After some time from the moment operating the washing machine any of its elements may lose their functionality. For example, a violation of the water intake, expressed in underfilling or overfilling of liquid, will tell you that there are problems with the sensor that controls its intake. It is not always necessary to replace it; sometimes it is enough to adjust the pressure switch of the washing machine so that it works normally. By performing these steps yourself, you will not spend extra money on a new element and will extend the life of the existing sensor.

After some time from the moment operating the washing machine any of its elements may lose their functionality. For example, a violation of the water intake, expressed in underfilling or overfilling of liquid, will tell you that there are problems with the sensor that controls its intake. It is not always necessary to replace it; sometimes it is enough to adjust the pressure switch of the washing machine so that it works normally. By performing these steps yourself, you will not spend extra money on a new element and will extend the life of the existing sensor.

Options for pressure switches, principle of operation, consequences of failure to operate

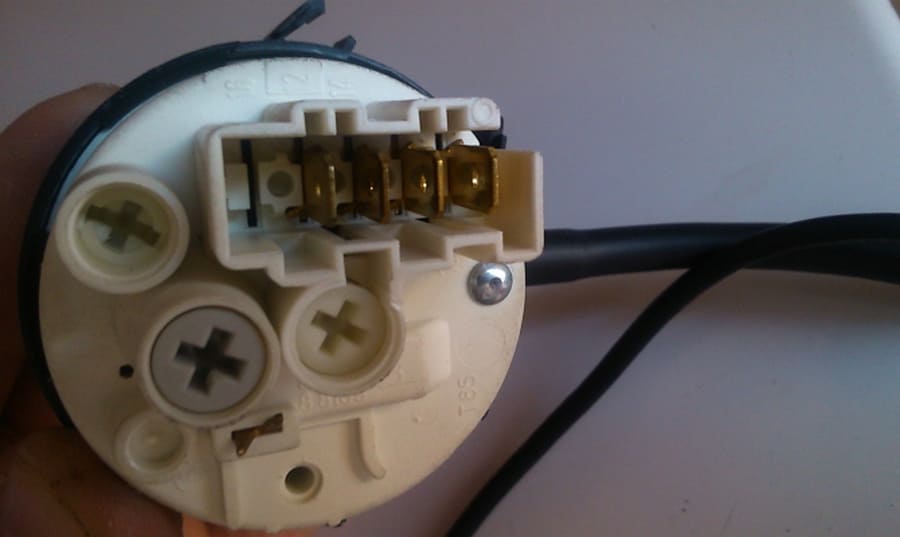

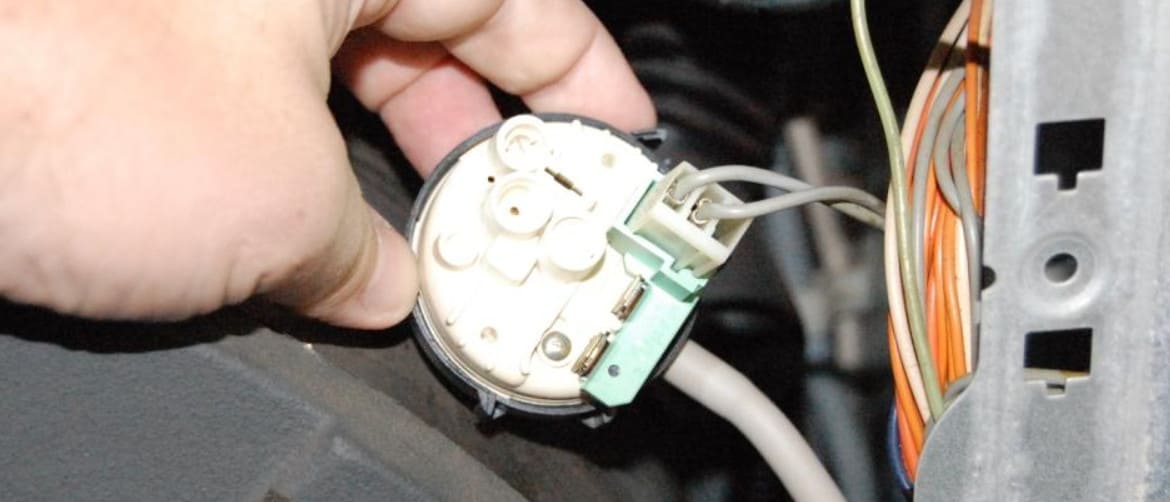

To find out where it is located this sensor is in the washing machine, you will have to remove the top cover of the unit. The pressure switch looks like a flat corrugated washer, to which wires are connected on both sides, and at the end there is a plastic tube. There are washing machines with an oval sensor that has only two contacts - a wire and a tube.

