Even the most expensive and high-quality automatic washing machine cannot boast of absolute noiselessness. During work, sounds will definitely be heard: a slight whistle, hum, creaking. A washing machine hums when washing - this is normal, but only if the nature of the sounds produced does not cause concern and the volume does not exceed acceptable values. An excessively loud roar of a rotating drum, accompanied by a crash and rumble, should certainly make the owner wary; these are most likely symptoms of a serious malfunction.

Even the most expensive and high-quality automatic washing machine cannot boast of absolute noiselessness. During work, sounds will definitely be heard: a slight whistle, hum, creaking. A washing machine hums when washing - this is normal, but only if the nature of the sounds produced does not cause concern and the volume does not exceed acceptable values. An excessively loud roar of a rotating drum, accompanied by a crash and rumble, should certainly make the owner wary; these are most likely symptoms of a serious malfunction.

Noise standards

There is no such term as “buzzing loudly”; it is purely a subjective perception. The level of noise emitted by the machine is determined using special equipment. The maximum values should not exceed the values specified in the documentation; their values directly depend on the type of drive of the washing machine.

Direct drive washing machines can produce noise levels of 52-70 dB. For devices using belt transmission, the permissible values are slightly higher - 60-72 dB.

At home, it is unlikely that it will be possible to accurately measure noise levels, however, the threshold of the permissible value can be heard by ear. If the operation of the washing machine is perceived as background noise without causing discomfort, everything is fine. If the hum and crackling noises come to the fore during washing, drowning out other sounds, you should think about it. It is possible that the machine is faulty.

Causes of noise

Excessive noise during operation of a washing machine can be caused by a number of reasons. In rare cases, this is a careless attitude towards technology, most often it is a sign of imminent failure of the device. Among the main reasons for high noise levels:

- incorrect installation of the machine;

- defective cuff of the loading hatch;

- foreign objects that have fallen inside the washing machine;

- wear of moving parts of the device;

- loose counterweights.

If you can correct mistakes made during installation yourself, then to solve other problems that create noise you will have to partially or completely disassemble the machine. It is up to the owner to do it himself or go to a workshop. In any case, before sounding the alarm, you should make sure that the machine is stable and that there is no excessive vibration during operation.

Noise due to improper installation

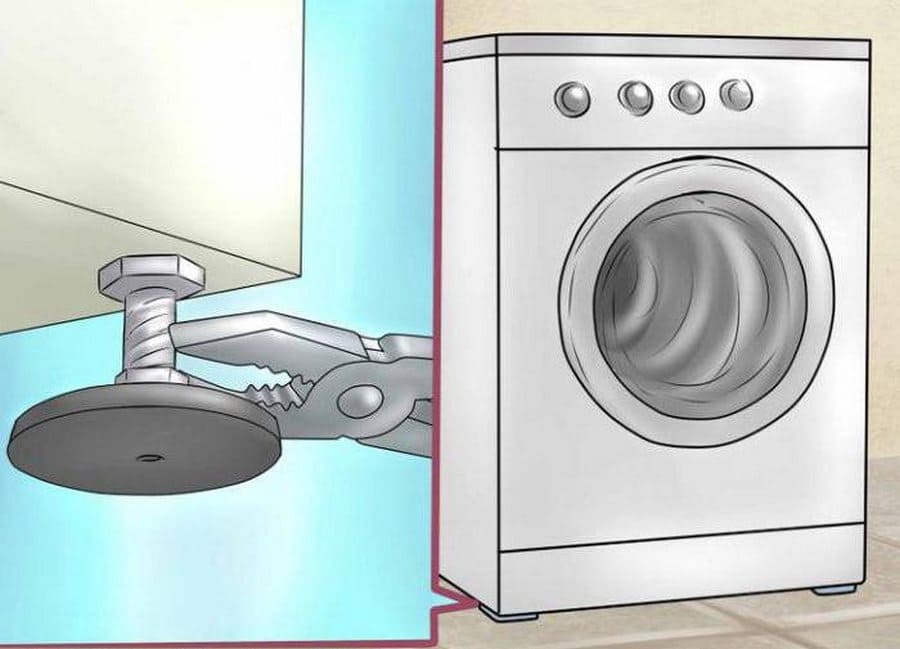

If the washing machine makes noise on the first day after purchase, it is logical to assume that it was installed incorrectly. It is likely that to correct the situation it is enough to simply level it by twisting the legs.

