In modern washing machines from Samsung, Bosch, Indesit and other manufacturers, the pump is designed to pump water into the tank and drain dirty liquid into the sewer. Sometimes this important component breaks down, in which case the equipment reports a malfunction by displaying a special code on the screen. To fix the breakdown, the user can turn to professionals, but if there is a desire to save a significant amount, the repair can be done on your own if you know how to disassemble the pump of a washing machine.

In modern washing machines from Samsung, Bosch, Indesit and other manufacturers, the pump is designed to pump water into the tank and drain dirty liquid into the sewer. Sometimes this important component breaks down, in which case the equipment reports a malfunction by displaying a special code on the screen. To fix the breakdown, the user can turn to professionals, but if there is a desire to save a significant amount, the repair can be done on your own if you know how to disassemble the pump of a washing machine.

Signs and causes of malfunction

If your washing machine does not have a self-diagnosis system, the following signs will help determine the problem:

- The drain program has started, but water remains inside the tank.

- An extraneous sound is heard when pumping out liquid.

- The water leaves very slowly, some remains in the tank.

- The equipment turns off until the drain is completed.

- The control board freezes while draining water.

- The pump hums, but the liquid is not pumped out.

If the user detects at least one or two such signs, this means that the pump has become unusable. To eliminate other possible breakdowns, it is necessary to check the drainage system - hose and filter - for blockages. If there is no debris in them, then you need to disconnect, remove the pump, disassemble, clean or replace it.

The most common causes of pump failure are:

- Wear of motor bushings.

- Short circuit or break in the motor winding.

- Blocked or broken impeller.

Pump design and types

Before you start repairing the pump, you need to know what type it is and how it works.

Depending on the manufacturer and model of the washing machine, the following types of pumps are known:

- Circulation. Used on expensive equipment manufactured by Bosch or Hansa to pump water during washing.

- Drain. Used to drain dirty liquid into the sewer. Its productivity can reach 20 liters per minute, and its power can range from 20 to 30 W.

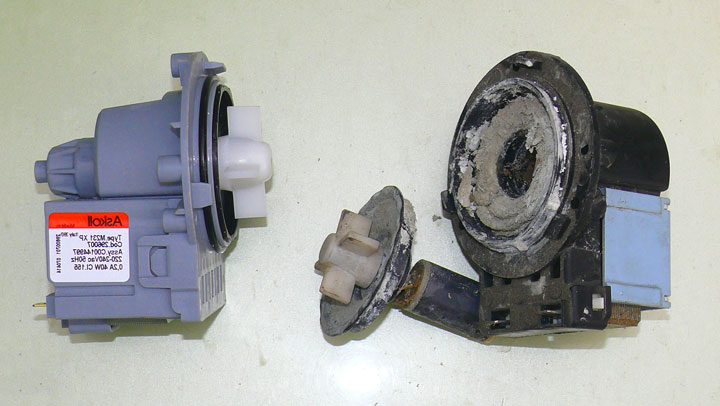

The drain pump design is very simple. It includes a motor with an impeller and a plastic pipe. The latter is attached to the engine on one side, and a drain filter is installed on the other side. This means that disassembling the pump for cleaning and maintenance will be easy.

Installation location and dismantling of the drain pump

To remove the faulty part, you need to determine where the pump is located in the washing machine and understand how to get to this unit and disassemble it. The location of the pump depends on the brand of washing machine.

- On equipment manufactured by LG, Candy, Ariston, Whirlpool, getting to the faulty element is very easy. It is necessary to turn the device on its side and remove the pan, if present, after which the pump will be visible and can be removed and disassembled.

- On Electrolux and Zanussi washing machines this process is a little more complicated. It is necessary to turn the equipment around with the back side, unscrew the screws and remove the back cover.

