Gorenje washing machines are popular not only in Russia and the CIS countries, but also in Europe. But practice has repeatedly proven that even the best models of this technology periodically break down. In such cases, diagnostics should be performed to identify specific causes of failure. It should be noted that most often the repair of Gorenje washing machines can be carried out on your own, or you can invite an experienced specialist from the service center.

Gorenje washing machines are popular not only in Russia and the CIS countries, but also in Europe. But practice has repeatedly proven that even the best models of this technology periodically break down. In such cases, diagnostics should be performed to identify specific causes of failure. It should be noted that most often the repair of Gorenje washing machines can be carried out on your own, or you can invite an experienced specialist from the service center.

Basic malfunctions of the Gorenje washing machine

The manufacturer of washing machines, Burning, knows very well how to make its product attractive. And even today, when there are a sufficient number of high-quality models from other brands, you can purchase a completely unique Gorenje washing machine.

To understand how to repair such units yourself, you need to understand the most common failures that appear in machines of this brand. Their list is compiled on the basis of statistical data provided by the main service centers in Russia:

- In most cases, problems arise with the water drain pump. Almost a quarter of consumers contact repair shops due to pump failure;

- in the second position there is a water heating element;

- Then there are problems arising from failures of drain pipes;

- complete the list of main electric motor brush failures.

With a small gap from the top four, the door handle of the washing mashine breaks down. But a problem of this nature can be easily resolved; there is no need to describe the order of work. All work consists of finding an analogue and replacing it.

Gorenje washing machine repair

If you correctly determine the causes of failures of a laundry washing unit, then repair work can be carried out on your own.

- Repair of the pump responsible for draining waste water.

Pumps fail quite often when compared with other units. It should be noted that Gorenie brand washing machines have increased sensitivity to water with a large amount of impurities. The moving units are located at a close distance, and if water stone begins to settle on them, it simply interferes with normal operation. Parts wear out much faster, and eventually the pump breaks and needs to be completely replaced. All work is carried out in the following sequence:

- the machine is disconnected from the electrical network;

- The tray intended for detergents is removed and the remaining water is poured out of it. After this, the tray can be replaced;

- the machine is placed in a comfortable position;

- access to the pump is more convenient through the bottom of the machine, so it is recommended to turn it on its side;

- models of washing machines of this brand are covered on all sides with protective panels, so you will have to unscrew the screws to remove the bottom cover;

- visually inspect the pump and check its serviceability. To do this, you will need a tester with which the resistance value is measured.Before taking readings, all wires must be disconnected. If the device shows 160 Ohms, then the pump is in perfect order. Otherwise, it will have to be replaced;

- to remove the pump, you need to unscrew all fasteners;

- a new original analogue is purchased in the store, which is installed in place of the old pump. The necessary wiring is connected to it;

- The machine cover is put back in place, the machine is returned to the vertical position and checked for functionality.

If you decide to do this work yourself, carefully check the pump with a tester. In case of the slightest error, you can dismantle and throw away a completely serviceable element, wasting money on purchasing a new one.

- Failure of the water heating element.

The heating element is the weakest point for any washing machine. And there are reasons for this:

- impurities in the water that form a limescale deposit on the heating element, after which it loses its ability to work;

- problems with the electrical network, expressed by voltage surges and other failures;

- violations allowed under operating conditions of the washing machine.

In any case, if the machine does not heat the water, then we can talk about a failure of the heating element, which should be checked first. To replace the heating element yourself, you must first prepare the machine for work - disconnect it from the power supply, water supply and sewer system. Now you can turn the unit with the back panel towards you and find the service hatch. After unscrewing the screws, it must be opened. A heating device will appear before your eyes, but to make it easier to work with, you will have to remove the drive belt from the pulley. After this, disconnect the wiring from the contacts.

It is recommended to mark them so as not to accidentally confuse them during connection. Now we need an ohmmeter, with which we check the resistance reading of the heating element. Probes are installed on the outer contacts; in operating condition, the heating element will produce a resistance of 10 to 30 Ohms, taking into account its own power. For other indicators, the element must be replaced. If the heating element is working properly and there are problems with water heating, you should check the thermistor and the wiring connected to these two elements.

