Stopping the washing machine drum during operation is one of the most common reasons for contacting a specialist service center. Frequent reasons why the drum of a washing machine does not spin are: ingress of foreign objects, overload, mechanical damage, motor failure, incorrect operation of electronics.

Each breakdown requires mandatory diagnostics and subsequent repair by a highly qualified specialist. Otherwise, you will have to forget about the normal operation of the automatic washing machine.

What should you do immediately if the washing machine drum stops spinning?

The first step is to turn off the power to the washing machine by removing the plug from the outlet. Next, you need to drain all the water from the drum. This is done using a special drain hose, which should be located next to the drain filter.

It is worth noting that not all washing machine models are equipped with an emergency drain hose. If it is absent, it is necessary to empty the drum of water using a drain filter, under which, before performing this procedure, you should place a container to collect the liquid.

At the next stage, you need to find out when the washing machine stopped functioning fully (at what period of time its drum stopped spinning). This can be determined by the condition of the things in the drum. If there are residues of soap suds on the laundry, this means that the machine drum has stopped rotating during washing. If things are wet, then the problem occurred during the spin stage.

Possible causes of malfunction

In order to determine the reason for the washing machine drum stopping, you need to remove all the items from it and then try to spin it by hand. If the drum remains stationary, do not force it to turn, as this will only make the problem worse.

If you need to apply some force to turn the drum of the washing machine, and some extraneous noise is heard, it is possible that the reason for the stop was a foreign object that got into the tank. For example, it could be a torn button or accidentally forgotten change in your trouser pockets.

If the drum rotates freely, in this case the reasons for its stopping may be problems with the electronics, failure of the electric motor or drive belt. In addition, there are many different reasons that cause the washing machine drum to stop during operation.

Drum overload

This is observed with inexpensive washing machines, since they almost always do not have a sensor for monitoring drum loading.More expensive models notify the user of overload with a corresponding signal (sound or graphic information) and do not start until the weight of the laundry is correctly adjusted in accordance with the parameters set by the manufacturer.

In addition, the process of balancing the laundry in the drum may be disrupted when starting the washing process. To put it simply, all things are collected in one lump, after which the alignment is disturbed (for example, shirts and towels end up in the duvet cover).

This causes increased vibration, which the electronic control system of the machine positions as an error. As a result, the washing process stops and the drum stops.

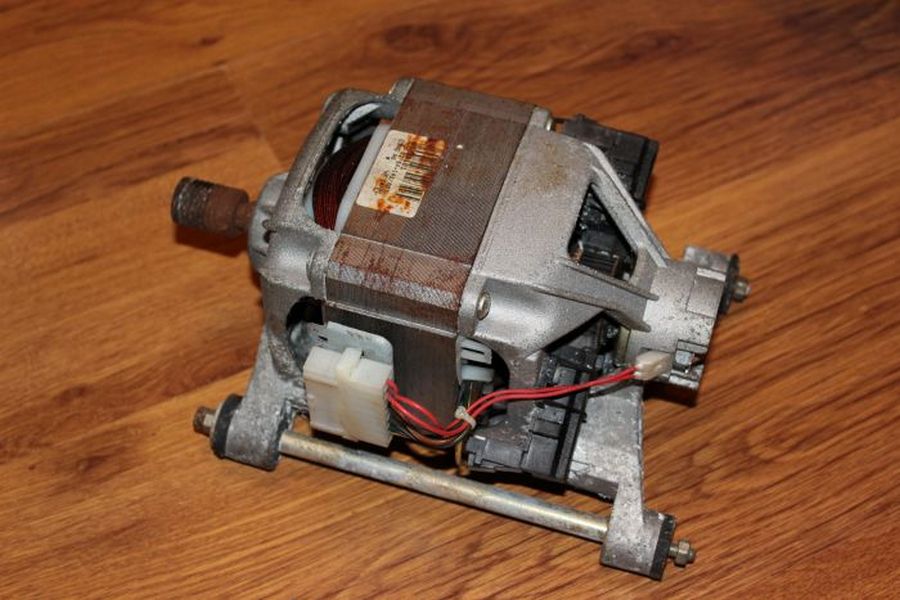

Electric motor failure

This malfunction consists in the absence of the sound of a running engine after turning on the machine and selecting a washing program. Here are the main reasons for this breakdown:

- wear of graphite brushes;

- break in the electric motor winding;

- lack of contact between the triac and the motor in the electric motor control system;

- mechanical damage to the engine, which prevents its full functioning;

- failure of the engine protection system against voltage surges;

- an error in non-volatile memory that causes the drum to fail and stop during operation;

- violation of the integrity of electrical wiring;

- lack of power to the electric motor;

- failure of the triac in the power supply system to the electric motor terminals;

- malfunction of the power controller processor;

- other problems.

