A washing machine is a device without which many cannot imagine life. Typically, washing mashine owners expect that the equipment will work for at least 8-10 years, but not everyone understands that the machine needs careful handling and timely maintenance. The most important element of the machine is the oil seal. The service life of washing equipment largely depends on it. In this article we will try to figure out why lubricant is needed for the oil seal of a washing machine and how to choose it.

A washing machine is a device without which many cannot imagine life. Typically, washing mashine owners expect that the equipment will work for at least 8-10 years, but not everyone understands that the machine needs careful handling and timely maintenance. The most important element of the machine is the oil seal. The service life of washing equipment largely depends on it. In this article we will try to figure out why lubricant is needed for the oil seal of a washing machine and how to choose it.

What is an oil seal?

Washing machine - one of the household appliances whose operation is directly related to water. However, some elements should never come into contact with water, as this can lead to poor performance and equipment breakdown. The problem of isolating parts from water is solved by a seal, without which no one can do modern washing machine.

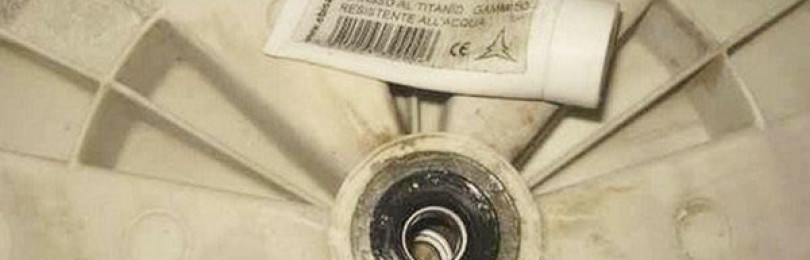

Washing machine drum is fixed on a bracket, which, in turn, usually has 3 or 4 legs. In the center of the bracket there is a steel axle shaft, the main task of which is to secure the drum housing to the bearing assembly. It is thanks to this design that the drum has the ability to rotate in different directions and at different speeds (this is necessary to implement different washing modes).

It is located in a special bushing, which is located in the center of the axle shaft. The main task of this part is to prevent moisture from coming into contact with the bearings. Its malfunction entails the appearance of rust on the bearings. In this case, the machine begins to make grinding sounds, and after a while it may begin serious problems at work.

The tightness provided by the sealing element is achieved due to the materials from which it is made. This is usually rubber, silicone rubber, fluorine rubber, or something else. There is a metal insert inside it, thanks to which the part retains its shape. Despite the fact that the insert is made of metal, it is extremely fragile, so when replacing and lubricating the oil seal you need to be especially careful.

During operation of the device, the machine shaft constantly interacts with the inside of the oil seal.

Lack of lubrication on the sealing part leads to increased friction, which results in rapid wear. Obviously, the tightness in this case will be compromised, and the safety of the bearings will be jeopardized. Grease for washing machine seals will help avoid the problem.

Where can I get lubricant?

It is best to purchase it in specialized stores that sell equipment for repairing household appliances. Often, washing machine manufacturers also produce lubricants, claiming that this particular lubricant is suitable for a specific brand of machine. In cases where the cost of such a lubricant does not allow you to purchase it, you can buy an ordinary one, it will be no worse.

Selection Criteria

In order for the oil seal to work for a long time and properly, it is necessary to choose the right lubricant.

The following criteria must be taken into account:

- Water resistance. If it is not waterproof, a solution of water and washing powder will wash it out of the sealing part in no time.

- Non-aggression. If the lubricant is too caustic due to certain chemicals in the composition, it can damage both the sealing element itself and the metal axle shaft.

- Viscosity. The liquid composition will simply flow out and be washed away with water; it will not be of much use.

- High temperature resistance. During operation, the sealing part heats up, so the lubricant must withstand temperatures of 180-200˚C well.

Instructions

After the lubricant is selected and purchased, it must be used for its intended purpose. Lubrication is often carried out after replacing old seals and bearings.

First you need to disassemble the washing mashine. It is necessary to carefully remove the cover, and then remove the walls - front and back. Inside the washing machine there is a tank that needs to be disassembled into two parts. After this, it will be possible to get to the bearing assembly and the bushing with the seal.

The sealing part must be lubricated before installation, thus eliminating the possibility of it drying out and being damaged as a result of friction and exposure to high temperatures.

You need to handle it as carefully and carefully as possible so as not to break the fragile metal insert inside.

First, carefully lubricate the outer side of the oil seal with a thin layer. After this, it’s the turn of the inside. This will require more lubrication, because it is the inner side that is at risk of deformation. After this, the sealing part is installed in the bushing, and the machine is assembled.