Company from South Korea besides passenger washing mashines produces good automatic washing mashines for washing clothes. Like other household appliances, washing machines are at risk from frequent and sometimes improper use. Therefore, you should know the algorithm of actions to repair a Daewoo washing machine.

Company from South Korea besides passenger washing mashines produces good automatic washing mashines for washing clothes. Like other household appliances, washing machines are at risk from frequent and sometimes improper use. Therefore, you should know the algorithm of actions to repair a Daewoo washing machine.

Causes of breakdowns

Most often, malfunctions in a Daewoo washing machine appear due to careless handling of the household unit. Users ignore the manufacturer's recommendations, resulting in a non-working washing machine after several years.

In second place in the group of reasons is ordinary inattention. Before calling a repair specialist, it is recommended to independently inspect the wires and hoses and check the pressure in the water pipe.

There is another common cause of breakdown - failure of the electronics. In this case, repairing it yourself is impossible; you will have to call a specialist.

Basic errors of a Daewoo washing machine

For ease of use, the manufacturer provides self-diagnosis system. The Daewoo washing machine, which has an electronic control, will find a problem and inform the user about it by sending an error code to the screen.Semi-automatic models from Daewoo will give an alarm by flashing lights. To correctly navigate the malfunctions of a Daewoo washing machine, you need to know what a particular error code means:

- error O.E. – the peculiarity of the breakdown is the inability of the device to drain dirty water on its own. The problem may be due to a malfunction of the drain pump, damage to the wires powering the pump or their contacts. Do not rule out clogging of the drain filter element and other parts of the system. It also happens that the hose intended for draining is pinched or incorrectly connected;

- error I.E. – a breakdown does not allow the Daewoo machine to take in water, or this process is slow. The same error signal can be activated if you have not opened access to liquid from the central system, or the water pressure in the pipes is low. It is also recommended to check the water intake hose and inlet filter mesh for blockages. There is a small chance that your Daewoo washing mashine has a breakdown in the sensor that controls the fluid level. Problems with the solenoid valve or freezing of the hose that collects water cannot be ruled out;

- error UE - with this signal, the Daewoo washing machine reports that an imbalance has occurred in the drum. The reason for this breakdown is laundry that has bunched up in a ball. Also, a similar alarm appears if the machine is not installed level. There are rare cases when a breakdown is associated with a violation of the integrity of the counterweight;

- error L.E. – this signal will tell the owner of the washing mashine that the loading hatch door is not closed tightly, or a breakdown has occurred in the locking device;

- error E8 – with such a signal, it becomes clear that the breakdown must be looked for in the loading sensor, due to which the washing machine does not start working;

- error E9 – look for a breakdown in the liquid level sensor or relay. You will have to check the pipes and all connections for tightness. It is likely that the pressure switch has also failed and will have to be replaced with a new analogue;

- error H6 - this error code is associated with a breakdown of the electrical circuit of the water heating element. There is also a possibility that The heating element itself also failed. It should be noted here that if you own a Daewoo air-bubble washing machine, then the latter option of failure will not threaten you. Units of this type do not have water heating devices.

Typical breakdowns

Taking into account the above basic errors, it becomes possible to quickly identify the most problematic areas of the Daewoo machine. As a rule, users of such devices turn to service centers for help with the following breakdowns:

- electronic board flew off. The machine can confirm such a breakdown by stopping the washing process or by prolonged execution of a given program, or by refusing to perform a spin cycle;

- malfunction of the sensor that controls the water level. There may be a blockage in the filter;

- failure of the temperature sensor. The water does not heat up well, and the washing machine may stop during operation;

- drive belt wear;

- The water heating element is not doing its job due to the formation of a large amount of scale or corrosion;

- the cuff made of rubber material burst, and water is leaking from the hatch.

Hazardous factors contributing to breakdowns

Anyone who operates a Daewoo automatic washing mashine is advised to know the reasons why breakdowns occur in most cases. By completely eliminating possible factors, you can extend the operating life of the washing device. For this:

- monitor the natural wear and tear of machine components and assemblies;

- check the quality of the water used for washing;

- use high-quality detergents;

- Prevent exposure to power problems.

We repair typical breakdowns ourselves

Let's consider the procedure if you decide to carry out repair work on your own.

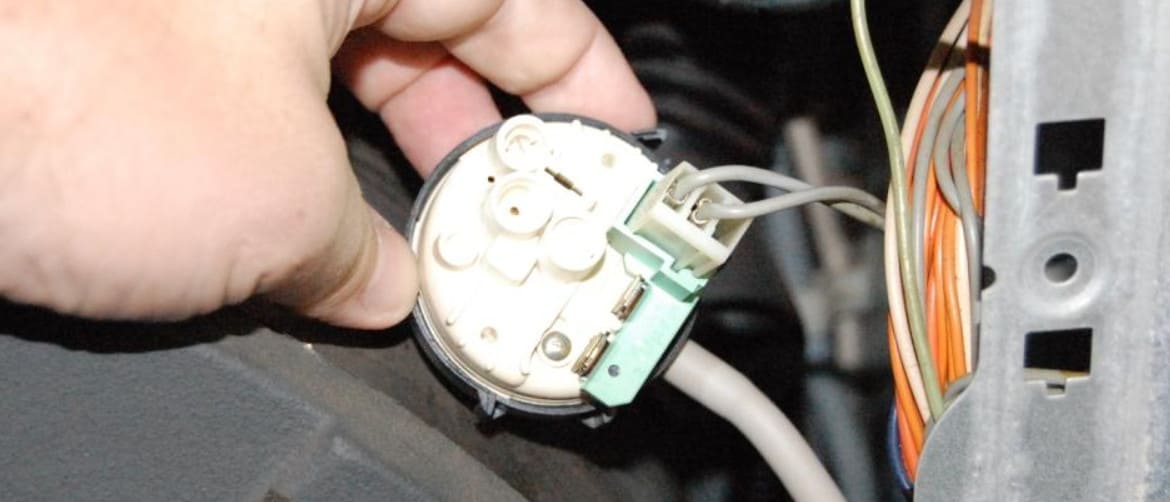

We check the pressure switch and replace it

When the water supply to the Daewoo washing machine stops, or its intake is slow, you should check the sensor responsible for its level. You will have to perform several operations:

- the washing machine is disconnected from the electrical network;

- remove the top cover from the body part by unscrewing a pair of mounting bolts from the back and sliding the panel back to remove it from the body;

- For many washing mashine models, the sensor is located on the wall, near the top panel. Having found the element, remove the pipe from it, held by a clamp, which is unclenched using pliers;

- the water intake hose needs to be replaced. After installing it, blow it out so that clicks appear, confirming the contacts are activated;

- All tubes are inspected for damage. If necessary, they should be replaced or cleared of blockages. If completely stuck, the sensor changes completely.

Cleaning the filling system of a Daewoo washing machine

This operation is performed in two stages - the filler filter and the hose itself are washed. It is recommended that the work be carried out comprehensively. To do this, turn the washing machine around with its back wall and install it in the center of the room. After this, the water intake hose and filter mesh are removed. The hose is inspected for integrity and washed to remove debris. The cleaned mesh is installed in place, the sleeve is attached, and the test wash is activated. If the damage persists, the inlet valve will have to be replaced.

Conclusion

Other typical breakdowns are eliminated, as in other brands of washing machines. It would not be superfluous to remind you that before repairing Daewoo wall-mounted washing machines, they should be removed from their installation site and placed on the floor.