Like any type of household appliance, SMAs often experience malfunctions. One of them is that the washing machine does not fill with water. Why this happens and what to do will be discussed in the article.

In fact, there are many reasons why breakdowns occur, and timely identification of the main factor that led to the breakdown plays an important role. Based on exactly why this happened, the final decision on further actions is made. Practice shows that in most situations the problem is solved within a few minutes.

Codes and signals of this malfunction for various models of washing machines

Depending on the specific model, the washing machine may have certain malfunctions. In this case, you need to find instructions from the manufacturer to find the error and fix it as soon as possible:

- On models of the brands Hansa, Candy, Ardo, Kaiser and Asko, code E appears. It means that the error is primarily related to the set of a specific water level.

- H4 often appears on Beko products, which indicates a closed valve that fills water.

- Siemens and Bosch devices often suffer from error F02, which indicates a lack of water entering the drum.

- On Electrolux and Zanussi units, an error often occurs during the process of filling the tank with liquid, and it is written E Filling in this case takes too long. Error E13 is also common, in which the water level begins to drop due to a leak.

- In Gorenje devices, error F2 appears, which indicates that the limit on the collected water has been exceeded.

- LG household appliances often display an IE error, in which it is not possible to draw water.

- In Samsung brand appliances, errors often appear when filling water, and in Whirlpool there is a problem of the machine not filling with water (E10).

- Atlant devices are characterized by simultaneous intake and drainage of water. On their panel there is the inscription “door”, which indicates that the door is not closed tightly enough.

These are not all fault codes in washing machines that do not fill with water, but they are the main ones.

Reasons why the washing unit cannot draw water

There are several reasons why the washing unit cannot draw water. They depend on the specific make and model of the device, as well as the prevailing circumstances.

Water flows into the machine intermittently

If the pressure from the water supply is weak, there is probably a problem in the central system. All you need to do is turn off the unit and wait until the problems are resolved.You can check the fact that this is precisely the reason: when you open the taps, the water does not flow or flows, but weakly.

The inlet hose or filter is clogged

To make sure that this is the case, you need to disconnect the hose and filter, and then inspect these devices and blow them out. If there are blockages, you need to rid the units of debris and rinse them with a stream of running water.