The sensor is essentially a pneumatic relay, which is triggered by air pressure created in a tube connected to the tank of the washing unit.The water flowing into the drum creates a certain pressure, the air begins to press harder on the relay membrane, which closes or opens the contacts, allowing current to pass through the wiring and transmit the necessary command to the control unit.

If there is no signal to start the operation, or there is a lack of continuity in the circuit, the control unit stops the program, sending an alarm signal to the display panel. Eg:

- LG gives a PE signal;

- SMA Ariston and Indesit signaled with codes F04 and F05, respectively;

- SMA from the company Bosch will notify you of the problem with code F26;

- Electrolux for this case it has several versions – E11 – E 12; E21 – E22;

- Kandy – F03.

If the water control sensor begins to work incorrectly, certain malfunctions may appear in the future:

- there will be a transfusion of water in the tank, the device will constantly draw and drain liquid;

- there will be insufficient water for washing, which will deteriorate the quality of the washing machine;

- the water after washing will not drain completely; after spinning, the laundry will remain damp;

- the program will start without water, after which the water heating element will overheat and fail.

Preliminary actions

As soon as you discover a malfunction, you should understand whether the reason actually lies in the part that controls the water level. It is necessary to carefully inspect the water intake system, check the sleeve and fitting of the water intake sensor, and the transition chamber section. When inspecting these parts, you should not find any tears or abrasions, as well as plaque from washing powder.

If detergent is detected on the parts, all components must be washed, after which a second attempt is made to start the washing machine. It is quite possible that you have restored the ability of the pressure switch to work.

Secondly, the correctness and strength of the electrical wiring connection to the part is checked. There is a possibility that one of the wires is worn out or bent. Having discovered such a defect, we eliminate it and perform a test run again.

Diagnostics is performed using a tube whose diameter matches the size of the part’s hose. We put one end of the tube on the instrument fitting, and blow into the second. If the part that controls the water intake is in good condition, light clicking sounds will be heard.

When this method of checking does not help identify problems, the pressure switch will have to be disassembled.

Adjusting the pressure switch

To adjust the part that controls the water level in the washing machine, there is no need to call repair specialists, because such work can be done independently. You must follow the sequence of actions exactly and work carefully. So, the algorithm for adjusting the pressure switch of a washing machine is as follows:

- the laundry washing unit is disconnected from the electrical network and water pipe;

- Having unscrewed the bolts and disconnected the wiring, remove the pressure switch;

- we find special screws that are used to tighten or loosen the contacts inside the device;

- remove the sealant from their surface.

All of the above actions can be attributed to the preparatory stage, because the main work on adjusting the sensor is still ahead. You will have to try to catch the moment of approaching and opening the contact group using the stripped screws. In this case, the well-known “poke method” is used, because only a professional washing machine repair specialist can have a special device for performing such work. You will have to act as follows:

- the first screw is turned half a turn, the pressure switch is connected to the machine, the washing machine starts in operating mode;

- If initially the washing mashine took in little water, and after adjusting the fluid it became more, you are on the right track. All that remains is to unscrew the screw further in the chosen direction and fill it with sealant;

- if manipulations with the bolt produce the opposite result, it will have to be unscrewed in the opposite direction, making one or one and a half turns.

The adjustment did not give a positive result: what to do?

It is quite simple to independently determine that the pressure switch has failed - signs of its failure clearly confirm the problem. But adjusting the part does not always help - there are situations when a complete replacement of the part is required.

It will not take much time to install a new water control sensor. It is necessary to partially disassemble the equipment to gain access to the pressure switch. After this, remember electrical wiring diagram, disconnect it from the contacts and remove the pressure switch.Further actions are performed in the following sequence:

- a new pressure switch is attached to the system, similar to the failed one;

- a hose is connected to the water control sensor tube and secured with a clamp;

- all connections must be checked for kinks, cracks and other damage;

- The wiring is connected according to a known scheme;

- assembly is performed in reverse order, the device is started to test for functionality.

Conclusion

Remember that in a laundry washing machine, every detail has its importance. And if all elements of the unit are in good condition, then the laundry will be washed at the proper level. We recommend that you promptly pay attention to the slightest deviations from the standard operating cycle, if you have the opportunity to repair the washing equipment yourself, or invite a specialist to help.