Miele machines are distinguished by a unique drum design, a mode for rescheduling the start, and built-in system control. They are capable of serving for two decades without any failures. But there are isolated situations when failures appear. Experienced specialists even notice characteristic faults. But few people know that it is possible to repair Miele washing machines on your own.

Miele machines are distinguished by a unique drum design, a mode for rescheduling the start, and built-in system control. They are capable of serving for two decades without any failures. But there are isolated situations when failures appear. Experienced specialists even notice characteristic faults. But few people know that it is possible to repair Miele washing machines on your own.

Distinctive features of the unit

The main difference lies in the specifics of the device. High-quality materials were used to manufacture parts; all work was carried out in a factory environment by German craftsmen. It should be added that the equipment uses quite complex electronics. All this introduces certain difficulties into repairing such machines with your own hands.

Carrying out high-quality repair work requires the presence of special equipment that you need to be able to work with. This is one of the reasons that Miele washing machine repairs are trusted to experienced specialists. As follows from repair statistics, the cost of work is quite low. Only two percent of the machines cannot be restored, but it is noted that they have served for ten years or more.

Revolutionary technologies have also occurred in washing clothes, which are performed at a unique speed mode. This system combines a couple of options:

- With the help of the first program, the quality of the process is improved. The result increases by ten percent, detergents are used economically, foam is formed in the optimal volume;

- the second function reduces the process time, the entire cycle takes no more than one hour.

Washing is done economically because the machine independently controls the amount of water required to complete the process.

There is another unique feature of this series. A special option dispenses the amount of powder and rinse aid.

There are several more functions typical for units of this brand:

- program manager - it provides five operations focused on a variety of fabrics and their level of contamination. To select the desired mode, you only need to press the corresponding button;

- mixed load - you can wash different fabrics at the same time. The result is simply excellent, all resources are saved.

- high level of energy efficiency. This means that this is the company that produces high-quality equipment for washing clothes.

Causes of malfunctions of Miele washing machines

The main problem lies in operational violations, voltage drops, leading to short circuits in the electronics of the unit. The hardness of the water also has an effect, depositing impurities on the water heating elements. Scale accumulates on the heating element, which can cause failure of both the element itself and the control module. But such reasons for machine failure occur only through the fault of the user.

Main failures and procedure for their elimination

The most common breakdowns can be listed in the following order:

- a pump for draining water, which can also be called a pump or pipe;

- a sensor device that monitors the liquid level - a pressure switch;

- water heating element (TEN);

- drive belt;

- hatch blocking device;

- sensors and electronic unit.

Let's look at how to deal with such problems on your own.

- Cleaning the drain pump, pipe and filter.

When the machine does not drain water, it is recommended to check the drain filter, the device itself and the pipes. Cleaning the filter in a washing machine of this brand is not fundamentally different from a similar procedure performed in other machines:

- The drain filter is the easiest to clean, so it is recommended to start with this procedure. Here it should be taken into account that in most models this element is located at the bottom right, and in our case it is also located at the bottom, but on the left side;

- you need to open the lid made of plastic material, behind it there is the required plug;

- take a container to collect water or a rag, which is laid out near the filter and placed under the body of the machine;

- Having unscrewed the plug, let the water in the filter drain completely and collect it;

- Using a flashlight, we inspect the hole, remove foreign objects and dirt accumulations from it;

- screw in the plug and check the SMA for its functionality.

Cleaning the drain filter may not achieve the desired results. In such a situation, you need to pay attention to the pump and pipe. It is possible that the blockage appeared in them. In this case, we will check both elements at once:

- First, the pump is removed, for which it is necessary to disassemble the washing machine by unscrewing the front cover, which provides access to the desired point;

- Having prepared a container for collecting water, remove the pipe and drain pump from which the liquid will flow out;

- the connecting clamps on the pipe and the pump, securing them to the tank, are unscrewed, the electrical wiring terminals are disconnected;

- now the clamp connecting the pump and the hose for draining the water is removed;

- after this, the mounting bolts of the pump are unscrewed, which must be removed together with the pipe;

- Each element is checked for blockages, washed, and installed in the reverse order in its place. All that remains is to secure the panel and check how the machine works.

- Replacing the pressure switch.

Such work will not take much time. All that is required is to purchase a similar element without trying to find an alternative replacement for it.

This sensor monitors the liquid level in the tank. If it fails, the error code “empty tank” or “water overflow” lights up on the display. This element cannot be repaired, but can be changed quite simply:

- The top cover is removed from the machine, the pressure switch is located near the side panel;

- the hose is disconnected from the sensor and checked for blockages;

- the failed element is removed, all wiring is disconnected from it;

- the new part is mounted in the reverse order.

