Regardless of the brand, the average lifespan of any washing machine, subject to all manufacturer’s recommendations, is approximately 10-12 years. However, various factors (hard water, incorrectly selected detergents, power surges, mechanical damage, etc.) significantly reduce the service life of washing equipment.

It is worth noting that if the washing machine does not turn on, this is by no means a prerequisite for replacing it. The malfunction may be so trivial that it may be possible to fix it yourself. The washing machine may not start for several reasons, but if they are detected and eliminated in time, the functionality and performance characteristics will not be affected in any way.

Reasons why washing equipment does not turn on

Before you get rid of a washing machine that has stopped turning on, you need to check some of its components yourself.It is quite possible that you can fix most of the problems yourself without contacting a service center.

Depending on the breakdown, the unit may either not turn on or simply not run a certain washing program. Only competent and timely elimination of these faults will help to significantly increase the service life of the washing machine and save a significant amount of money needed to purchase new equipment.

We will describe the main reasons why the washing machine stops turning on:

- lack of electricity in the network;

- the power cord is faulty;

- failure of the wash start button;

- incorrect operation of electronics;

- problems with various filters;

- failure of the electric motor;

- violation of the integrity of internal electrical wiring.

Let's look at each of the reasons in more detail, and also find out options for eliminating them.

The socket is faulty or there is no electricity in the network

The first step is to check the serviceability of the power outlet, since it may lack contact or have mechanical damage, due to which normal power supply to the electrical appliance is impossible. The easiest way to check the functionality of the outlet and the presence of electricity in the network is to connect another consumer to it, for example, a hair dryer. It is necessary to disassemble the socket for diagnostics carefully, observing all electrical safety rules.

We strongly recommend that if serious faults are identified that cannot be corrected on your own, you contact a qualified electrician.

Checking the water supply

The washing machine may stop starting because there is no water flowing into the drum. In this case, you should check its presence and the pressure in the tap.

If the water pressure is normal, but the washing process still does not start, you need to check the water supply tap directly to the washing machine. It should be in the open position.

If the operation is not normal, proceed to checking the input filter. Its unsatisfactory condition can be one of the reasons why the machine does not start. The element is located at the end of the water supply hose.

If there is an AquaStop system, you must make sure that it is not activated.

The power cord or plug of the washing machine is damaged

The power cord is constantly subject to deformation during operation, due to which it can be damaged at any time, due to which the power supply will completely stop, and the washing machine will not start. To determine the presence of damage, it is necessary to visually inspect the cord and the power plug. Pay attention to traces of burning insulation and visible defective areas.

It is worth noting that if a break in the integrity of the power cord or plug is detected, their further use is strictly prohibited, since this may cause a short circuit or electric shock.

You can check the serviceability of the power cord using a multimeter. It is enough to "ring" each of the wire cores. If a break is detected, we recommend replacing the power cord completely, and not restoring its integrity by twisting and then insulating it. If the washing machine is connected to the network using an extension cord, then we recommend, in the event of a lack of voltage, first of all checking it. To do this, plug any consumer of electrical energy into the extension cord, for example, an electric kettle or a hair dryer.

Malfunction of the wash start button

If none of the indicators on the front panel are lit and the device does not respond to startup, it is quite possible that the reason for this lies in a malfunction of the “Power on” (“Start”) button. It is worth emphasizing that this is one of the most common reasons for the washing machine not to start, which is typical for models with push-button control.

To verify that the button is faulty, you need to diagnose it. This is done as follows:

- The washing machine is cut off.

- The top panel is dismantled. To do this, unscrew the upper fixing bolts in the rear, and then move the cover slightly to the side.

- The control panel must be removed. To do this, remove the powder tray, then unscrew all the fasteners and bend the latches. This must be done as carefully as possible so as not to break them.

- You should remember (draw or photograph) the location of the contact wires on the switch, and then disconnect them.

- To check the functionality of the button, after disconnecting it, the contacts should be connected directly and the power cord plug should be plugged into the network. If the machine turns on, it means the switch is faulty and needs to be repaired or replaced.

Important: in order to avoid an accident when checking the functionality of the power button, it is necessary that the directly connected contacts do not come into contact with metal parts of the washing machine.

