jammed.The pump is located behind the drain filter, which must be unscrewed and then removed. The impeller blades need to be tested for rotation. It shouldn't happen too easily. In its natural state, the impeller rotates well, but there are certain delays.

It also happens that the plastic body is deformed and the blades are pinched in it. If replacement options are not available, you need to trim them slightly using a knife to 2 mm, after which you can continue to use the washer. If the functioning is poor, the breakdown is more significant and cannot be avoided without inspection by a professional.

You can do it yourself by disassembling the pump. To do this, you need to lay the machine on its side, and then unscrew the screws securing the pump to the body to disconnect the electrical wires and hoses. If necessary, all these elements are cleaned. Subsequently, the engine is disconnected from the housing part, the rotor is removed from the stator. Most likely, a lot of dirt will accumulate inside, which will interfere with the rotation of the rotor. In this situation, flushing is necessary.

As for the bearing, it must be lubricated with lithol, and the seal must be adjusted. The further assembly process occurs using sealing material to avoid leaks. If you follow the operating instructions for the SMA and clean the drain system every six months, this system will not break down, at least the risks will be minimal.

The washing machine does not fill (does not fill) water well

If there are problems with the water supply, you need to check the pressure in the tap. If everything is fine with it, you will need to inspect the inlet hose and filter:

- If the water is pouring in slowly, this may indicate a blockage in the filter system in the area of the inlet valve. All you need to do is turn the washing machine away from the wall, and then unscrew the drain hose. Using pliers, you need to pull out the filter and wash it thoroughly. If necessary, you should use a brush.

If the water does not pour in at all, you need to check such aspects as the connection of the hose to the tap, the hose itself for kinks and constrictions, the water pressure in the tap area. It is important to pay attention to the open or closed position of the liquid supply tap, as well as the fact that the "Start" button is pressed. If a blockage occurs, you need to shut off the liquid supply, unscrew the hose and direct it to the basin area, and then resume the water supply process.

If none of the options are suitable, you should contact the service center.

Control module failure

The main faults in this case are such things as complete burnout of electronic elements. These, in turn, include resistors, a microprocessor, and capacitors. The problem is observed due to voltage surges and short circuits. The reason is increased humidity or water getting into the board area. Sometimes it can be a manufacturing defect.

Because this unit breaks down, the machine stops responding to pressing buttons in the control panel area. The modes do not work correctly, and error codes with the letter F appear on the display. Each of them characterizes a malfunction in the area of a specific unit. Decoding is only available when using a special table, which is indicated in the device's user manual.If the water is not pouring in well, this may indicate a blockage in the filter system in the area of the fill valve. All you need to do is turn the washer away from the wall, and then unscrew the drain hose. Using pliers, you need to pull out the filter and wash it thoroughly. If necessary, you should use a brush.

If water does not fill in at all, you need to check such aspects as the connection of the hose to the faucet, the hose itself for kinks and pinches, and the water pressure in the area of the faucet. It is important to pay attention to the open or closed position of the liquid supply valve, as well as the fact that the “Start” button is pressed. If a blockage occurs, you need to turn off the liquid supply, unscrew the hose and direct it to the pelvic area, and then resume the water supply process.

- If none of the options are suitable, you should contact the service center.

- Control module failure

- The main faults in this case are such things as complete burnout of electronic elements. These, in turn, include resistors, a microprocessor, and capacitors. The problem is observed due to voltage surges and short circuits. The reason is an increased level of humidity or water entering the board area. Sometimes it may be a manufacturing defect.

Due to the fact that this unit breaks down, the machine stops responding to pressing buttons in the control panel area. The modes do not work correctly, and error codes with the letter F appear on the display. Each of them characterizes a malfunction in the area of a specific node. Decryption is only available when using a special table, which is indicated in the device manual.

Repair of this unit is not carried out independently, because... Soldering work and ownership of a soldering station will be required. Also, only a specialist in the field of radio electronics can take on the organization of events.

Washing powder is not completely washed out of the tray

- There are several reasons why washing powder remains in the tray:

- lack of sufficient pressure supply to the tray area, the problem can be solved by repairing or replacing the solenoid valve, as well as cleaning the filter device;

- an impressive amount of powder that is poured into the tray, in this case strict adherence to its volume is required depending on the selected washing mode;

- failure of the electronic control module - this problem can only be solved using the knowledge and hands of a qualified technician.

- Sometimes the reason is the use of low-quality detergent or expired chemicals.