What should you do to remove the heating device from the tank of the machine:

- the fastening nut securing the heating element is unscrewed. It is located in the center, between the contacts of the heating element;

- press on the fastening bolt and tear off the heating element from the mounting socket. You must act carefully so as not to damage anything;

- holding the contacts with our hands, we begin to swing it in different directions and carefully pull it towards ourselves. If all else fails, you can treat the edges with WD-40 and repeat the operation again;

- When the old heating element can be removed, do not rush to install a new analogue. You should check the hole with your fingers and remove any accumulated debris;

- After cleaning the seat, you can install the water heating element. It should be inserted into the groove and make sure that it is installed tightly;

- tighten the fastening nut, but do not tighten it too much, so as not to damage the thread;

- the wiring is connected, the drive belt is put on;

- Having closed the service hatch, we install the washing machine in place, connect it to all communication systems, and carry out the test.

- Failure of pipes.

Such a problem in a washing machine. Combustion is considered specific.Although the pipes are durable, they often wear out in the knee area. This happens, as a rule, for three reasons:

- low quality materials. Cracks through which water leaks may occur due to manufacturing defects;

- a sharp object hits the knee;

- Too aggressive detergents are used for washing.

In this case, repairing the machine should begin with inspecting the hoses and pipes. First of all, we inspect the water drain hose, since this is a simpler job. But to inspect the pipe, you will have to disassemble the machine, getting to it through the bottom of the unit. You need to look for the pipe near the pump. The scheme of work is as follows:

- a new original analogue is purchased;

- the clamps securing the pipe are released;

- the element that has lost its integrity is removed;

- a new pipe is being installed, the clamps are tightened;

- Now the machine can be assembled and put in place.

During installation, ensure the tightness of each connection. But you should not over-tighten the fasteners, so as not to damage the new part.

- The brushes in the electric motor are worn out.

Another common problem in Burning brand machines. The main signs of such a failure are loss of electric motor power and slow rotation of the drum. A burning smell will appear from the machine, and a cracking sound will be heard while the engine is running. In addition, the diagnostic system can recognize brush wear and send error code F4 to the screen.

If such symptoms occur, the electric motor should be checked. There is a high probability that the problem lies there. To do this you will have to perform certain actions:

- open the service hatch located at the rear;

- after this, the drive belt is removed from the drum so that it does not interfere with the work of removing the motor;

- now you need to unscrew the bolts that hold the engine;

- going around the machine, remove the detergent tray, drain the remaining water in it, return the element to its place;

- lay the machine on its side, remove the bottom panel;

