Household appliances make life much easier. For example, almost every family has a washing machine. She has ceased to be an inaccessible item, and has now become an indispensable assistant to any housewife. Any equipment fails sooner or later, and a washing machine is no exception. No matter how expensive and high-quality a model is, it is not immune to malfunctions.

When the washing machine breaks down, the question immediately arises: what to do? If the warranty period for the machine has not yet expired, then it is better to contact a specialist to solve the problem. If the warranty has expired, then to save money you can fix the problem yourself. Repairing a washing machine with your own hands is not difficult, you just need to have an idea of how the washing device works, as well as the algorithm for its operation.Most breakdowns can be fixed on your own, without the help of equipment repair workshop workers, you just need to study this issue a little.

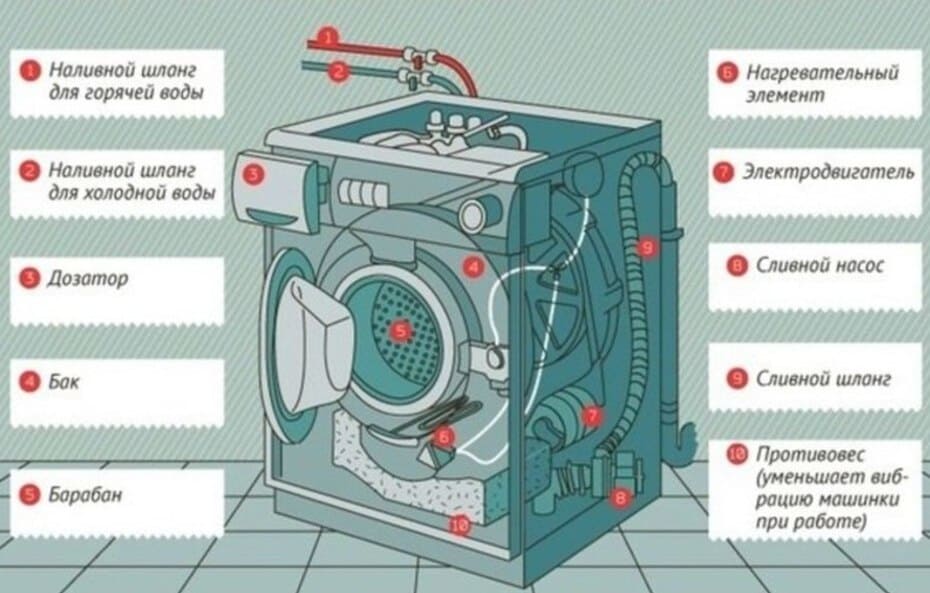

Design and principle of operation of an automatic washing machine

Regardless of the manufacturer, all machines have a similar structure and operating principle. They differ only in the volume and type of loading. All machines have a control unit. It includes panel and board. The control panel contains buttons and levers with which the operating mode is set. The board recognizes these modes and sends signals further. With the help of these signals, water is drawn in, drained, heated, and the drum is also set in motion.

Each process is monitored by a variety of sensors. They send information to a microprocessor located on the board. The machines contain sensors such as:

- sensor responsible for water level. Monitors the volume of water in the device. Gives a signal to turn on/off the water supply;

- sensor responsible for heating water. Gives a signal to turn on/off water heating;

- tachometer Responsible for the speed at which the drum rotates;

- time relay. Responsible for the amount of time spent on different stages of washing.

The main sign of a control board malfunction is a failure in the programs. Basically, the board is not repaired, but replaced, after which the machine works properly again. The board is attached to each actuator: drum, pump, electric motor, valve that shuts off the water pressure, etc. The main actuators include the following:

- loading hatch door lock. If the door is not closed tightly, the machine will not start the wash.It is necessary to press a little on the door so that the contacts close, after which the washing starts;

- water supply valve. The washing device is connected to the central water supply using a hose. There is a valve in it, it starts and turns off the supply of water to the device. If the machine does not start drawing water or does not stop drawing water, then the valve is broken. It should be cleaned of dirt or replaced;

- electric motor Thanks to the motor, the drum moves during washing. There are models of machines where the movement of the drum is transmitted to a pulley through a belt, and there are devices with direct drive. When the drum stops rotating, the belt is replaced. If the drum stops rotating on a device with a direct motor, then the fault will be in the electric motor;

- TEN (tubular heating element). Thanks to this part, the water can be heated. If the water stops heating, then the heating element is faulty. If it is working properly, then look at the condition of the temperature sensors;

- water pump. It is a pump that pumps out waste water after the end of the washing cycle.

