Failures in Ariston washing machines are rare, since the manufacturer guarantees the reliability of its product. But there are several typical cases that imply the replacement of failed elements. In such situations, repair of Ariston washing machines can be done on your own. The intervention of experienced specialists will be required only in particularly difficult cases.

Failures in Ariston washing machines are rare, since the manufacturer guarantees the reliability of its product. But there are several typical cases that imply the replacement of failed elements. In such situations, repair of Ariston washing machines can be done on your own. The intervention of experienced specialists will be required only in particularly difficult cases.

The vast majority of failures of Ariston machines are caused by their operation. This is the opinion of service technicians providing repair services. Sometimes problems are caused by obvious violations of operating rules, but you should not discount the environment in which the machine is used.

Main malfunctions of Ariston washing machines

The famous brand has found its niche in the market. But, like other models, the washing machine is prone to minor breakdowns, which most often occur due to careless handling of the device. The fact is that each element has a certain working resource. For example, the brushes of an electric motor can serve for about twelve years without replacement. During this period, they wear out and need to be replaced. The drive belt, which also needs to be changed, loses its functionality a little earlier, for which you will have to disassemble the washing machine.

For some failures, Ariston washing machines can be repaired on their own, without the intervention of service center specialists. Some of the simpler and more common failures include the following:

- the washing machine does not turn on;

- waste water is not drained;

- The washing water is not heated;

- the drum stopped rotating;

- During operation of the machine, crunching and grinding noises are heard.

For more serious issues, it is recommended to call a specialist.

Troubleshooting

The failures listed above can occur for certain reasons, which you can eliminate with your own hands.

- Blockages.

If a similar problem arises, do not rush to call a specialist. The main symptom of this problem is the pump running idle and the water not draining. Typically, this problem occurs after washing; the machine does not drain the water to switch to rinsing, or does it too slowly. A blockage can form at certain points:

- in the drain pipe located between the filter and the tank. This rarely happens because the pipe is quite thick;

- in the water drain filter. This is where blockages occur most often;

- in the pump. For a machine of this brand, blockage in this place is rare, because another filter is mounted in front of the pump;

- in the drain hose. A rare occurrence that may be caused by incorrect installation of the hose.

When clearing a blockage, you first need to inspect and clean the most accessible places in the washing machine. First of all, the drain filter, located in the lower part on the right, behind the narrow panel, is unscrewed. Before you start unscrewing the filter, you need to place a rag to catch any spilled water. After cleaning the filter from debris, you can put it back in place.

The second stage is checking the drain hose. It is unscrewed and cleaned with a cable. After this, the hose is installed in its place.

If the problem persists, you will have to disassemble the machine to clean the pump and pipes. To remove the pipes, release a pair of clamps, and when dismantling the pump, disconnect the electrical wiring and unscrew the mounting screws.

- Failure of the pump and water intake valve.

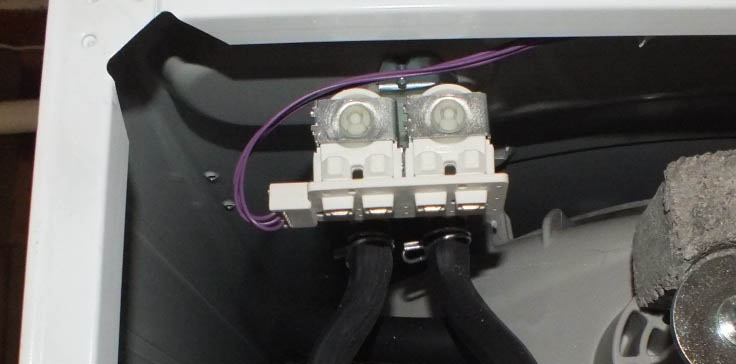

By all indications, a broken water fill valve is quite difficult to confuse with other faults of the washing machine. When this element stops blocking the flow of water, it enters the tank by gravity, even when the machine is de-energized from the electrical network.

If you hear the characteristic murmur of flowing and draining water when the unit is turned off, you can be absolutely sure that the problem lies in the valve.

To check this element, you need to remove the top panel, which requires unscrewing a couple of bolts. The valve is located at the connection point between the hose intended for collecting water and the SMA body. First you need to check the gaskets, then measure the resistance of the device using a multimeter. To do this, probes are placed on the contacts of the intake valve and a check is performed. The device should display a value of 30 - 50 Ohms.

The failed element must be replaced with an analogue; it can no longer be repaired. The replacement process is completed quite quickly. You just need to unscrew the old element and install a new one in its place, connecting all the sensors.

