This brand of Belarusian origin has earned a good reputation in the former Soviet Union. Numerous household appliances are produced under this brand. The list of this equipment also includes washing machines. Of course, the quality of this unit meets all the requirements imposed by the standards. However, there are certain points that do not have the best effect on the operation of this model of household appliances. For example, very often error F13 in the Atlant washing machine causes housewives a lot of inconvenience.

This brand of Belarusian origin has earned a good reputation in the former Soviet Union. Numerous household appliances are produced under this brand. The list of this equipment also includes washing machines. Of course, the quality of this unit meets all the requirements imposed by the standards. However, there are certain points that do not have the best effect on the operation of this model of household appliances. For example, very often error F13 in the Atlant washing machine causes housewives a lot of inconvenience.

Therefore, let’s try to understand in more detail what this error is, and how an ordinary user can get out of this situation.

Abbreviation and explanation

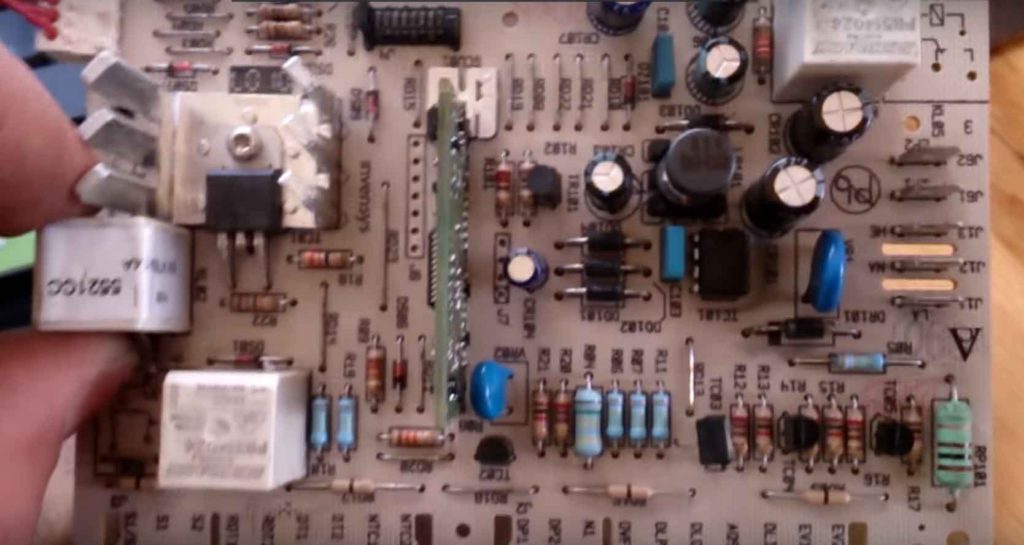

If we consider this device, it should be noted that it has a special display board, which usually provides the necessary amount of information on the operation of the machine. This is an excellent help option in a situation where, for example, the system responsible for self-diagnosis of the device displays an error code on the display. This helps to quickly understand what happened to the unit and how to get out of this situation.

If this concerns a code such as F13, then you just need to see it and open the technical documentation for the washing machine. This will allow you to understand the nature of the error and make it possible to understand what caused it to occur.

In a situation where there is no such screen on it, it becomes very difficult to understand what kind of breakdown is occurring. For this purpose, these washing machine models were equipped with an indicator panel. The indicators on it light up in a certain order, which signals the user about the presence of the corresponding type of error. If you carefully examine the set of indicators on the device panel, you can see that on the bottom row this type of error is indicated by burning lights of the first, second and fourth order, if you start counting from the left side.

It is interesting to look at the explanation that the unit manufacturer provides when this type of situation occurs. Thus, the documentation notes that we are talking about a faulty state of the control module. This may also indicate a faulty wiring that goes directly to this module.

With this formulation, several dozen breakdowns can be immediately attributed. This explanation is connected with the fact that a semiconductor component can create a problem, and there are a great many of them in the unit. However, don't despair. Upon closer examination of such a situation, one can understand that there is a way out, although not an easy one, from this situation.

Checking contacts and wiring

In order to check the module that controls the machine, you need to know that it is located in the front part of the unit. At the top right there is a special compartment where it is installed in close proximity to the pressure switch.

Thus, the bulk of the wiring and the chip itself that goes to the board of this module is laid on the right side wall of the case.If you look at the comments of specialists, they often express concern that this particular place in the machine was chosen for the module. In their opinion, such a presence causes frequent breakdowns in the unit.

- If we consider a front-loading device, then the part of its body from above is mainly subject to unwanted vibration. At the same time, installing such elements at the top is fraught with the risk that during, for example, spinning the unit, vibrating, it can hit the walls of the room. This accordingly leads to shaking of the module itself. Therefore, the chip and the wires in it will become loose.

- Situations are also often observed when housewives leave containers with detergents on the top panel of the device, which leads to spillage. In this case, the gel gradually flows down the wall and invariably penetrates into the device. This causes the contacts to gradually oxidize. As a result of this entire process, the module fails.

- In the main types of these units, such a module is located at the rear bottom on the right side. This allows you to ensure its maximum distance from the dispenser in which the washing powder is located. Therefore, in the model under consideration, this becomes a disadvantage, since the foam can very quickly reach this element of the machine. Then there is a situation of short circuit and failure of the device.

It should be noted that the listed disadvantages of this module installation location can be compensated by some advantages.

One of the main positive aspects is that it provides quick access to the master. Simply remove the cover and the module is already at hand, as they say.Then all that remains is to take a multimeter and begin the setup procedure. Initially, the wires are checked one by one for a break. If this malfunction is detected, it must be immediately eliminated by replacing the wire along with the contact. Sometimes bad weather happens, so it’s better to replace the entire bundle of wires when several of them fail at the same time.

After this, each of the contacts on the control unit is tested. If there are no breakdowns, you need to move on to the board itself.

Signs of module failure

If this error occurs, you can independently eliminate a number of possible problems. For example, there are a number of indirect signs by which you can find out that it is the unit module that is faulty.

- If, when connected to the SMA Atlant power supply network, there is no reaction in the form of an audio signal.

- When you press any of the keys on the control panel there is no reaction. There is no way to switch them, and the indicators themselves start blinking in a chaotic manner.

- The mode that involves a spin procedure does not cope with its tasks in full. In this case, the panel hangs, and the code indicating a breakdown may not be displayed.

- The system will help you hang at a certain frequency. For example, when starting a wash, water may not be drawn in. Even if it is collected, it is immediately drained.

- There is a situation when it can carry out the washing procedure for a long time, regardless of the mode that the user sets for it. In such a situation, it does not go into modes that include rinsing or spinning. Then the machine just freezes.

- When starting the washing process, there is no reaction from this module.

- When washing, a sudden change in the drum speed may be observed. It starts to rotate at a speed that does not correspond to the selected mode. At the same time, the direction of its rotation also changes.

- The element that is designed to heat water can greatly overheat it or not perform this procedure at all.

Thus, error F13 in the Atlant washing machine indicates a malfunction of the unit. In addition to the above points, this can be caused by several other situations.

- If sharp voltage changes are noted in the power supply network, which accordingly leads to overheating of the board.

- The presence of loose connections.

Therefore, it is recommended to start the device in automatic testing mode. This can be done by carefully studying the instructions.