Laundry washing units are distinguished by their quality, technology and functionality. But even the Hansa machine has weak points, which are manifested by certain malfunctions caused by improper operation, manufacturing defects and other reasons. This article will tell you how to repair a Hansa washing machine yourself.

Laundry washing units are distinguished by their quality, technology and functionality. But even the Hansa machine has weak points, which are manifested by certain malfunctions caused by improper operation, manufacturing defects and other reasons. This article will tell you how to repair a Hansa washing machine yourself.

Main malfunctions of Hansa washing machines

Consumers hardly complain about washing machines produced under this brand, and there are certain reasons for this. The models are not very common, if you compare them with Indesit, Ariston, Samsung, they appeared on the Russian markets not so long ago, they are of good quality. A pattern even emerges - if everyone has such models, then repair of Hansa washing machines will become a more frequent occurrence.

Today it is possible to talk about the most frequent failures of Hans washing units, using rather meager statistical data provided by large repair service centers. After analyzing this information, we identified the vulnerabilities of machines from this manufacturer:

- Quite often the pump responsible for draining the water fails;

- the filter and drain pipes become clogged;

- The AQUA-Spray system breaks down;

- short circuits occur in the temperature sensor;

- The machine often freezes due to a voltage drop in the electrical network.

Very rarely, but there are problems with the electronic control and the system that protects against water leakage.

Hansa washing machine repair

In certain situations, it is quite possible to eliminate a machine failure with your own hands.

- Filter clogged, pump failure.

The first place in the rating of malfunctions of these machines belongs to the filter and hose clogged with debris. There is nothing strange about this, since this reason actually most often occurs in automatic and semi-automatic washing machines. In such a situation, there is no need to call a specialist - everything can be fixed yourself.

Cleaning the filter is an easy process, which is described in detail in the operating instructions. Removing a blockage in the hose will not cause any difficulties, but you will have to tinker with its installation/disassembly. In order to unscrew the drain hose, you will have to climb into the unit body:

- you need to unscrew the back panel;

- find the connecting clamps for the hose and pump and release them;

- disconnect the drain hose, rinse it, clean it with a cable;

- Connect and reassemble in reverse order.

Remember that the hose should be cleaned, even for preventive purposes, once a year.

But the pump in a machine of this brand breaks down quite unusually:

- the machine starts to freeze from time to time, the water does not drain, but when a reboot is performed, everything starts working normally;

- After a certain time, freezing becomes more common, especially after washing with hot water. Restarting the program does not solve the problem, but when the water cools down, the machine continues to work normally;

- Such problems arise for quite a long time, then the washing machine completely stops draining water.

What conclusions can be drawn from such symptoms? Most likely, the impeller on the pump has failed, and repairs are required. Such work is quite feasible for every consumer, if all the recommendations of professional specialists are followed precisely. The list of works is as follows:

- First, the water is drained, for which it is necessary to unscrew the drain plug, placing a container under the machine;

- Remove the detergent tray;

- Turn the washing machine on its side;

- Unscrew the bottom, if any;

- Disconnect all wiring from the pump;

- Remove the impeller, check the pump for clogging;

- Install a new impeller;

- Connect the wiring, tighten the fasteners, place the machine on its legs, connect to the utilities and check for serviceability.

- Heating element failure.

Tubular heating elements fail quite often. This may be caused by voltage surges in the electrical network. The element fails due to a short circuit. In addition, due to the hardness of the water, scale forms on the heating element, it overheats and burns out.

You can determine the breakdown of the heater by external signs. If after turning on the machine the circuit breaker in the panel is de-energized, the fuse burns out - look for the problem in the heating element. The second sign is that things are not washed well, there is a musty smell, since the water does not heat up.

To replace the heating element, you will have to remove the front wall and do the following:

- at the base of the drum we find the heating element;

- disconnect all the wires;

- loosen the nut located in the center, push it inward, squeezing out the gasket;

- remove the heating element, install a new analog in its place.

- Failure of the Aqua-Spray system.