The main part of the body is allocated for the tank in the washing device. It contains a drum, a heating element and several sensors. The tank includes two parts that are connected to each other. Water is collected and pumped out through special tubes that are connected to the walls of the tank. The top of the tank is attached to the body of the machine using springs, and the bottom using shock absorbers. This fastening helps reduce the level of vibration that occurs during washing.

There are models with collapsible and non-removable tanks. The first option is more expensive, but they are easier to repair with your own hands.If any part located inside the tank breaks, it can be easily replaced. To do this, you just need to disassemble the tank of the machine. In another case, you will have to replace the faulty part along with the tank.

All washing devices, regardless of manufacturer, operate according to the same scheme. The washing process consists of the following steps:

- You need to turn on the washing machine, place the laundry inside, and select a washing program. After this, a mechanism will work, which will lock the door and start the wash.

- Water begins to flow through the hose through the valve, the valve will adjust the amount of water and stop drawing it.

- Once the required amount of water has been collected, the valve will close.

- Then the heating element will start, it will heat the water to the required level. The sensor is also responsible for heating the water, but if it is missing, the timer will work.

- Together with the heating element, the electric motor also starts working. It starts the drum, which rotates smoothly from side to side at regular intervals. This helps wet the laundry.

- After heating the water, the heating element will turn off and a full wash will start. The drum will begin to rotate smoothly from side to side at regular intervals. This process prevents the laundry from bunching up.

- At the end of the wash cycle, the used water will be drained away. New water will begin to rinse the laundry.

- After this, the drum will begin to rotate slowly. You can select different modes, the number of starts of the rinsing process will depend on this.

- After the last rinse, the pump comes into play again and pumps water out of the drum.

- Then the drum will begin to rotate at high speeds. This will start the spinning process.All this time the pump will continue to operate.

After this, the machine turns off, and the washing cycle can be considered complete. There is nothing unclear about the design and operation of washing machines. You should know all this in order to understand at what stage of washing the problem occurred and which part is responsible for this stage of washing. Knowing all this, you can easily replace the faulty part. Since all washing devices are similar, the problems leading to breakdowns will be the same in them.

Wash does not turn on

The most common malfunction that owners of washing devices encounter is that when the start button is pressed, the machine does not start washing. If the indicators on the control panel do not light up, then the problem lies in the power supply. It's worth doing the following:

1. Check the connection of the machine to the power supply; sometimes owners simply forget to plug the device into the outlet.

2. Check how tightly the loading hatch door is closed. Until the lock on the door works, the washing will not start. Press down on the door and see if there is a foreign object in the lock that prevents reliable closure.

3. If the above does not work, the voltage may be too low. It is worth checking the electrical panel to see if the plugs have been knocked out due to overload.

4. Check if the socket is working properly. Check the serviceability of the plug; you can unscrew it to eliminate the possibility of contact oxidation. If these parts are ok, then move on to the next one.

5. Check the serviceability of the cord; perhaps it is bent or torn somewhere. Also check the condition of the cord located in the terminal block.To do this, you need to remove the outer cover of the washing machine. Find this block and check the condition of the contacts; if necessary, the contacts should be cleaned.

6. Another reason for poor performance is the time relay. Start switching different washing programs; if the washing starts in an instant, it means that the time relay is actually faulty. In this situation, the repair consists of replacing this part.

7. See if the inlet valve is open. If it turns out that it is not open, then it will need to be opened, after which water will begin to flow into the device, after which the washing cycle will start.

If all the methods described above did not prove effective, then the fault will be in the control board. You can find out for yourself whether this is true or not only by replacing the board with a working part. But it is safer to seek help from a workshop, because a professional will be better able to replace the control board.