If a button malfunctions, do not immediately throw it away and purchase a new one. It is quite possible that the reason is that it is stuck due to the accumulation of dirt, and simple cleaning will be required to restore functionality. To do this, you must first clean the switch seat.To do this efficiently, you should remove the front panel, first disconnecting the board. The plastic surface can be wiped with a soft cloth and cleaning agents. Next, you should carefully clean the board.

Noise filter failure

Each washing machine contains a small device whose purpose is to dampen electromagnetic radiation during the washing process. It's called a noise filter. Thanks to its presence in the design of the electronic system of the washing machine, nearby electronics are completely protected from the harmful effects of electromagnetic waves. In addition, the filter protects the electronics of the washing machine from voltage surges, due to which it may stop working. If the noise filter completely fails or begins to function incorrectly, the washing machine will stop turning on.

Reasons for interference filter failure:

- long-term use of the washing machine;

- mechanical damage to the part;

- voltage drop;

- manufacturing defects;

- short circuit.

If the filter is faulty, the integrity of the entire electrical circuit is disrupted; accordingly, the washing machine cannot function, since its main energy consumers remain de-energized.

We emphasize that the higher the cost of washing equipment, the greater the number of programs and useful functions it has; accordingly, in the event of a voltage drop or short circuit, important and expensive elements can fail: electric motor, computer, heating element, etc. In view of this, the importance of having a surge protector is not worth talking about. This element must always be maintained in working order.

Broken hatch locking device

If the power indicator on the front panel lights up, but after selecting and starting the washing mode, “ERROR” appears on the information display, it is quite possible that the malfunction lies in the door locking device. Structurally, the blocker is a small electromechanical device, the operating principle of which is based on the functioning of a bimetallic plate. Due to long-term operation and constant temperature changes, the hatch locking device may begin to function incorrectly or even fail completely.

The main sign that the locking device needs repair is the absence of a characteristic click when the hatch is closed. In order to fully verify this, you must disconnect the device. True, you will need to partially disassemble the washing machine.

Let us describe the correct sequence of actions:

- There is a special fixing clamp on the hatch cuff, which must be carefully removed.

- Next, on the side of the hatch blocking device, bend the cuff.

- Now you need to dismantle the lock mechanism itself. To do this, you need to unscrew the fixing bolts and remove the power wires.

To check the functionality of the hatch locking device, you will need a multimeter, with which the value on the lock contacts is measured. If the blocker fails, it must be replaced with a new one. Note that the device is inexpensive, so there is absolutely no need to restore its functionality.

If the drum hatch locking device is functioning properly, but the washing machine does not turn on, you need to check the control unit, electric motor, wiring, and other components.

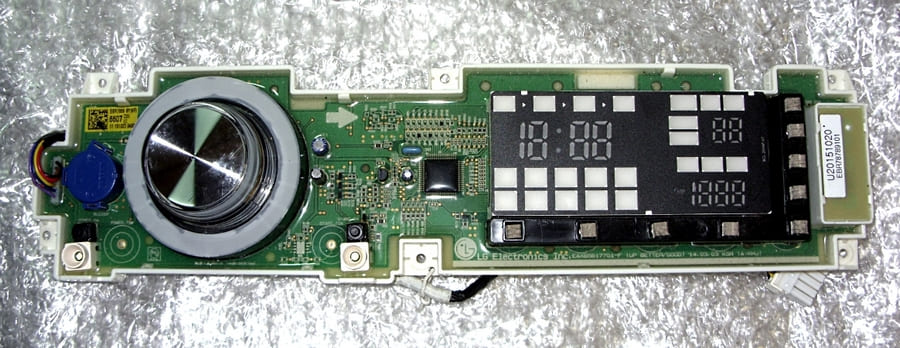

The control unit or programmer is faulty

Diagnostics of these electronic modules of the washing machine should be carried out only after the measures described above. In addition, it is necessary to check the condition of the internal electrical wiring and the correct connection of all circuit elements.

We emphasize that the electronic control unit and programmer should only be checked by a highly qualified specialist. In addition, these components are the most expensive in the design of a washing machine, and sometimes replacing them can be almost comparable to the price of new equipment. Therefore, it may well turn out that if the ECU or programmer on expensive models fails, it will be faster and easier to purchase a new washing machine than to repair the old one.

Common causes of failure of the control unit and programmer:

- manufacturing defects;

- moisture ingress;

- voltage drop;

- long operational period;

- careless handling of the washing machine.