Diagnosis of faults and repair of the electric motor of a washing machine should only be trusted by an experienced service center specialist.Under no circumstances should you try to restore the operation of the electric motor yourself, since any incorrect actions will only aggravate the breakdown. It is quite possible that the malfunction is minor, for example, wear of the brushes.

Presence of a foreign object in the washing machine

One of the common reasons why the drum stops is the presence of small foreign objects between the drum and the washing machine tub. These can be any small items that the user has forgotten in his pockets, buttons that have accidentally come off, or small things that fall into the space between the drum and the tank through the rubber seals.

Their presence is accompanied by extraneous noise during operation of the washing machine.

Such objects can completely block the drum during operation, so they must be removed without fail. This should be done only after the washing machine has been completely de-energized.

The easiest way to get into the space between the tank and the drum is from the side of the heating element, which must first be dismantled to ensure full access.

If you cannot remove the source of the noise, you will have to completely disassemble the tank. This may pose some difficulties, since most budget washing machines are produced with non-separable tanks. In this case, you will have to use the services of a service center, since in order to completely eliminate the malfunction it will be necessary to saw the tank and then restore its integrity (sealing). If the foreign object is not removed, it may damage the tank or drum beyond the possibility of further repair.

Motor brush wear

In any electric motor, brushes are consumables that must be periodically replaced due to natural wear and tear. The spent brushes completely cease to perform their function: to provide the necessary contact to create an electromagnetic field, due to which the rotor rotates. During operation, they gradually wear out, resulting in reduced contact. If you have certain knowledge, tools and skills, you can replace the brushes yourself, completely eliminating the described malfunction.

In order to replace worn brushes, it is necessary to dismantle the electric motor. Next, the electric motor should be placed on the table so that the brush commutator is at the top. We disassemble the brush seats and remove the worn elements. For most budget washing machine models, finding suitable brushes for the electric motor is quite problematic. In this case, we recommend contacting the manufacturer’s specialized service center.

The drive belt is faulty or loose

If you can clearly hear the sound of a running electric motor, but the drum does not rotate, the reason for this may be the drive belt, which can weaken, fly off, or completely fail. To assess its condition, you need to remove the back cover of the washing machine. There is one nuance here for certain models: in order to remove the back cover, you will need to unscrew the top one.

Let's move on to inspecting the condition of the drive belt. The presence of cracks and signs of wear on it is a prerequisite for urgent replacement, otherwise the belt may break during operation, which can seriously damage the elements and components of the washing machine located next to it.

If the belt comes off, it must be returned to its original position. This is quite easy to do. It is necessary to put one end of the belt on the electric motor pulley, and the other on the large pulley, and then turn the drum a little so that the belt takes its original position. During this procedure, be careful not to twist the belt. Otherwise, after starting the machine, the procedure will have to be repeated. We recommend replacing the loose belt with a new one.

The electronic module or programmer is faulty

This is one of the most common reasons why the washing machine drum stops spinning. Moreover, it manifests itself regardless of the brand, model and cost of household appliances.

The programmer (electronic control unit) is the main system that reads information from all sensors of the washing machine and processes commands, on the basis of which it launches the corresponding washing programs. In addition, the electronic module is fully responsible for the safe operation of the washing machine, blocking its operation if certain errors are detected, for example, there is too much laundry in the drum.

Common causes of malfunction of the electronic control unit are damage to the wiring or contact pairs. The board itself may also be damaged due to mechanical impact or voltage drop.

Troubleshooting and restoring the programmer's functionality should only be carried out by a highly qualified specialist who is well versed in electronics, thoroughly knows the structure and operating principle of all modules of the washing machine, and also has good soldering skills.The best option, if the ECU fails, is to completely replace it with a new or used one. But this is far from a budget-friendly way to restore the functionality of a washing machine. It is much cheaper to replace a failed capacitor or solder the contact track on the programmer board.

