Beko washing machines are high-quality and reliable equipment with wide functionality. From time to time it breaks down, in which case the self-diagnosis system notifies the user about the type of breakdown by flashing indicators or displaying a special message consisting of numbers and letters on the screen. To determine the malfunction, you need to know how to decipher the error codes of a Beko washing machine.

Beko washing machines are high-quality and reliable equipment with wide functionality. From time to time it breaks down, in which case the self-diagnosis system notifies the user about the type of breakdown by flashing indicators or displaying a special message consisting of numbers and letters on the screen. To determine the malfunction, you need to know how to decipher the error codes of a Beko washing machine.

Deciphering error codes on Beko washing machines

If the error appears for the first time, it may not indicate a malfunction, but a failure due to a voltage drop. You need to unplug the Beko washing machine from the socket, leave the appliance for fifteen to twenty minutes, and then plug it back in and try to start it. If the error appears again, you need to start deciphering the code.

H1

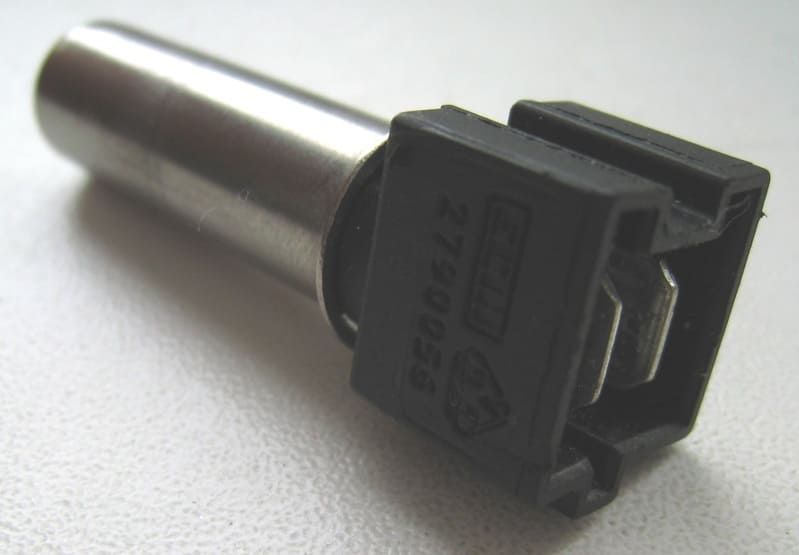

In inexpensive models, this error code corresponds to the first LED that lights up (from left to right). It notifies you that the temperature sensor is faulty, so the water in the washing machine does not heat up or, conversely, reaches higher temperatures than set by the program.It is necessary to inspect the sensor, check the condition of its contacts, and test it with a multimeter. If it is faulty, it will need to be replaced.

H2

On simple models of Beko washing machines, the second indicator on the left lights up. Notifies that The heating element is damaged. Linen is washed in cold water and remains dirty. It is necessary to disassemble the device to gain access to the heating element, turn off the power, ring with a multimeter and ensure that the display reads between 20 and 30 ohms. This means that the part is working properly, and the user should check the condition of the wiring going from the heating element to the control unit. Any damaged chain links will need to be repaired.

H3

The first and second LEDs on the left are lit. The heating element works without turning off, as a result the liquid overheats. It is necessary to ring the temperature sensor responsible for the water heating temperature. Next, you will need to diagnose the system board and check the triac that controls the thermistor.

H4

This error code corresponds to the third LED on the left being constantly lit on Beko machines without a display. The triac that controls the liquid fill valve is damaged. You should inspect the wiring going to the module and check the contacts. If traces of burning are found, the damaged link must be replaced. If defects are found on the control module, it should be replaced with a working one or contact a service center for repair.

H5

On simple models, this code is determined by the glow of the first and third indicators. This message indicates that the drain pump is damaged or there is a blockage in the system. You should sequentially clean the liquid drain filter and the pipe, then inspect the hose make sure that there are no blockages in it, and that it is not bent or pinched by foreign objects. The last thing you need to do is remove the pump, inspect it, remove blockages if there are any, check the impeller, remove any wound wool, threads and hair. If all these steps do not bring results, you need to install a new drain pump.

H6

Error code H6 or continuous lighting of the second and third LEDs indicate problems with motor control. It is necessary to diagnose the triac on the system board that controls the operation of the engine. If this unit is working properly, you need to inspect the wiring for breaks and contacts, make sure that there is no damage or traces of burning. Next you will need carry out diagnostics of the motor itself. Faulty elements will need to be replaced with working ones.

H7

The constant lighting of the first, second and third indicators and error code H7 indicate that the operation of the pressure switch (liquid level sensor) is impaired. You need to check how tightly the door closes and if there are problems, replace the hatch locking device. Next, you need to make sure that there is water in the tap and the pressure is sufficient for the Beko machine to operate. You should also check the valve at the inlet of the device and make sure it is open. After this you will need to carry out diagnostics of pressure switch and wires from the sensor to the system board. The inlet valve needs to be ringed. All faulty components should be replaced with new ones.

H11

This error and the continuous lighting of the third and fourth LEDs indicate a lack of communication with the engine. To troubleshoot the problem, you need to check the wiring from the motor to the system board, the control unit, the tachometer and the engine itself.

Preventive measures

In order for the Beko washing machine to break down as rarely as possible, it is necessary to regularly carry out preventive maintenance.

- On average, once every 6 months, and then depending on how often the washing machine is used, it is necessary to clean the drain filter from accumulated dirt, and also wash the mesh at the inlet.

- The washing machine must be connected to the network through a voltage stabilizer. It can save the electronics from an unexpected voltage drop.

- A cleaning filter must be installed at the inlet of the washing machine. This will reduce scale deposits and extend the service life of the heating element.

- Electronics are one of the weakest points of Beko machines and other brands, so it is better to install the equipment in a dry room to avoid corrosion and liquid getting on the system board.

Conclusion

If the Beko washing machine fails, it reports the malfunction by lighting up certain LEDs or a special code on the display. To determine what exactly happened to the equipment, the user needs to decipher this message. This will help you understand whether you can fix the problem yourself or whether it is better to contact professionals.