Only a highly qualified specialist can competently test both units. We do not recommend diagnosing the performance of these modules yourself.

The indicators are on, but the wash does not start

We list the main reasons for this problem:

- Drum overload. If you load more laundry than the specified amount, the washing machine may not start. Most models have a drum loading sensor, which, in case of overload, blocks the motor from starting. Excess weight of laundry in the drum can be indicated by a corresponding LED on the front panel or an audible signal.

- Problems with the drive belt, which can result from both long-term use of washing equipment and its downtime. The belt can stretch, break, or fly off.In this case, after starting the washing process, the electric motor starts running idle, without rotating the drum. Belt replacement recommended.

- A small foreign object has entered the area between the body and the drum, which interferes with the normal operation of the washing machine. In this case, the drum becomes blocked, as evidenced by the corresponding indicator.

- Failure of the heating element or pressure switch. Typically, such malfunctions occur after voltage surges in the electrical network. The functioning of the washing machine can be normalized only after replacing these elements.

- Wear of bearing pairs. This malfunction is a consequence of prolonged and intensive use of washing equipment. The problem is solved only after complete replacement of worn out parts.

- Availability of transportation bolts.

- Electric motor problems. These faults are classified as difficult to fix, so only a highly qualified specialist should be able to find and fix them. The reasons for electric motor failure are: voltage drop, moisture ingress, short circuit, natural wear and tear of motor elements, manufacturing defects, mechanical damage to parts.

- Failure of the electronic control unit, as a result of which the operation of the washing equipment is completely paralyzed. The main reasons for ECU failure include voltage drop, moisture, short circuit and prolonged operation. Depending on the breakdown, the control unit must be re-flashed or completely replaced.

In case of incorrect operation of the electronics in washing machines, we strongly recommend that you contact a service center to diagnose and eliminate the existing problems.

Indicators blink randomly

It is quite possible that the reason for this behavior of the washing machine is the failure of the control board. Most often this is a consequence of a short circuit, moisture or voltage drop. To protect the control board, it is coated with a special compound that completely prevents the penetration of moisture. However, during repair work, the protective layer may be damaged.

Water got on the electronics

It happens that the hoses and pipes inside the washing machine are damaged, which causes water leaks that can get on the electronics and damage them. These are quite serious faults that can cause a short circuit. If water gets on an electrical component of the engine, it is possible that it will fail and will need to be replaced.

If a puddle of water is found on the floor next to the washing machine, you must immediately turn off the power to the equipment and determine the cause of the leak. We recommend calling a specialist who will diagnose and eliminate the identified faults.

Remember: further operation of a washing machine that has been found to have a water leak is unsafe!

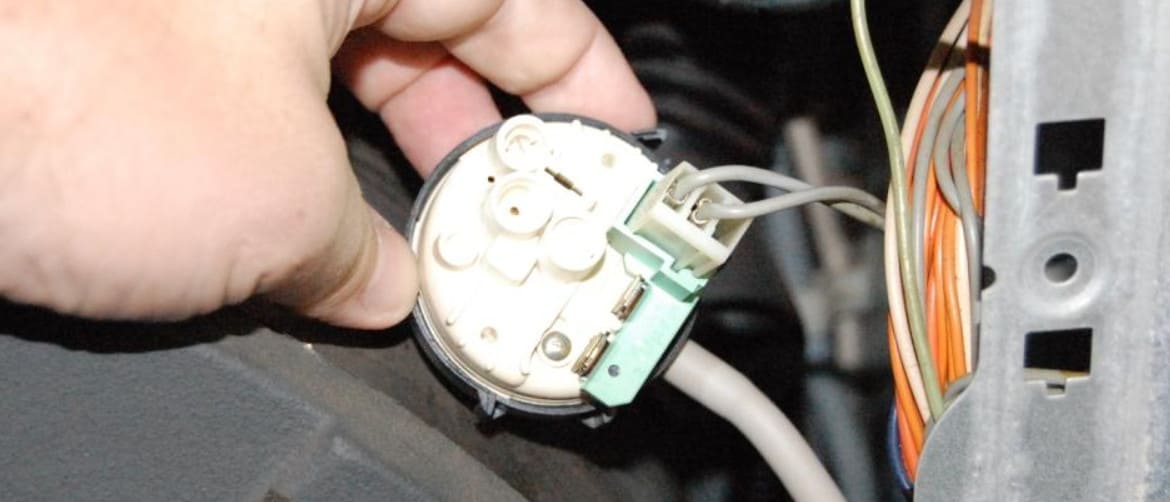

Damage to the pressure switch (water level sensor)

The water level sensor is one of the main elements in the system, which ensures the safe operation of the washing machine. Let us describe some signs of a faulty pressure switch:

- If your washing machine has a self-diagnosis function, an error code will appear on its information display. A decoding of all codes is available in the operating instructions for the equipment. Based on the information received, the user draws conclusions about the serviceability of certain elements of the washing machine, including the water level sensor.