In order for the machine to work for a long time, not vibrate and not make unnecessary noise, during installation you need to pay attention to a number of significant points.

- Make sure that the transport bolts are unscrewed.Quite often, beginners who install the machine themselves simply forget about them.

- The floor on which the washing machine is installed must be level and durable. Do not operate the washing machine on a shaky, creaky floor.

- It is important to adjust the legs correctly. If necessary, you can use special anti-vibration inserts.

Even if the washing machine has been operating for some time, before you start looking for the cause of excessive noise inside it, it would be a good idea to make sure that the installation is stable and correct.

Hatch cuff defect

Some may find it strange that the cuff of a washing machine can become a source of suspicious noises, but nevertheless it is true. The purpose of the cuff is to prevent water from pouring into the gap between the body and the hatch during operation. If the cuff is installed correctly and the material from which it is made has not lost its elasticity, a small gap remains between it and the rotating parts. The cuff is not in contact with the drum. If it is distorted, the situation changes. The edges of the cuff go inward, preventing the normal rotation of the drum, thereby causing noise.

It is worth noting that such a malfunction, which creates an unpleasant noise, is more often found in inexpensive devices from little-known manufacturers; washing machines from LG, Samsung, Indezit and other world brands are free of this drawback.

If abrasions are visible on the cuff, this is the reason. You can correct the situation in the following way:

- open the hatch, turn the drum by hand;

- determine the part that clings to the cuff;

- stick a piece of fine sandpaper on the drum;

- run the washing machine in spin mode.

As the drum rotates, the sandpaper will remove excess rubber and friction should stop. Of course, this method will only work if the size of the protruding edge of the cuff does not exceed a few millimeters. Otherwise, the cuff will have to be replaced.

If the cuff is in order and the noise does not stop, you need to move on to checking other parts of the washing machine. Further actions involve disassembling the machine, completely or partially. Before getting down to business, you need to soberly assess your capabilities, and in case of the slightest doubt, contact specialists.

Loose Counterweight

The counterweight is a very simple device in the washing machine that can cause noise. Actually, this is a piece of concrete installed inside the washing machine. Its task is to dampen the inertia that arises during the rotation of the drum. Despite its apparent simplicity, it can become loose and, instead of calming the vibration of the washing mashine, bother its owner with creaks and noise.

The counterweight is easy to access - you just need to remove the top cover. Often, during operation, the mounting holes break, and the concrete block begins to “walk”, making a loud noise. If the counterweight moves freely, but the bolts cannot hold it because the holes are larger than the bolt heads, the counterweight will have to be replaced.

Worn pulley or drive belt

If a belt-driven device is being considered, another reason why the washing machine is noisy during operation may be wear and tear on the rotation transmission system, namely: a loose pulley or worn out belt. To eliminate the noise in this case, you will have to partially disassemble the machine.

- The back cover is removed, it is held on by several bolts or screws.

- The big wheel in the middle of the washing machine is the pulley. It should be carefully examined, checked by hand for play. If the pulley "walks" there is nothing left to do but replace it.

- The belt is thrown over the pulley. It must be removed and examined most carefully. In case of severe wear, signs of delamination, cracks, the belt is changed.

You should also pay attention to the condition of the drum shaft. If the pulley has been poorly secured for a long time, wear may form on the shaft.

Noise due to wear of the drum bearings

Another common cause of extraneous noise is the failure of the drum bearings. It is easy to check their condition, you do not even have to disassemble the washing machine. You just need to turn the drum a few times by hand. If it moves freely and no extraneous noise is heard during rotation, the bearings are normal. If a characteristic crunch is heard, the drum resists rotation - the bearings must be replaced.

Basically, the bearings of the washing machine fail and create noise due to the drying out of the seal, which ensures the tightness of the drum. Water gets inside the bearing, it rusts and wears out quickly and begins to create noise. Therefore, if the problem is caused by the bearing, you must immediately change the seal, otherwise you will soon have to disassemble the device again. The degree of complexity of the bearing replacement procedure depends on the model and manufacturer of the washing machine. The procedure is different for machines manufactured by Samsung, Ariston, LG and others. Before getting down to work, it would be a good idea to study the instructions for disassembling a specific model, watch a video on the topic.The big wheel just in the middle of the washing machine is the pulley. It must be carefully inspected, checked by hand for the presence of play. If the pulley “goes” there is nothing left to do but replace it.

