Whirlpool washing machines are reliable, but they sometimes break down. Certified service centers can be found in almost any major city in the country, so there will definitely not be any problems with repairs and maintenance. Repair of Whirlpool washing machines can be entrusted to the specialists of the center, and if you have experience in such work, you can do it yourself.

Whirlpool washing machines are reliable, but they sometimes break down. Certified service centers can be found in almost any major city in the country, so there will definitely not be any problems with repairs and maintenance. Repair of Whirlpool washing machines can be entrusted to the specialists of the center, and if you have experience in such work, you can do it yourself.

Common faults and how to fix them

An automatic washing machine is a complex device; it consists of many components and assemblies, each of which can fail.The list of possible malfunctions of Whirlpool washing machines is very extensive; a complete repair manual will contain several volumes. The most common problems include the following: non-functional drainage, heating problems, wear or breakage of the cuff.

Water does not drain from the drum

Perhaps the most common problem that owners of Whirlpool washing machines may encounter. The machine stops and instead of draining the water, it displays an error message. There may be several reasons for a non-functional drain:

Washing machine drain filter

- clog in the drain pipe;

- the drain filter does not allow water to pass through;

- sewer is clogged;

- the pump does not work.

Before you begin repairing a Whirlpool washing machine with problems with the drainage system, you must remove the water from the drum. Especially for such situations, the manufacturer has provided an emergency drain. Removing water is simple; to do this, you just need to remove the plug, not forgetting to first replace the water container.

Once the water has been removed, you can proceed directly to the repair. The machine moves away for ease of operation. The hose is checked for contamination and kinks.

After the hose, check the cleanliness of the drain filter. It catches threads, scraps, and buttons, which can cause a blockage. It must be removed and washed. It is also a good idea to clean out the sewer using a flexible cable or bent wire.

If the filter is clean, there is no blockage inside the hose, and the machine still does not drain water, you should check the drain pipe and pump. To do this, it is necessary to partially disassemble the machine.

- The device is disconnected from the network, water supply and sewerage.

- The detergent tray is removed.

- The washing mashine is placed on its side.

- The bolts holding the bottom are unscrewed.

Having gained access to the pump contacts, the resistance of the windings is measured using a multimeter. If the device shows a break, replacement is necessary. The old pump is removed, the drain pipe is cleaned of dirt and scale. Having replaced the pump, the machine is assembled, connected to communications, and the drain operation is checked.

The heating element is faulty

If any program stops when trying to heat water, and the display shows a heating system error message, one of the most likely causes is a non-working heating element. It is basically impossible to repair a burnt-out heater; the only possible solution is replacement. In Whirlpool washing machines, changing the heating element is quite simple; you can do this procedure yourself.

- The machine is disconnected from the network and water supply.

- The device rotates or moves away from the wall for ease of operation.

- Use a screwdriver to unscrew the back cover.

- The bracket blocking access to the heater is removed.

Behind the bracket are the heating element leads and the contact pad. To check the heater it is not necessary to remove it, just disconnect the wires going to it.

To check the functionality of the heater, use a multimeter in resistance measurement mode. A non-working heating element will show infinite resistance, a working heating element will show several tens of Ohms, depending on the model.

A burnt heating element must be replaced. Perhaps the only difficulty that may arise during its replacement is rust. The screw that secures the heater can become so rusty that it is impossible to do without using special tools, for example, WD-40.

The old heater is removed, a new one is installed in its place, the rubber gasket should be replaced along with it, otherwise leaks are possible due to aging of the rubber.

Replacing the cuff

This is another common problem that is easy to deal with on your own. It manifests itself in the fact that during washing, water leaks through the cuff, the seal of the loading hatch of the machine. The reason for this phenomenon is the loss of elasticity of the cuff or its incorrect installation during the repair process.

Replacing the cuff is easy, you just need to follow a series of simple steps.

- Open the hatch all the way.

- Use a screwdriver to pry off the plastic holder

- Unscrew the fixing bolt, thereby releasing the cuff.

- Pull the cuff towards you.

- Carefully insert the new one. It is not recommended to use sharp objects to avoid damaging the thin rubber.

- Put on the clamp and tighten the bolt.

The cuff is a simple part, but the safety of washing depends on its quality. The right choice is an original part made in Italy or Slovakia. By buying a cheap fake, you will be able to save a little, but it is quite possible that you will soon have to disassemble the washing mashine again.

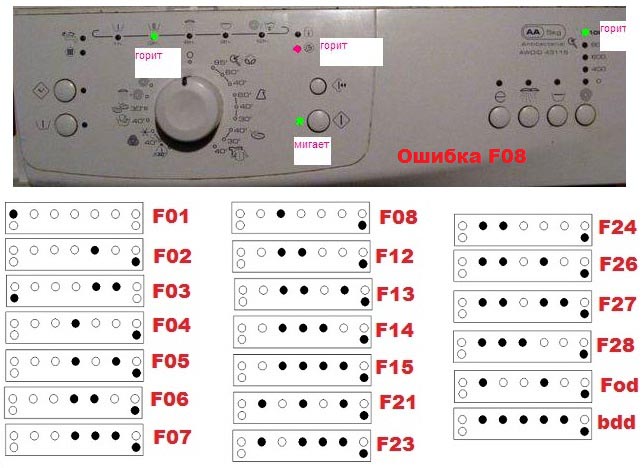

Whirlpool Error Codes

The list of malfunctions that you can deal with yourself is not limited to those described above. Knowledge of the machine's structure and the ability to understand its messages will allow you to solve most of the possible problems.