- The absence of water in the drum after starting the wash is evidence of a malfunction of the pressure switch.

- Insufficient or too much water in the drum.

- Wet laundry after the spinning process is completed is also evidence of a faulty water level sensor.

The pressure switch is a necessary element of the washing machine, the serviceability of which determines the safe operation of the equipment, therefore, if the problems described above are detected, they must be eliminated immediately by replacing the failed sensor.

The belt came off

If, after starting the washing program, you hear the sound of an electric motor running, but the drum does not rotate, it is quite possible that the drive belt has fallen off or broken. This element wears out during operation of the washing machine and over time requires complete replacement, since it can no longer perform its functions. You can replace it yourself. There are many detailed instructions on the Internet describing all stages of work.

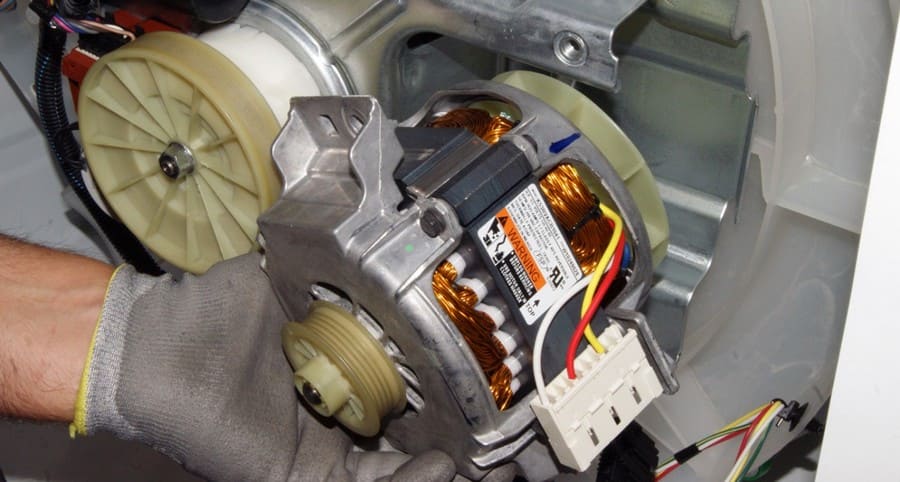

Electric motor failure

The main driving unit of the washing machine is an electric motor, which ensures the rotation of the drum during operation. If the motor fails, the selected wash process will not start.

The following types of electric motors are used in modern washing machines:

- asynchronous - installed extremely rarely. It features stable operation and a long service life;

- collector - used on models of the middle and budget segment. Less reliable;

- A direct drive motor has a complex design, so restoration of its functionality must be carried out exclusively by a highly qualified specialist.

The electric motor is one of the main units of the washing machine, the serviceability of which determines the safety and duration of its operation.

How to prevent washing equipment breakdowns?

To extend the life of your washing machine, just follow these simple recommendations:

- Read the operating instructions.

- To prevent voltage surges and protect the washing machine, voltage stabilizers should be used.

- Do not overload the washing machine.

- Keep your equipment clean, be sure to wipe the drum loading hatch dry after each wash. Watch the rubber seals.

- For washing, use only appropriate powders, which contain special compounds that prevent the formation of scale on the heating element and various deposits on the walls of the drum and the drain hose.

- Every six months, run a preventive wash without laundry using a special anti-scale agent.

Compliance with all recommendations will significantly increase safety and increase the service life of washing equipment.

Conclusion

A modern washing machine is a complex technical device that requires careful handling. For example, if the electronic control unit is damaged, it will need to be completely replaced, and this is a rather expensive undertaking. Restoring the functionality of such equipment should only be carried out by specialists who have the necessary tools at their disposal. Following all the recommendations described in the instruction manual will help to significantly extend the life of the washing machine.