The washing machine does not fill with water

There are several reasons why the washing device does not draw water. Main reasons:

- there is no water in the central water supply. If there is water, then unscrew the tap and see if the pressure is sufficient;

- see if the valve that allows water to fill is unscrewed;

- It is worth looking at the hose through which the water flows. Probably, a blockage has formed in it, or it has been crushed. The blockage should be cleared and the hose straightened;

- clogged intake filter. To correct this situation, turn off the water. Then separate the hose from the washer, remove the filter and rinse it. Assemble the structure;

- intake valve failure.To correct the situation, you need to do the following: turn off the water supply and replace the inlet valve with a working part;

- The sensor that controls the water level is broken. As the water level in the machine increases, the displaced air begins to put pressure on the pressure sensor, which causes the switch to be activated. If this system becomes clogged or becomes unusable, water will stop flowing into the device.

The problems listed above can lead not only to the fact that water has stopped collecting. This can also lead to water taking a very long time to accumulate. The algorithm of actions will be the same. If in case of a breakdown none of the above methods help, then the cause of the malfunction will be the control unit. It is better not to solve this problem on your own, but to seek help from a specialist.

The water in the machine drum does not heat up

It is very easy to determine that the water has stopped heating. If at the time of washing the glass of the loading hatch door remains cold, it means that the water has stopped heating. There are various reasons for this fault to occur. The main reasons are the following:

- The sensor responsible for the water level is broken. The heating element starts only when the sensor reports that there is a sufficient amount of water in the tank. This cannot happen if the sensor is faulty. To correct this situation, you need to replace the faulty sensor. The lid of the washing machine should be removed. Find this sensor, it is a small box located on the side wall. Unscrew the bolts that hold the sensor and remove the tube. Take a tube with the same diameter as the one you removed and about 20 cm long.Place one end of this tube on the fitting, and on the other side you need to blow into it. If a click is heard during this process, then the sensor is working. Place the working sensor in its place;

- oxidation of heating element contacts. To correct the situation, you should clean the contacts;

- The thermostat has failed. The thermal relay is located under the loading hatch. Having taken out this sensor, you should check its functionality. It is necessary to measure the resistance of the thermal relay in a cold state. Then you need to hold it near boiling water for 2-3 minutes and measure the resistance again. If the difference is too obvious, it means that the thermal relay is working properly. If practically nothing has changed, this means that the thermal relay needs to be replaced.

Also, the cause of the breakdown is that the heating element has burned out. In this case, it will need to be replaced with a working part. If the water heats up extremely slowly, it means that scale has appeared on the heating element. It will need to be removed from the machine and descaled.

Water leaks from the washing machine

There are various reasons why water leaks out from under the machine during the washing process. First, you should pour out the remaining water, after which you can begin diagnostics. You need to check the following points:

- make sure that the sewer hose has not come off. Check if the pipes are clogged;

- inspect the place where the outlet hose is attached to the washing device. It attaches to the pump, so it takes a little effort to reach it. In some models, the pump is located at the bottom of the machine; you will need to turn the washing machine over. If the hose begins to leak at the connection point, it is necessary to loosen the clamp, move the hose forward a little and tighten the clamp.In other models, this pump is located inside, so you will need to disassemble the device body. You will need to get to the drain hose and do similar manipulations;

- replace the drain hose. This manipulation is necessary if the drain hose is cracked or frayed. You need to get to this hose and disconnect it. After this, place a new hose in this place and assemble the device.

If water seeps out from under the closed loading door, the elastic lining has worn out. It needs to be replaced with a new one.

The machine does not drain dirty water

The drain pump is responsible for draining used water from the drum. There are many possible faults. The main reasons are as follows:

- the drain hose is pinched;

- Sometimes the indicators light up properly, but the washing machine does not start draining. The reason may be the inattention of the housewife who pressed the “Stop” button, thereby stopping the washing;

- problem with the water level sensor. The algorithm of actions will be the same as if the water stops heating;

- The filter in the outlet pipe is clogged. It is located on the lower right side of the device. The filter needs to be unscrewed, washed and put back;

- The pump has a filter that can trap a variety of small objects. If the filter becomes clogged, it needs to be removed and cleaned, and then put back.

A broken pump may also be the cause of the breakdown. It is difficult to repair the pump yourself, so it is better to seek the help of specialists. You can change the pump yourself.