Problems due to bearing failure

In the event of a bearing failure, the following is noted during operation of the washing machine:

- The load on the drive increases significantly.

- Drum play.

Due to the increase in friction force due to the destruction of the bearing block, a large amount of metal shavings is formed, which oxidizes under the influence of water. As a result, the surface of the drum becomes covered with red streaks, which is evidence of bearing failure. Wear of bearing pairs is accompanied by increased vibrations of the drum and incorrect functioning of the washing machine. For example, the spin program may not work well due to a decrease in drum speed.

Complete destruction of the bearing makes further operation of the washing machine impossible, since the drum in this case cannot rotate at the speed set by the washing program or remains completely jammed. If the described symptoms of a malfunction are detected, an urgent replacement of the bearing block is necessary.

The doors opened in a top-loading machine

During the spin cycle in top-loading washing machines, the drum flaps may open due to overload or a malfunction of the lock. Let's describe the sequence of how to fix this problem yourself:

- Remove the side and rear panels.

- Disconnect the power wires, then unscrew the shaft mount.

- Close the doors.

- Remove the tank and drum.

We check the functionality of the latch by opening and closing the doors. If it fails, you must contact a service center to replace this element, since further operation of the washing machine is not permissible.

In what cases should you call a specialist to repair equipment?

Restoring the washing machine's functionality on your own can only be done if you have certain knowledge and tools. But any repair of washing machine units has certain nuances.

To diagnose and fix a malfunction, you need to have a good understanding of electronics, know the operating principle and structure of individual components of the washing machine, and have the appropriate tools. An experienced specialist knows all the nuances and features of the operation and repair of washing machines, thanks to which he can correctly eliminate any malfunction.

Only contacting a specialized service center for repairs is a guarantee of restoring the washer’s functionality, since such workshops have a staff of qualified specialists and all the necessary equipment. In addition, the user is provided with a guarantee. Therefore, you should not save money and trust the repair of your washing machine to “masters from the Internet” or try to do it yourself, as this can significantly aggravate the malfunction, up to the impossibility of further repair.

Preventive measures to help avoid breakdowns

To prevent the occurrence of malfunctions of washing machines during their operation, you should always follow the following rules:

- Be sure to read the operating instructions and fully adhere to everything written in it.

- Do not overload the drum.

- Do not machine wash large items that could damage the tank.

- Before putting things into the drum, be sure to check all pockets for the presence of small third-party objects (changes, keys, etc.).

- Be sure to thoroughly clean your washing machine. This activity must be performed at least once a year. To clean, fill in a special cleaner and run the machine without laundry, selecting the program with the highest temperature setting.

- Use special bags for washing small items of clothing and women's underwear.

- Monitor the technical condition of the automatic machine.

- Correct minor faults in a timely manner.

If during operation of the washing machine there are power outages and power surges, it is necessary to stop the washing process and turn off the power to the equipment.

In case of constant power surges, it is recommended to use special stabilizers, otherwise there is a risk of complete failure of the washing machine without the possibility of further restoration of its functionality.

To maximize the service life of your washing equipment, you must always keep it clean. You should also monitor the condition of the main controls. For example, all keys should be pressed without effort. You should periodically clean the washing machine control panel from dirt and grease.

After completing the wash, be sure to drain the remaining soapy water through the outlet filter (if so provided by the design). After completing the wash, you need to wipe the drum dry and turn off the power to the machine.

General rules for caring for washing equipment

After completing the wash, the following sequence of actions must be performed:

- Clean the powder and detergent tray. You can use an old toothbrush for this.

- Be sure to wipe the drum, loading hatch cover and all rubber seals dry.

- Remove all small debris that accumulates in the drum during the washing process.

- Periodically monitor the condition of the drain filter and clean it when dirty.

Bottom line

Various malfunctions cause the washing machine drum to stop during operation. Moreover, each of the problems must be eliminated at the stage of its occurrence, otherwise, the cost of repairs can be commensurate with the price of a new washing machine. Only competent operation of the equipment in compliance with all the manufacturer’s recommendations will completely avoid the occurrence of various malfunctions, the elimination of which will require contacting a specialized service center.