The problem arises with a failed pump, since such a part is quite expensive. A failed pump will give itself away during the washing process, when the unit should drain waste water, but this does not happen.In this case, no sounds are heard from the pump, or it hums idle, and the murmur of running water is not heard.

It should be noted here that such signs are considered approximate and may well confirm that there are problems of a different nature. For example, the electronics have failed. And yet, first of all, it is necessary to check the pump.

In Ariston, it is located at the bottom, you can get to it through the bottom of the machine. Checking and changing the pump should be entrusted to a master, but some craftsmen do this work themselves.

- Failure of the water heating element.

The heating element is considered an important part that is responsible for maintaining the temperature of the water in the tank, accordingly, and for the quality of the washing process. If it breaks, the wash may not start at all, an error code will appear on the screen, or the wash will start in cold water. Both phenomena should cause you to inspect the heating element, check its operability and, if necessary, replace it.

The check is quite easy. You should turn the washing machine around, find the service hatch on the back panel at the bottom, secured with clamps and screws. After unscrewing and pressing the fasteners, remove the cover. There are two contacts under the tank, secured in the middle. The screw must be unscrewed, then the heating element is carefully pulled out towards you. At this point, you can gently rock it in different directions.

It is recommended to check its resistance using a multimeter before removing the heating element.

If the heating element burns out, replace it with a similar one. Installation is performed in the reverse order.

- Bearing failure.

It is no longer a secret that failure of oil seals or bearings is a fairly rare occurrence in Ariston. But sometimes this happens, and appropriate measures must be taken immediately. Such a breakdown is recognized quite easily - after its destruction, all the rubbing elements in the bearing make unpleasant sounds, the shaft rubs against the bushing, forming a wear. If you do not take appropriate measures and continue to use the washing machine, play will appear in the drum, which will damage the tank.

To prevent the machine from breaking down completely, you should immediately call a technician when you hear such sounds, or try to replace the bearings yourself. The main difficulty is that you will have to disassemble the washing machine. The bearings must be removed so as not to damage the bushing, and new elements must be installed in the vacant space. And here proper skill will be required, otherwise the repair will not bring positive results.

- The washing machine does not turn on.

This problem can arise from a faulty socket or power supply wiring. The first option is easy to check - just turn on another electrical appliance. If it works, disconnect the wire powering the machine and check it with a tester. If the wire is in good condition, you need to look for the problem in the control unit. This is a more serious problem that requires the intervention of an experienced specialist.

- No drum rotation.

The first thing you pay attention to is the condition of the drive belt. During the operation of the machine, it is subject to severe wear and stretching. To such problems you can add a gap or enlargement, which is also not very pleasant.In each of these cases, it is necessary to replace the drive belt. Such repairs do not cause any particular difficulties; they can be carried out on their own.

It should be noted that the belt is not considered the only cause of such a failure. There may be several more troubles associated with a failure of the electric motor, a breakdown in the control unit, faulty electrical wires, or blockages in the filter. Each of them can cause the drum to stop rotating. Only an experienced master can determine it.

- Breakage of fasteners.

It may happen that the door in the machine stops closing or locking tightly. The problem should be sought in its distortion, which does not allow the hook to enter the hole intended for it. To fix this problem, you just need to tighten the door hinges. If the locking tongue wears out or the handle becomes loose, it is best to simply replace these elements.

- Repair of the control module or its replacement.

In order to remove this element, you need to perform several steps in sequence:

- it is necessary to turn off the power to the washing machine by unplugging the plug from the socket;

- remove the top panel of the machine;

- by pressing on the special latch located in the center, remove the detergent box (dispenser);

- Now the front panel is unscrewed, the clamps are released, the board is turned off;

- the selector is removed and a new board is placed on it;

- All that remains is to reassemble in the reverse order and check the machine for functionality.

Remember that there is nothing complicated here. But checking and cleaning oxidized contacts is much more difficult.

Conclusion

The manufacturers of the Ariston washing machine showed concern for the future owners of their product, providing it not only with modern functionality and beautiful design, but also with a convenient system for self-diagnosis of faults. Codes indicating malfunctions light up on the machine's display. For some models, a failure may be indicated by a blinking indicator on the panel.

Without a doubt, the Ariston washing machine has a complex structure, but most often, if you have information about errors and breakdowns, you can easily find their cause and carry out repairs on your own, without the help of qualified specialists. It is only recommended not to neglect technical advice, to comply with every last detail, and to comply with safety requirements.