- Bearing failure

- If during the spin process the washing machine makes strange sounds, vibrates or hums, this means an urgent need to replace the bearing. The procedure for this is as follows:

- unscrewing two screws, sliding the cover from above (towards the front), removing the element from the washing machine body;

- disconnecting connectors from the module, latches, and then removing them from the unit;

- removal of a flexible cuff made of rubber, a panel located in front (cover), pipes with a hose, and a powder receptacle;

- unscrewing the counterweights located in front and above;

- removing the drive belt, disconnecting the wires providing power;

- removing the bottom of the device, to do this you need to lay it on its side;

- dismantling shock absorbers;

- disconnecting the springs and nuts that secure the pulley in the area of the drum shaft;

- sawing the tank directly along the seam; to solve this problem it is customary to use a hacksaw;

removal of the drum element from the tank, oil seals and, finally, bearings that have failed;

cleaning seats from dirt;

inserting new elements into the bushing and driving them into the landing zones;

closing the replaced parts with new seals;

inserting the shaft into bearings;

connecting the tank using bolts and sealed material;

installing the tank in the reverse order of dismantling.

- This process implies the need to follow an algorithm of actions.

- UBL breakdown

- If the hatch lock malfunctions, this can lead to another problem: the washing machine will simply stop turning on. The locking device also contains contacts, and when there is interference with closing, electrical energy does not flow to them. Most often, failure occurs when a large amount of dirt accumulates in the lock area. If you eliminate it correctly, the operation of the device will be restored, and this will happen quite quickly.

- The drive belt has failed

- This malfunction occurs quite often and can be fixed by yourself. To do this, you need to remove the existing belt and put a new unit in its place. Subsequently, it is enough to simply ensure that the replaced drive belt does not fail. Of course, proper operation of the washing device plays an important role, which will extend its service life and make it more efficient.

Other malfunctions of the Indesit washing machine

- Along with the above breakdowns, other problems often occur in practice:

- failure to turn on the rinse or spin mode (the problem may be in the buttons or the “insides” of the mechanism, you need to check them one by one);

- If the pump fails, it means that it needs to be replaced, because... It is extremely rare for a part to be repaired (at least sometimes it is more expedient to replace it);

- problems with the motor shaft tachometer (although the motors of these washing machines work quite well, this part fails quite often and needs to be replaced);

- malfunction of the FPS - network interference filter, which is needed to protect the unit from voltage surges and short circuits; traditionally, failure is observed due to high humidity;

failure of the mode switch (most often it turns freely, and this is a mechanical failure; it can be eliminated by repairing or replacing parts).

All these malfunctions are elementary, and even a non-professional owner of the unit can cope with their elimination. However, it is recommended to adhere to a certain algorithm of actions to avoid making mistakes:

Before loading the unit with laundry, you need to check the drum to ensure it rotates easily. The condition of the drain pump impeller and the visual integrity of the cable also play a role.

After the machine is connected to the network, you need to set a specific mode. During the operation of the program, careful monitoring of the operation of the device is required, the duration of all stages (washing, rinsing, spinning and draining) is checked. Paying attention to extraneous sounds, if any, plays an important role.

If any deviation from the norm is detected, you need to be wary. The first step is to remove the control module and take it to a specialized service for diagnostics. After this, a decision is made on the need to repair/replace parts. Some breakdowns, as already noted, can be repaired yourself.

- If there are unnatural extraneous sounds, after the process is completed, the housing casing is removed. Then an independent inspection of parts such as the drain pump, electric motor, bearings, i.e. is carried out. the most frequently broken spare parts.

- If we are talking about leaks, it is necessary to check such important elements as the cuff, powder receptacle, drain and supply pipes, and outlet hose. Most likely, this is precisely the problem, and only with timely repairs will the result not be long in coming.

- Thus, the number of breakdowns in SMA Indesit is quite large, and they occur with the same frequency, regardless of the model. Some faults can be fixed on your own, while in some situations you cannot do without professional repairs.

- Tips for repairing Indesit washing machines

- In the process of finding out the reasons why the breakdown occurred, you should not get involved in something that you do not have a basic understanding of. For example, you can independently eliminate problems in the electronic board, change bearings or disassemble the motor. Basic problems can be eliminated without the help of a specialist. Especially when it comes to leaks, insufficient supply of powder and water.

- If a puddle constantly appears under the device, it may be necessary to check and then replace the rubber parts. These are pipes, cuffs. Minor breakdowns also include work to replace the belt.In other cases, you need to contact a service center so that diagnostics and repairs can be carried out by specialists.

In general, the device of this device is simple, and it allows partial or complete disassembly in order to diagnose parts that have failed. The order of the events is as follows:

- disconnecting the unit from the network;

- turning it away from the wall;

unscrewing the screws from the end of the cover located on top;

shifting the cover horizontally (to do this, you need to lightly press on it);

slow panel lift;

removing a part that is broken and replacing it.

Errors E1 and 4C on a Samsung washing machine