If a problem occurs, the Gorenje washing machine performs a self-diagnosis. An error code is displayed on the unit display screen. With its help, you can find out the node that led to the malfunction. Error E3 in a Gorenje washing machine indicates insufficient water level in the tank.

Decoding error code E3

The appearance of code E3 indicates that the water level does not meet the minimum value. The washing machine should fill the tank within 4 minutes. After a timeout, the corresponding error is displayed.

If you are unable to fill the tank, you need to pay attention to several components:

- water level sensor status;

- pipes;

- a valve responsible for pouring water into the container;

- electronics.

Causes of error E3

Lack of water can be associated with several faults:

- Error code E3 appears due to kinking or squeezing of the inlet hose.

- The performance of the unit depends on the condition of the drain system. In the event of a malfunction, the water immediately flows into the sewer. The washing mashine owner can hear the characteristic sound of fluid draining.

- Loss of tightness is another factor that prevents the completion of the water collection cycle. In this case, you can see liquid on the floor.

- When error E3 appears, you need to check the status of the sensor that sends water level data to the control module. If there is little liquid in the tank, the system refuses to start the wash cycle.

- The cause of equipment malfunction may be a board failure.

Taking too long to draw water indicates possible problems. The weak point of the drainage system of Gorenje washing machines is the pipe. During operation of the unit, deformation of the part may occur. Reasons for pipe failure include poor quality material, ingress of foreign objects and the use of aggressive liquids.

As a result, the unit becomes deformed and punctures and cracks appear on its surface. If defects are detected, the pipe must be replaced.

How to restore the machine's functionality with your own hands

It is not necessary to call the specialist right away. Minor faults can be fixed with your own hands.

Make sure there is water in the system. Weak fluid pressure is one of the reasons for machine malfunction.

How to clean the filter mesh

Carefully inspect the edge of the tee. There should be no obstacles. Check the condition of the filter located on the inlet valve. The problem with fluid collection may be due to a blockage. Before starting repairs, disconnect the unit from the power supply. Be sure to turn off the water.

The problem with fluid collection may be due to a blockage. Before starting repairs, disconnect the unit from the power supply. Be sure to turn off the water.

Loosen the clamps that hold the inlet hose. Now you can pull it out and inspect it for damage and dirt. Remaining water from the system will fall on the floor. Therefore, you need to prepare a rag in advance.

After this, you need to clamp the filter with pliers and pull it towards you. Often a strong scale forms on the mesh. You can get rid of salt deposits using citric acid. Place the mesh in the solution for approximately 30 minutes.

At the final stage, you need to rinse the filter under strong water pressure. Now you can install the filter and hose in place.

After repair, run an express wash. In this way you can verify the functionality of the unit.

To prevent re-clogging, it is recommended to install an intermediate filter.

The intake valve has failed

The water intake process is regulated using the fill valve. In this case, the current is supplied to the coil, which is necessary to create an electromagnetic field. In this way you can regulate the operation of the shutter.

After reaching the required liquid level, the control module gives a signal. The electrical supply to the valve coil is cut off and the valve closes.

The element is located under the top panel of the washing machine at the back wall. The device must be checked for mechanical damage. Contaminated contacts of the part must be cleaned. If a blockage is detected, the hose must be flushed.

To diagnose the intake valve, you will need a multimeter, which must be set to measure resistance. Attach test leads to each winding. The resulting values should be about 3 kOhm.

Deviations indicate a device malfunction. Of course, you can try to replace the burnt out winding. However, this method does not guarantee restoration of performance. It is much easier to purchase a new valve.

To replace a failed unit, you need to perform the following steps. First, unscrew the bolts that secure the device.After this, install the new intake valve.

Faulty electronics and pressure switch

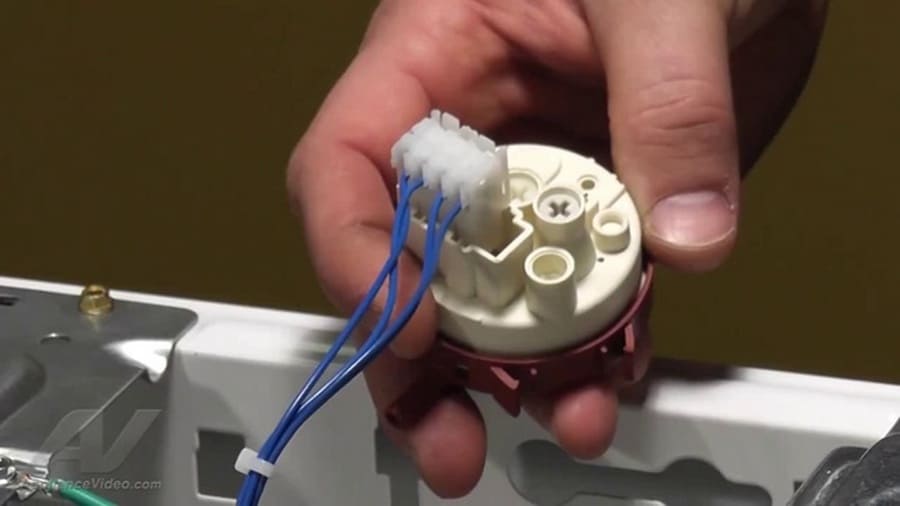

Most often, the pressure switch, which is responsible for the water level in the tank, breaks down. To check its functionality, just remove the top panel and find a small disk. A tube is attached to it, which serves to collect water in the tank.

The sensor monitors the water level in the machine and sends a signal to the control board. To check the condition of the pressure switch, you need to disconnect it. Using a multimeter, test the contacts.

The appearance of error code E3 may be due to electronic malfunctions. To resolve the electronics failure, you can try to restart the controller. For this purpose, it is necessary to turn off the power to the washing machine for 10-20 minutes. Now all you have to do is plug the unit into a power outlet and try to restart the washing program.

There are several factors that lead to electronic failure:

- Pay attention to the humidity level in the room. Operating the unit in such conditions can lead to damp contacts. In this case, it is necessary to dry the microcircuit and get rid of oxides.

- Voltage surges pose a danger.

- The power cord has become kinked. There should be no mechanical damage on the cable.

Check the board for short circuits. For this purpose, it is necessary to call all contacts. Electronics failure may be due to failure of resistors and diodes.

You can see darkened traces on the board. Pay attention to the change in color of the legs and the condition of the capacitors. Experienced owners can restore the operation of the unit on their own. Microcircuits must be cleaned of dirt and carbon deposits.

You can repair the board yourself only after the warranty period has expired.If necessary, you can re-solder the burnt tracks. If you lack experience, it is best to contact a service center.

Prevention

To avoid error E3, you can use several tips:

- An increased level of salts in tap water is one of the reasons for the appearance of limescale in the system.

- Use products that soften the water.

- Problems filling the tank may be due to the filter. It is necessary to regularly clean the mesh from dirt.

Conclusion

The appearance of error code E3 indicates problems with water intake. Loss of performance may occur due to leaks in the system. Be sure to check the condition of the pressure switch and the board. During operation, dirt that is present in tap water gets into the filter. A clogged mesh is one of the reasons for unit failure.