In any case, before you start repairing Whirlpool washing machines, you need to identify the malfunction and find its cause. The manufacturer has taken care of ease of repair; for this purpose, the firmware includes an automatic testing system, the result of which, in the form of an error message, is displayed on the indicator.

Problem with water getting into the machine.Errors: F01 (FH), F09, F13, F23

The first thing you should check when such errors occur is the presence of water in the water supply and its pressure. If the pressure in the system does not correspond to the nominal value, washing will have to be postponed until the water supply normalizes.

It is worth paying attention to the condition of the inlet valve. It contains a mesh that acts as a filter; if necessary, it should be washed or replaced.

If water flows into the machine normally, but an error still occurs, the reason may lie in the sensor that monitors the water level. It is worth checking the sensor itself, its connection, and possibly the control module.

The water supply is emergency shut off. Error F02 (FA)

This error may occur if the inlet valve is blocked. It must be checked and, if necessary, replaced. The same error may appear in the event of a water leak. It is worth carefully inspecting the installation site of the machine. If a puddle appears, the wash will have to be rescheduled until the problem is eliminated.

Problems with drainage. Error F03 (FP)

If the machine refuses to drain water, you need to check the entire drainage path. The reason may be a clogged filter, drain hose, or excessive bending. Such errors can be caused by a broken or clogged drain pump. In rare cases, the cause may be a controller malfunction.

Problems with water heating. Errors: F04, F05, F12

The machine does not heat water or its temperature parameters do not correspond to the values set in the program. The causes of this problem may lie in the heating element or temperature sensor. In any case, for repairs you will have to disassemble the device, test the heating element with an ohmmeter, and replace it if necessary. The same goes for the sensor.

Temperature sensor

There is no signal from the tachogenerator. Error F06

A tachogenerator is a small device that is installed on the engine to control its speed. Most often, the cause of this error is a spring washer that has flown off or a break in the conductors going to the device.

Motor controller problem. Error F07

The source of the fault is the controller board. To repair it, you need to remove it and replace parts that have failed.

Heating system problems. Error F08

The heater of a washing machine is one of its most vulnerable components. When in contact with water of poor quality, it becomes covered with scale, which significantly reduces its characteristics. This error may mean:

- the heater burned out or broke;

- The pressure switch does not work;

- controller is faulty;

- The temperature sensor is damaged or burned out.

To troubleshoot, it is necessary to disassemble the machine, check and, if necessary, replace the heating element or faulty sensor.

Problems with the electric motor. Errors: F10, F15, F26, F27, F28

The appearance of any of these errors indicates a failure of the electric motor or connection circuit. To eliminate them, you need to check the temperature relay and control triacs on the board. Burnt parts will have to be replaced.

Errors F27 and F28 indicate the impossibility of rotating the motor in the opposite direction and its rotation is too slow, respectively. To correct the situation, it is necessary to check and, if necessary, replace the reverse and winding switching relay.

Problems with motor windings are more difficult to diagnose. One or more windings may burn out, break in them, lack of contact, or insulation damage.In most cases, the engine will have to be replaced, the exception being worn commutator brushes.

Various communication problems. Errors: F11, F19

Most often, the source of these errors is the discrepancy between the parameters of the electrical network and the required values. It is necessary to check the voltage in the outlet and take measures to normalize it. It would be a good idea to use a stabilizer to connect the machine.

Control system malfunctions. Errors: F14, F16

Errors appear in the event of various malfunctions in the controller. To correct the situation, you may need to re-flash the module, or possibly replace it completely.

Also, the cause of errors may be hidden in faulty wiring, a break in one or more wires running from the control module to actuators and sensors. In this case, it is necessary to “ring” each conductor and, if necessary, replace the damaged one.

Wrong detergent. Errors: F18, Fod

The sensor detects an excessive amount of foam, which can cause machine failure. It is necessary to replace the detergent and repeat the wash.

Problems with the controller. Errors: F20, F21

The first of these errors appears if normal program execution is impossible due to a malfunction of the control unit, the second due to the impossibility of transmitting a command from the module to the actuators. To eliminate them, you need to disassemble the machine, check the integrity of the wiring and components of the controller board.

Violations in the water level control system in the tank. Error F24

The reason is that the pressure switch, the sensor that controls the water level, is not working. Replacement required.

Water level sensor

Firmware update problem. Error F31

This error indicates that an attempt to update via the Internet has failed. You may need to check your router settings or contact your provider.

Problems with the hatch. Errors: F31, FDU

The appearance of these errors indicates that the hatch is not tightly closed or the corresponding sensor is not working. You should try to open the hatch and close it again; if the error does not disappear, replace the sensor.

You can cope with most breakdowns of a Whirlpool washing machine at home. To do this, you only need a small set of standard tools, the ability to use them and, of course, desire. Of course, you should not try to repair a machine whose warranty period has not yet expired, and you should not undertake repairs without experience working with electrical equipment. It is important to soberly assess your strengths and, in case of the slightest doubt, contact a repair shop. similar entries from this section