The drum of the machine does not spin

There can be many reasons why the drum stops rotating during washing. Main reasons:

- The drive belt may come off, loosen or break - this is the most common cause of the problem. You need to check the tension by pressing on the belt. If it sags by more than 12 mm, then that is the problem. If the washing device has a tensioner, the belt should be adjusted. Otherwise, it must be changed;

- Something may become clogged in the connector between the tank and the drum, which will prevent the drum from moving. The drum should be untwisted and diagnostics carried out;

- the electric motor burned out. This is the most serious problem. Check if there is voltage at the terminals. If it is missing, then the electric motor is broken.

Only a professional can repair a faulty electric motor, and you can only replace it yourself.

The washing machine vibrates strongly

As a rule, owners encounter this situation at the spinning stage. The washing machine begins to vibrate, make strange sounds and bounce. The most common and banal reason is that the drum of the washing device is overloaded with laundry. Or there may be the opposite situation, when there is not enough laundry and it gathers in a lump. To solve the problem, you need to stop the wash and in the first situation take out some of the clothes, and in the second, distribute them evenly throughout the drum. After this, start the wash again.

If vibration is observed constantly, then the reasons may be hidden in broken suspension springs, failure of shock absorbers, or loose ballast fastenings. It is not difficult to correct the situation yourself. When the ballast becomes loose, the bolts must be tightened. If the suspension or shock absorbers are faulty, they must be replaced.

The washing unit does not spin clothes

Spinning is what any wash ends with. But sometimes the machine stops spinning. This can happen for various reasons. The main reasons are as follows:

- an error in the washing program. When washing some types of fabric, spinning is not available by default;

- the laundry is not evenly distributed in the drum, which is why it does not move;

- the pump is faulty, so the water does not drain, and the machine cannot switch to spin mode;

- the tacho sensor is faulty;

- a malfunction with the electric motor.

The most common reason is the formation of a blockage in the drainage system. To eliminate this problem, you need to clean the filter, and also remove all small objects that have clogged it.

Whatever the reason for the breakdown, first you should disconnect the washing machine from the power supply, manually drain the water from the tank. Only after these actions can you begin to look for the cause of the breakdown.

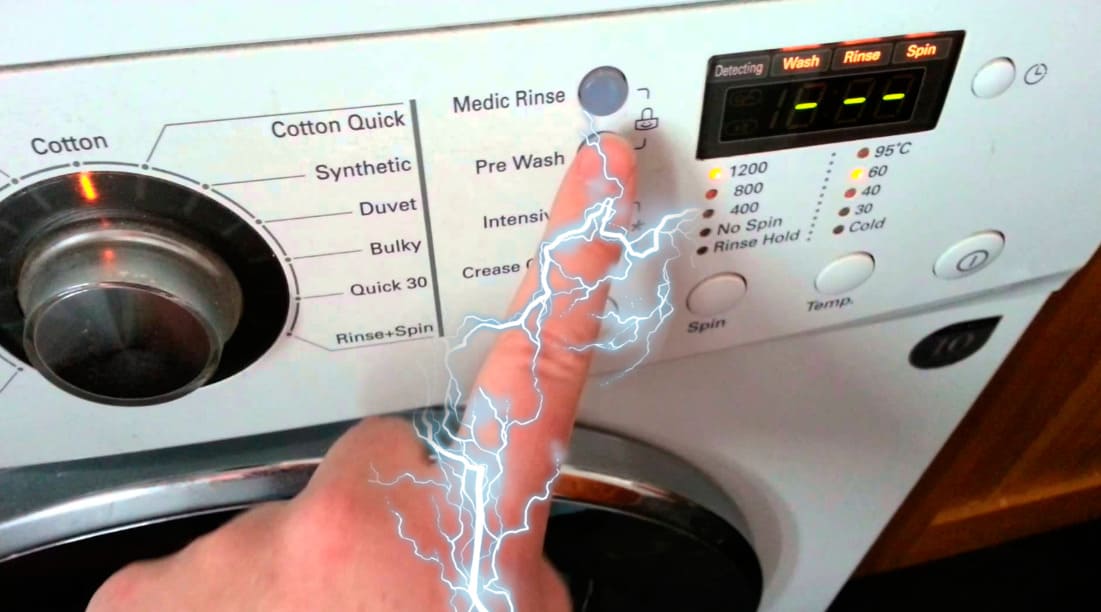

The washing machine gives an electric shock

This is not the worst problem, but it can cause significant inconvenience to the owners of the washing machine. The washing machine is an electrical household appliance, so when installing it, you should take care of grounding. The cause of the malfunction is also the electrical wiring. If everything is in order with it, then the reasons may be a torn or frayed wire, a breakdown in the heating element or electric motor. It is necessary to find and fix the breakdown as quickly as possible, because using such a unit can be dangerous for the owner.