It is most difficult to disconnect the pump on Bosch and Siemens equipment. For these devices, you will need to partially disassemble the washing machine - remove the control panel along with the front wall.During disassembly, take photos of each part before disconnecting, it is especially important to take photos of the wiring before disconnecting. This will help to avoid mistakes during subsequent assembly. To get to the pump, you need to do the following:

- Unscrew the screws, remove the top cover.

- Pull out the powder tray.

- Unscrew the screws behind the tray and from inside the washing machine, photograph and disconnect the wiring, disconnect the control panel and put it aside.

- Open the hatch, pry the clamp with a screwdriver and remove, tuck the cuff inside the tank.

- Unscrew the fastener holding the UBL, disconnect the wiring, take out the part.

- Disconnect the base panel, unscrew the screws behind it.

- Remove the front wall.

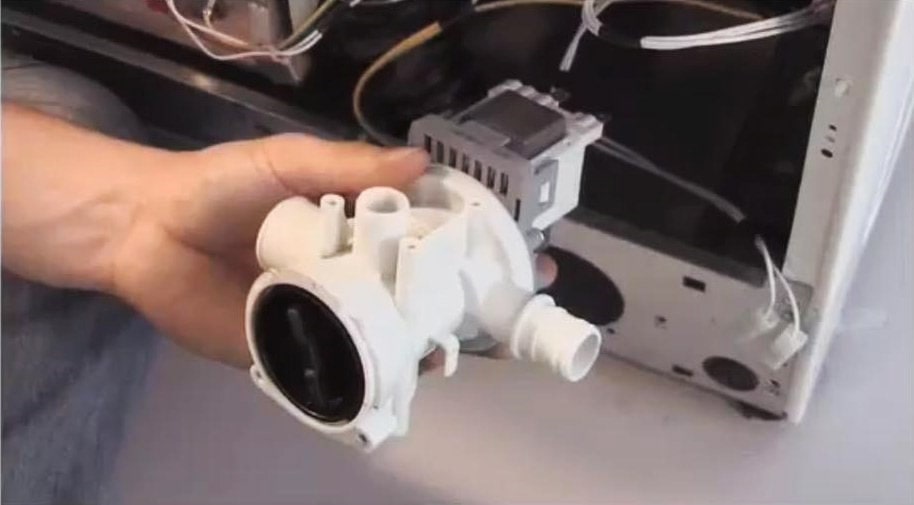

To remove the pump, you need to disconnect the wiring, unscrew the fasteners and loosen the clamps. If the part is held by latches, you need to press them down.

Pump repair and replacement

- After the part is disconnected, you need to check the washing machine pump. Before disassembling the part, you should inspect the impeller and all the holes and make sure that they are not clogged, hair, threads, wool and other debris are not wound on the blades. You need to pull out the drain filter and inspect the part visually, and then try to turn it. A serviceable unit should turn with pauses due to the coil installed on the magnet. If there is no debris, the impeller rotates with difficulty, the device will need to be disassembled. To do this, you need to:

- Remove the pump cover by unscrewing the fasteners or turning it counterclockwise.

- Pry off the latches of the impeller housing to disconnect it.

- If the crosspiece does not give in, you need to warm up the tail with a hair dryer, and then pry it off with a screwdriver.

Remove and clean the magnet with the impeller.During disassembly, you should take pictures of each part before disconnecting, it is especially important to take pictures of the wiring before disconnecting. This will help prevent errors during subsequent assembly. To get to the pump, you must do the following:

- Unscrew the screws and remove the top cover.

- Pull out the powder cuvette.

- Unscrew the screws behind the cuvette and from inside the washing machine, take a photo and disconnect the wiring, disconnect the control panel and put it aside.

- Open the hatch, pry the clamp with a screwdriver and remove it, tuck the cuff inside the tank.

Unscrew the fasteners holding the UBL, disconnect the wiring, and remove the part.

Detach the base panel and unscrew the screws behind it.

Remove the front wall.

To remove the pump, you need to disconnect the wiring, unscrew the fasteners and loosen the clamps. If the part is held in place by latches, you need to press them out.

Pump repair and replacement