- Replacement of heating element and drive belt, electrical check.

If the heating element fails, the washing process proceeds in cold water. It may be longer, which is also considered confirmation of refusal. It happens that during washing the electric machine knocks out. To know for sure that it is the heating element that has burned out, it is removed from the washing machine and checked with a multimeter.

It is important to know here that in Miele machines the water heating element is accessed through the front panel. Having removed it, we find a pair of contacts under the water tank, carefully rocking them and pulling them towards us. Having taken out the heating element, remove the rubber seal.We replace the burnt-out element with a new one, which we install in the vacant connector.

The drive belt may simply fly off, fray or break. All this leads to the drum stopping. Experts note that this problem occurs quite often.

To carry out the replacement you must:

- remove the side panel on the left;

- check the belt for integrity, if necessary, purchase a new one;

- It is first put on the engine, then, pulling upward, it is wound onto the pulley on the right;

- then, holding the already tense part, you should carefully turn the pulley counterclockwise, trying to tighten the belt completely;

- We install the housing cover in place and turn on the unit.

To ensure there is an electrical failure, it is necessary to test and inspect the wiring, connecting terminals and other elements. Moreover, such actions are carried out without fail, even when another malfunction is eliminated and it becomes necessary to disassemble the body of the machine. Checking the electrical circuit is quite simple, but you will have to tinker a little, ringing all the contacts, plug outputs, and connections. All actions can last from forty minutes to an hour and a half, but the work is completely worth it.

You will need a multimeter to check. Its toggle switch is set to the required position, the machine is de-energized, and the test begins. Experts recommend starting all actions with the contacts of the control unit, then gradually moving to the modular device. You will have to unscrew the fasteners of the instrument panel, remove it, and pull out the control unit without disconnecting the wires from it.

Resistance is checked from the start button. If “zero” lights up on the display, then the whole problem is in the contacts.They need to be checked one by one, then the sensors, pressure switch, inlet valve, and water drain pump should be tested. There is a possibility that the problem will not be detected during the first inspection, and all actions will have to be repeated.

There is one important detail - the capacitor of the machine's electric motor is the main problem.

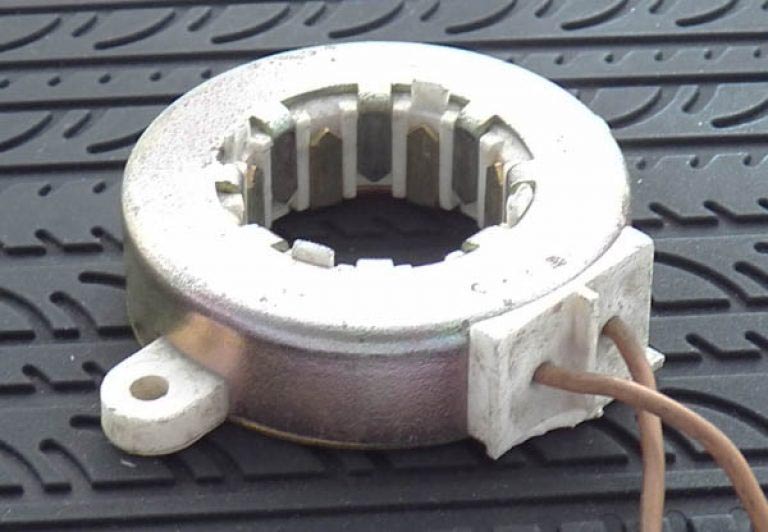

- Checking and repairing the tachogenerator.

This device is very simple and ingenious, it is mounted on the engine, and helps to measure the speed mode of rotation of all moving elements. Without this element, the control unit will not be able to recognize in what mode the drum needs to rotate in order to use the washing program most effectively. It follows from this that the sensor is capable of adjusting this speed.

Getting to the tachogenerator, you will have to gain access to the electric motor of the machine. To do this, you will have to remove the front cover of the unit again. Repairs for such a breakdown are not performed - only a complete replacement of the element. Its cost is low, the necessary wires and a connecting plug are included in the kit. Failure can be detected using a multimeter, which measures resistance. In a normal situation, it should be equal to 70 Ohm, the permissible deviation is 20 Ohm. In other cases, the sensor needs to be replaced.