- The loading hatch of the machine does not open

- There are many reasons why the loading hatch stops opening. The main reasons:

- the washing process has not finished.Spinning clothes is what ends every wash. But sometimes the machine stops squeezing things out. This can happen for various reasons. The main reasons are as follows:

error in the washing program. When washing some types of fabric, there is no spin by default;

the laundry is unevenly distributed throughout the drum, which is why it does not move;

the pump is faulty, so the water does not drain, and the machine cannot switch to spin mode;

tachometer is faulty;

malfunction with the electric motor.

- The most common cause is the formation of a blockage in the drain system. To fix this problem, you need to clean the filter and also remove all small objects that are clogged in it.

- Whatever the reason for the breakdown, you should first disconnect the washing device from the power supply and manually empty the water from the tank. Only after these steps can you begin to search for the cause of the breakdown.

- The washing machine is electrocuted

- This is not the worst problem, but it can cause significant inconvenience for washing machine owners. A washing machine is an electrical household appliance, so when installing it, you should take care of grounding. The cause of the malfunction is also the electrical wiring. If everything is in order with it, then the reasons may be a broken or frayed wire, a breakdown in the heating element or electric motor. It is necessary to find and fix the breakdown as quickly as possible, because using such a unit can be dangerous for the owner.

- The loading hatch of the machine does not open

- There are many reasons why the loading hatch stops opening. Main reasons:

The washing process has not finished.The drum is probably still rotating, so you need to wait a couple of minutes before the door can be opened;

there is water in the tank. The drain filter may become clogged. It should be cleaned. But first, you need to pump out the water yourself, and the door will open;

The door lock or handle is broken. They will need to be replaced;

- The loading hatch lock switch is broken. It must be replaced.

- In addition, a software glitch is also a cause of failure. To solve the problem, unplug the washing device from the outlet for a few minutes and then try to open the door.

- Do-it-yourself washing machine repair

- In order to repair a faulty washing machine with your own hands, you need minimal knowledge of how to handle tools. Before proceeding directly to repair work, you should carefully study the work plan. This will avoid errors that may occur during the process and bring a faulty washing machine back to life.

- Bearing replacement

As a rule, replacing the bearing is necessary when unusual sounds and vibration appear during spinning. To correct this situation, the bearing must be replaced. The bearing replacement process consists of the following steps:

Remove the back panel of the device case.

Clear the path to the bearings by removing the belt from the pulley.

Unscrew the bolt that attaches the pulley to the drum, then remove the pulley.

Unscrew the screws that hold the structure, then remove the coupling with bearings.

Remove the O-ring and seal. The latter will also need to be replaced.

- Reinstall new, serviceable parts.

- This completes the bearing replacement, all that remains is to assemble the washing machine.This must be done using these instructions, but only from the end.

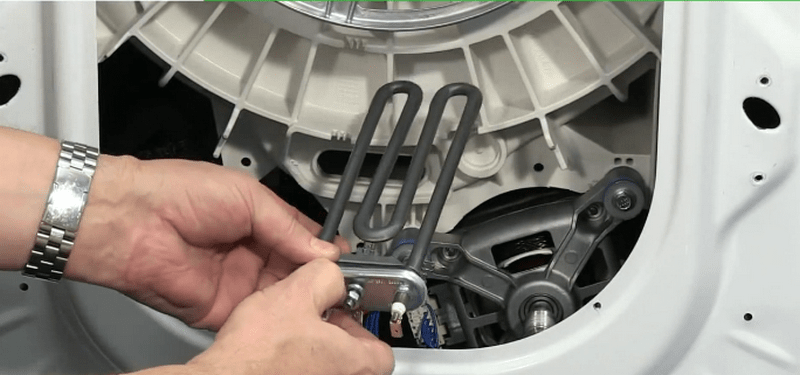

- Replacing the heating element

- The heating element can often turn out to be faulty. The reasons for this are different: the pipes are covered with a layer of scale due to frequent contact with water, the heating element burns out due to prolonged use or surge voltage in the electrical networks. Regardless of the reason, the heating element will need to be replaced. You can do this action yourself. Replacing the heating element includes the following steps:

- In almost all washing machine models, this part is located on the rear panel of the case, so you need to remove the rear panel.