Often, problems appear in such a machine in which they do not pump water into the tank, as a result of which the washing process does not start, and error code E 05 lights up on the screen. In this case, you need to start checking with the inlet valve, since it is responsible for pumping water . Having removed the top panel, we check the valve and measure the resistance values using a multimeter. If everything is in order, we move on to the AQUA-SPRAY system, which runs from the inlet valve to the tank. With its help, water flows over the laundry in strong jets, which makes stain removal more efficient. The disadvantage of the system is the complex and sometimes thin path for supplying liquid, which can quickly become clogged with salts and metals in the water. What to do in such a situation?

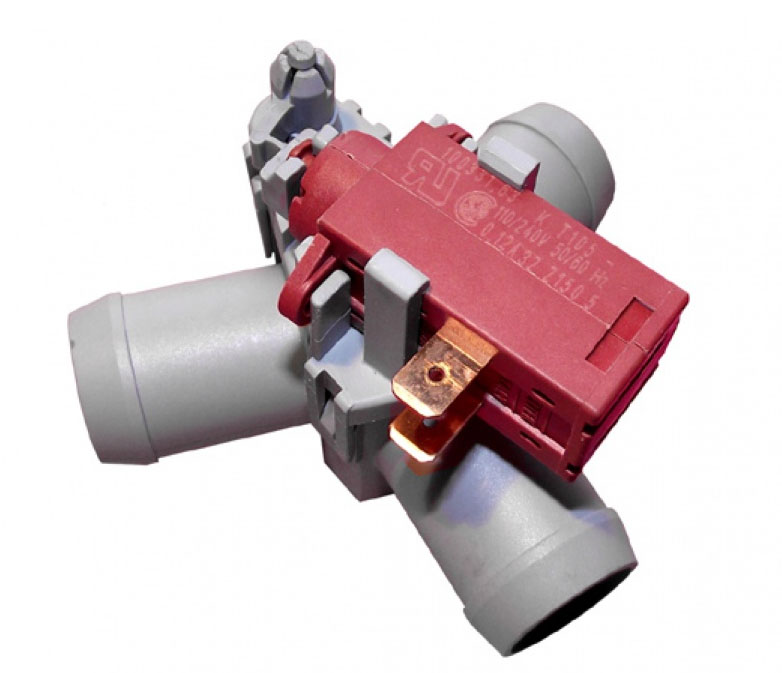

Hansa aqua spray switch valve

Necessary:

- find the path of this system near the intake valve;

- remove the plugs;

- take a bottle of water, pour it into the tract, check how well it goes into the tank;

- If a blockage is detected, use a thin wire to clean the tract, pouring warm water into it from time to time. It would be nice if you first dissolve citric acid in it;

- When the water begins to flow through without interference, the machine can be assembled and a test run can be carried out.

- Problems with the electrical network.

Most models of washing machines have a protection system against power surges. The protection is intended to preserve the unit responsible for control if a short circuit or other electrical problems occur. It was initially well conceived, but the quality of execution was not up to par.

The machine still retained sensitivity to voltage changes in the Russian electrical network. In the best case, it stops the work program or simply turns off.But only a specialist can restore its functionality. In such situations, performing repair work on your own is strictly contraindicated. But you can avoid such troubles in the future by connecting the washing machine through a stabilizing device.

- Bearing wear.

You can recognize this problem by the characteristic grinding noise that occurs during washing. Replacing the bearings in the machine is difficult, but you can do this work yourself:

- remove the top panel;

- unscrew the fasteners, remove the counterweights in the front and on the sides;

- disconnect the clamps holding the AQUA-SPRAY system path, move it away from the cuff;

- loosen the bundles, unscrew the mounting bolts, remove the electric motor;

- loosen the clamps, remove the drain pipe;

- dismantle the tank from the shock absorber elements, lay it on a flat surface. Now we have to disassemble the tank itself:

unscrew the nuts, remove the pulley;

- turn the tank over, unscrew the nuts along the entire perimeter;

- remove the lid, push the bolt inward, pull out the drum.

- It remains to take out the bearing and replace it. Now we assemble the unit in the reverse order and check it in operation.

Conclusion

As a result, it should be noted that there are not so many weak points in the Hansa washing machine. But they can also manifest themselves as malfunctions at the most inopportune moment. In some situations, diagnosing such breakdowns is a rather complicated process, for this reason you will need the help of an experienced specialist from the service center.

Similar entries from this section