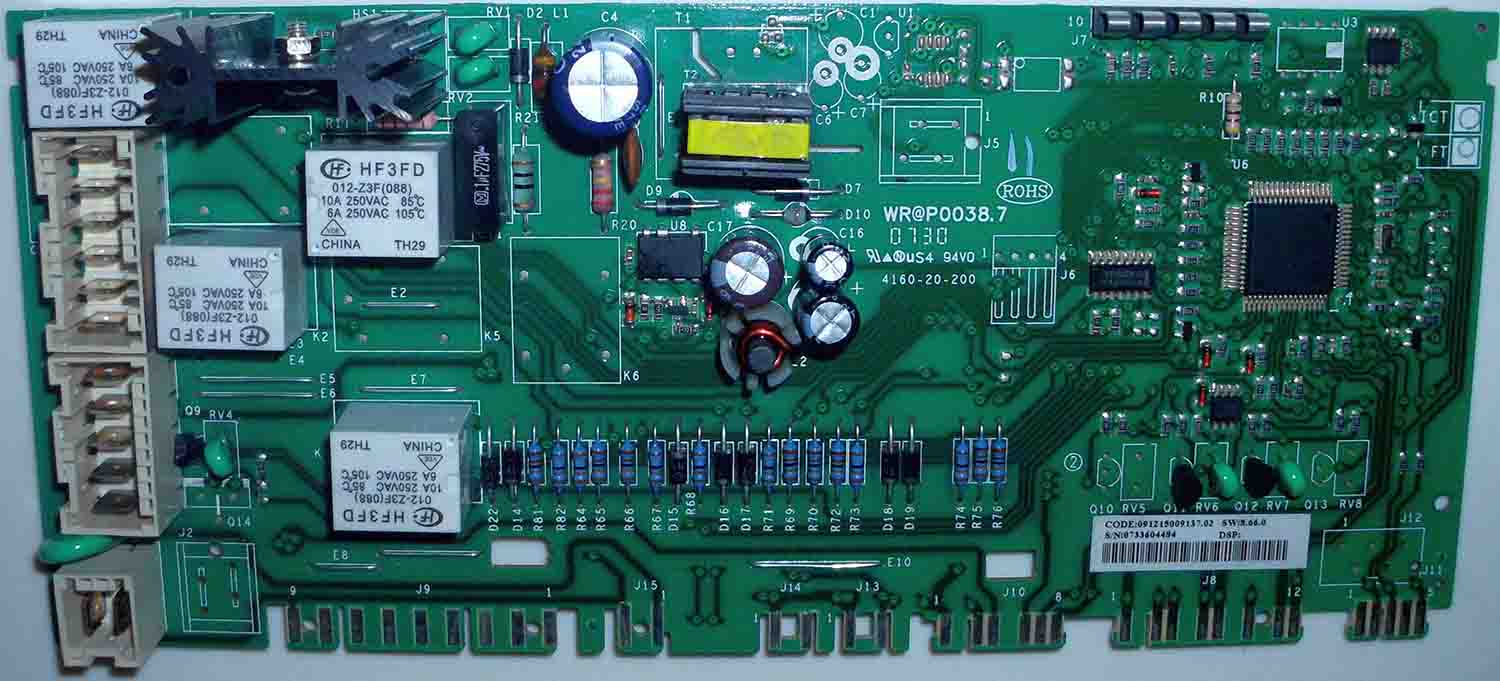

- Checking and repairing electronics.

Probably, this stage of repair is considered the most difficult. In modern models, in addition to the usual control unit board, there are microprocessors that significantly increase the performance of the washing machine and are able to effectively manage numerous programs and sensors. The problem appears as soon as the electronics fail and the question arises of what to do.

At the initial stage, experts advise not to get into the board itself, but only check the machine’s electrical system. There is a possibility that this is where the problem lies. If everything is normal, you need to remove the control unit and send it to the service for testing, or do it yourself. But in the second case, you will need to resolve several issues:

- correctly connect the control unit to the computer using a special COM connector;

- identify and activate software for electrical testing of the machine board;

- Based on the readings received, make sure that the board is faulty. At the same time, you need to know that the values produced by the program are more intended for specialists, and it will be quite difficult for an ordinary user to understand this.

It's probably better to take the board to a workshop. They will tell you for sure whether there is a need to replace it. This element is quite expensive, but a new machine will cost much more.

Conclusion

As a conclusion, we can say that it is best to repair a Miele machine at a service company than to try to fix the problem on your own. You can figure out the water drain pump yourself. It is better to entrust all other cases of failures to be identified and eliminated by experienced professionals.