- Remove the terminals for connecting the electrical appliance.

Unscrew the nut with a wrench, then press on the stud with a screwdriver. Unscrew the faulty heating element from the seal.

Place the new part in place.

Reassemble the devices in reverse order.

- To avoid confusing anything during assembly, you can take a photo of how all the elements and wires were located. This will help avoid mistakes.

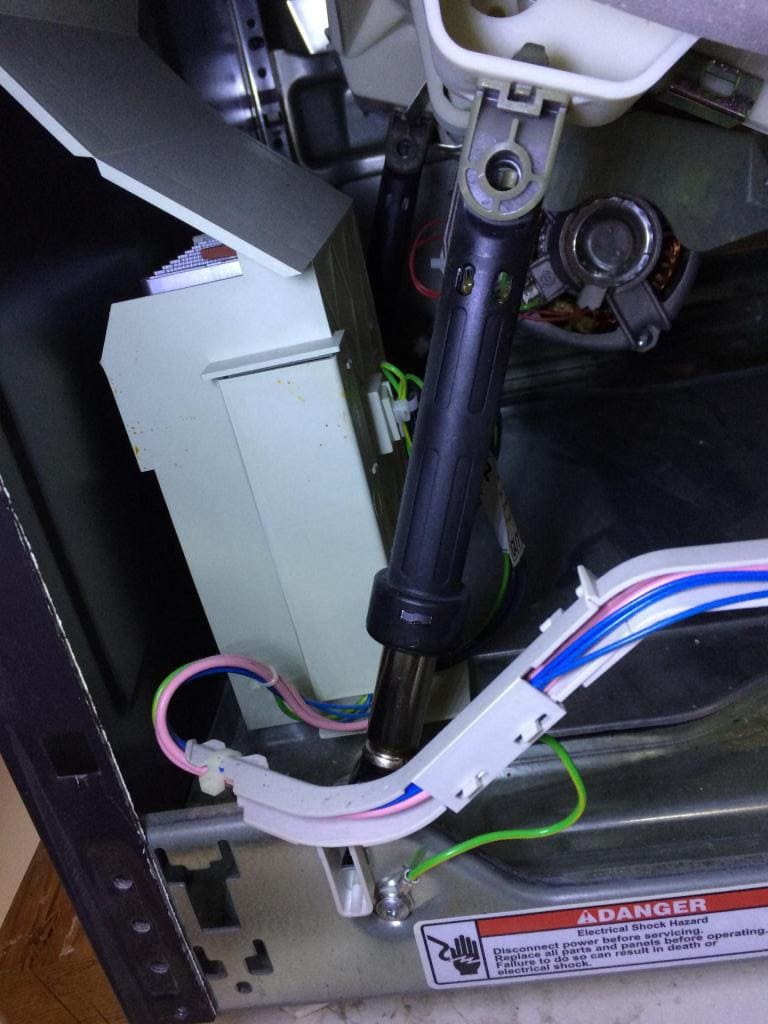

- Replacing shock absorbers and dampers

- These elements in the washing device serve to protect parts of the washing machine from excessive vibration and premature wear. But, despite the fact that these parts perform the protective function of other parts, these parts themselves are subject to fairly rapid wear. Therefore, you can often encounter a situation where it is necessary to replace the shock absorber and damper.

- If the dampers fail, then it will be enough to replace the seal in them. With shock absorbers the situation is different. Replacement requires complete disassembly of the washing machine body. It is very difficult to do this on your own; there is a high chance of damaging something, so it is better not to risk it, but to contact a service center for help.

- Cleaning filters

- This procedure is not only a repair, but also a preventive maintenance of the pump. A lot of small debris can become clogged in the filter, causing the pump to stop pumping out dirty water. To prevent this from happening, it is necessary to periodically clean the filters. This process is the simplest thing a washing machine owner can do. The filter cleaning process consists of the following steps:

Open the small door located at the bottom of the device. If it does not give in, you can lightly pry it up with a screwdriver.

Unscrew the plug.