The belt is thrown over the pulley. It must be removed and inspected most carefully. In case of severe wear, signs of delamination, cracks, the belt is replaced.

It is also worth paying attention to the condition of the drum shaft. If the pulley has been poorly secured for a long time, wear may form on the shaft.

- Noise due to worn drum bearings

- Another common cause of extraneous noise is failure of the drum bearings. It’s easy to check their condition; you don’t even have to disassemble the washing machine. You just need to turn the drum several times by hand. If it moves freely and no extraneous noise is heard during rotation, the bearings are normal. If a characteristic crunch is heard, the drum resists rotation - the bearings must be replaced.

- Basically, washing machine bearings fail and create noise due to the drying out of the oil seal, which ensures the tightness of the drum. Water gets inside the bearing, it rusts and wears out quickly and begins to create noise. Therefore, if the problem is caused by the bearing, you must immediately change the oil seal, otherwise you will soon have to disassemble the device again.

- The degree of complexity of the bearing replacement procedure depends on the model and manufacturer of the washing machine. The procedure is different for machines manufactured by Samsung, Ariston, LG and others. Before getting down to work, it would be a good idea to study the instructions for disassembling a specific model and watch a video on the topic.

- In general, work to eliminate noise is carried out in the following sequence:

- The top cover of the washing machine is removed.

- The dispenser is removed and the control panel is removed.

The front panel is removed; as a rule, the bolts securing it are hidden under the cuff.

The screws holding the back cover are unscrewed.

The heating element is disconnected and removed.

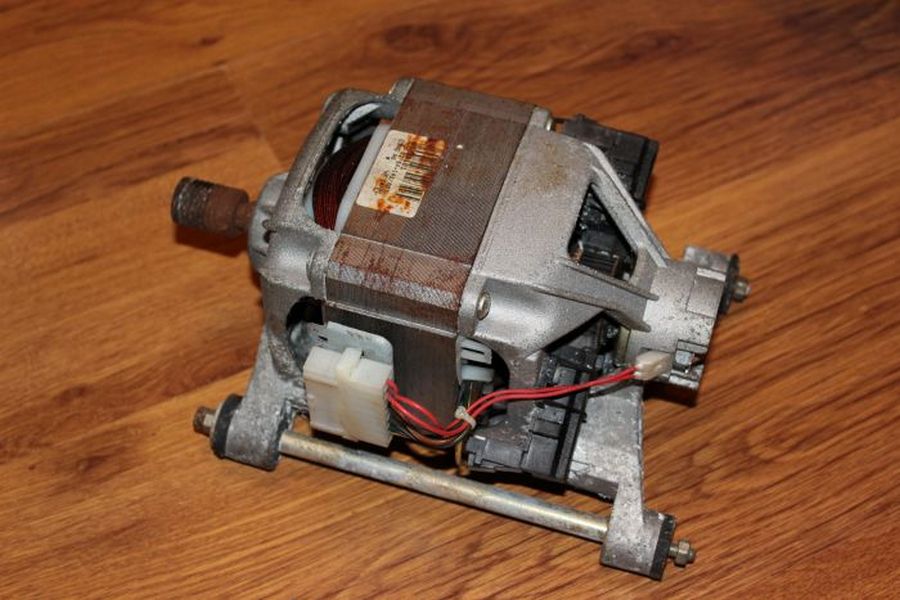

The engine is removed.

The tank is removed.

Next you need to disassemble the tank. In most cases, it consists of two halves bolted together. Worn bearings are removed and others are pressed in. New bearings must be of the closed type, otherwise they will not come out for a long time. After this, the device is assembled in the reverse order.

Noise due to problems with the electric motor

The next unit that can cause noise in a washing machine is the electric motor. The most common problem is worn brushes. In this case, the noise is especially loud, in addition to the hum, a characteristic smell is felt, the drum moves jerkily.

The procedure for replacing the brushes itself is not particularly difficult, but one must take into account the fact that you can only get to the motor by completely disassembling the device.

Loud noise when draining water

A special case is that the washing machine works fine, but as soon as the water needs to be drained, it makes a lot of noise. The cause may be a dirty drain filter or a faulty pump. Before handling the pump, you should remove and clean the filter. If it is in order, you need to remove and check the pump.