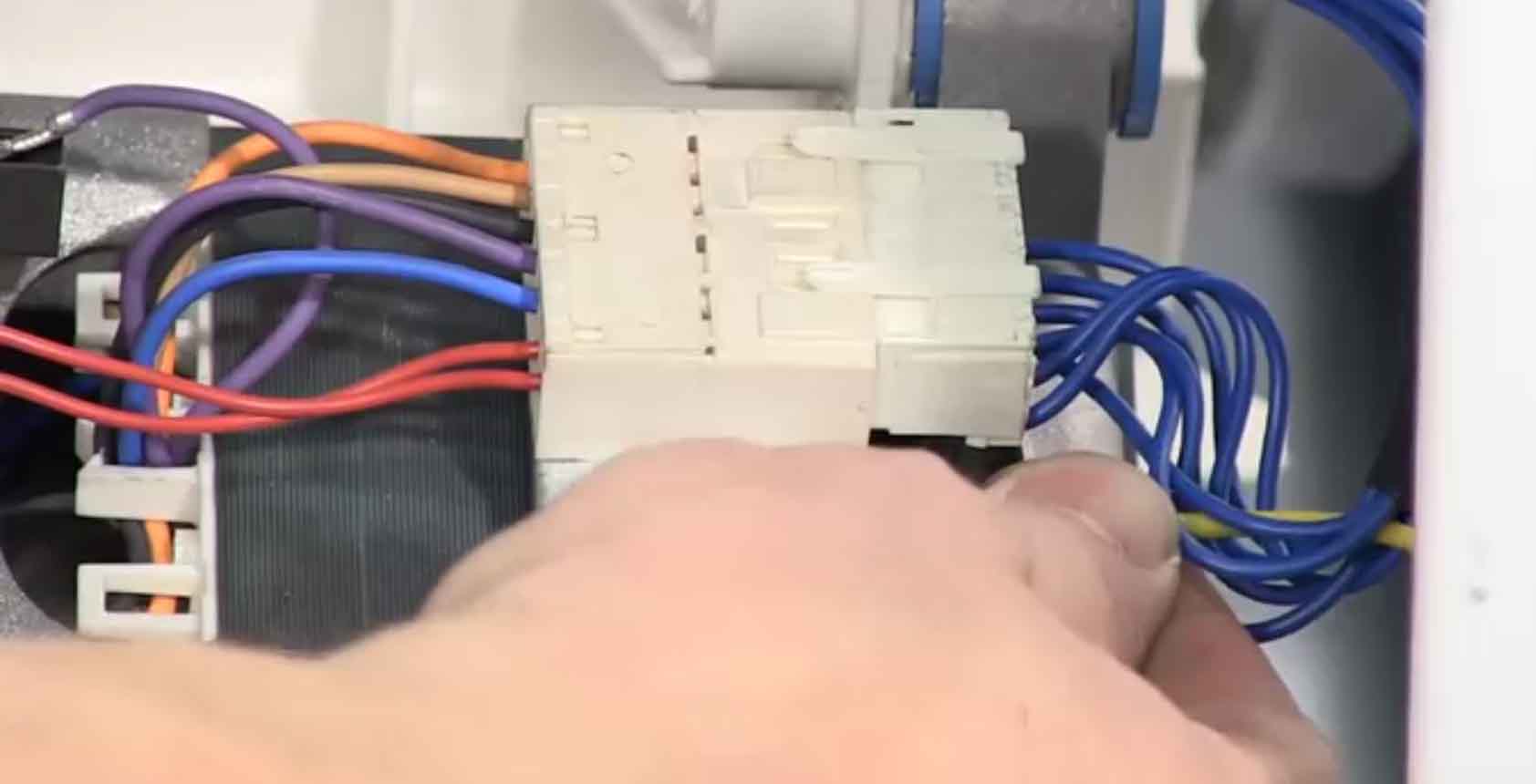

- disconnect the plug with wiring connected to the electric motor;

- remove the belt from the seat;

- All that remains is to remove the brushes from the motor and check them for wear. They will either be very worn out or smell burnt;

- New brushes are installed, the engine is returned to its place and fixed with fasteners, the wiring is connected, and the bottom panel is screwed on;

- the machine is installed in a vertical position;

- the drive belt is installed, the service hatch is closed;

- The machine is connected to all communications and checked for functionality.

Rules for operating the washing machine

The owner of a laundry washing machine is quite capable of eliminating violations in the use of the machine, thereby avoiding financial costs for service support. To do this, you must follow some rules, the main ones of which are the following:

- When washing, you must use only high-quality detergents;

- you should monitor the volume of things loaded into the drum of the machine so as not to overload it;

- the equipment must be used in a room with low humidity;

- Make sure that no foreign objects get into the drum during the washing process.

The washing machine has one distinctive feature that brings a certain ease of use.With its help, you can exercise independent control over most workflow functions. If any malfunction is detected, the unit itself will prompt you about the error, accompanying the prompt with a certain sound signal. The failure can be immediately identified by the error code and work can begin to eliminate it.

Help from professional specialists

Most often, it is recommended to contact a professional so as not to aggravate the situation with independent actions. Violations of repair work will only increase financial costs. Only a specialist can accurately determine the cause of the failure, select an original analogue, and perform all repair work.

But it also happens that symptoms do not always indicate refusal. Quite often, the cause of the error signal is a violation committed during operation. For example, water leaks through a poorly closed hatch. And the machine vibrates due to the fact that it is simply installed incorrectly, or the loading of things into the drum is uneven. Before contacting the workshop, you must make sure that even if all conditions are met, the unit is not working correctly. Having eliminated the probable causes caused by malfunctions, you can contact the workshop for help with repairs or advice.

Conclusion

It is recommended to treat the washing machine with care and watch for its attempts to generate failure signals. Some of the symptoms discussed will help you quickly resolve problematic issues. It is not always necessary to call a specialist, since quite often failures occur due to violations of the instructions. If it turns out that the Burning washing machine actually needs repair, then you should call an experienced technician.Remember that any wrong step you take can only bring additional repair problems.