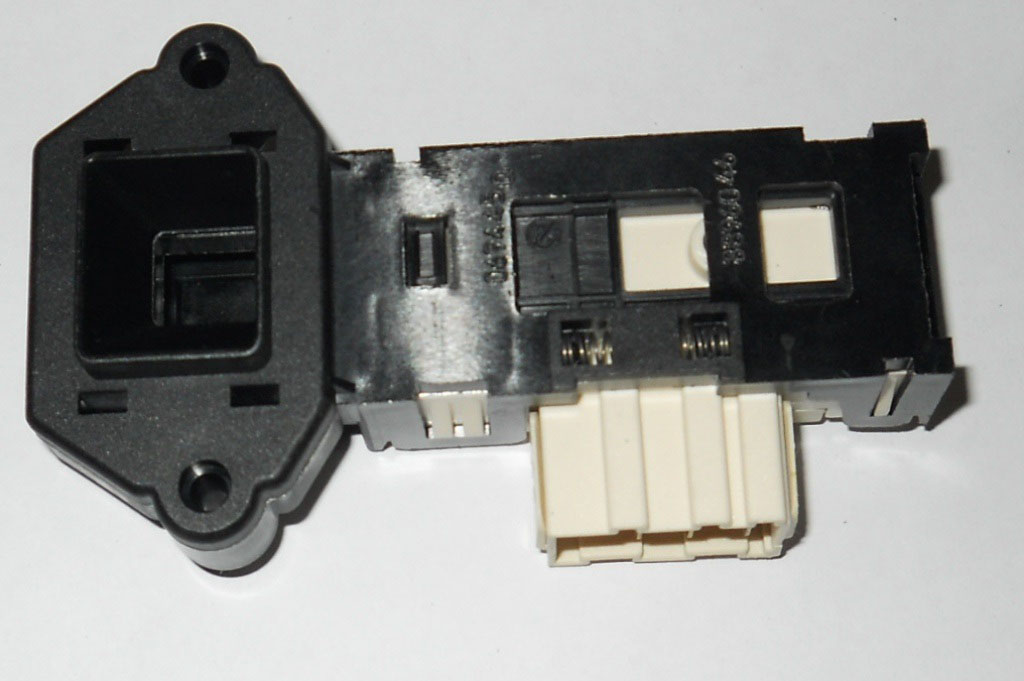

Malfunction of the hatch locking device

washing machine UBL module

If the UBL fails, at the very beginning of the wash you can see a mark on the “lock” icon. This element provides full protection of the device from opening during operation, because at high speeds there is a risk of injury. If the locking device does not work, the washing machine simply does not start to function. All that needs to be done in this case is to replace the hatch locking device.

Problems may also affect the door itself. When closing it, you need to wait for a click when the latch enters the housing. If it is not there, this indicates that the door is not closed completely. In this case, the signal is not sent to the control unit, and there is no water flow into the drum. There may be several reasons for this phenomenon:

- loosening of the hatch hinges, due to which the tongue cannot be inside the latch;

- damage to the tongue or its displacement;

- deformation in the area of the rubber gasket;

- problems with the guide part, which is usually made of plastic.

If the door latches normally, but there is no second click, it is likely that the hatch control system or board has failed.Sometimes door hinges may become warped due to prolonged exposure to vibration, in which case they need to be replaced. Along with this, the lock often fails. It is inexpensive, and replacement work can be organized independently.

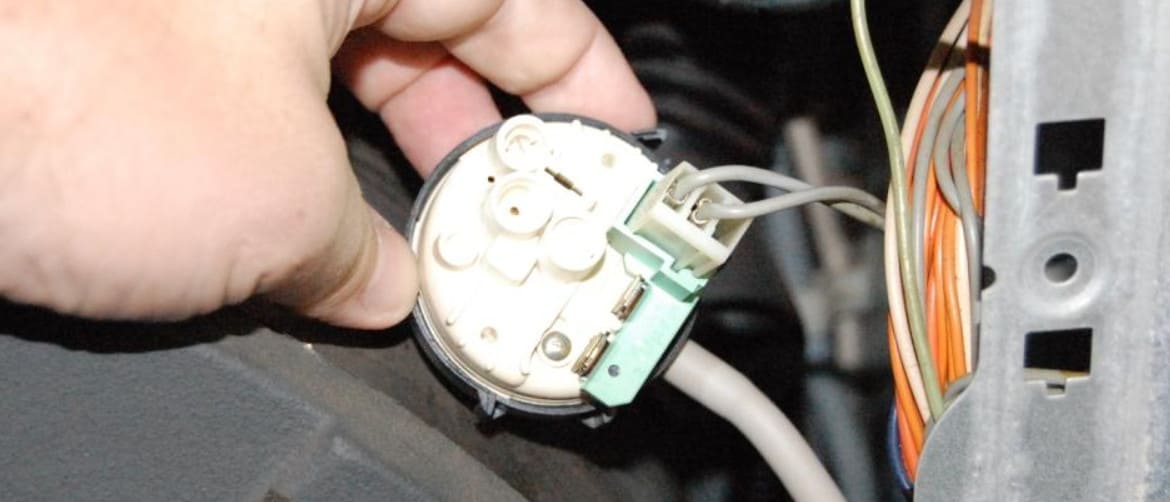

Pressostat malfunction

This is a kind of pressure sensor that allows you to determine the level of water in the tank. It is not difficult to find the pressure switch on the panel; to do this, you need to remove the top cover of the housing part. The part itself is usually round.

The pipe, which is active together with the sensor, transmits air pressure in the tank area directly to its membrane. When this part is filled with water, pressure increases due to the displacement of the air mass. As soon as the value reaches the required level, a signal is received from the pressure switch and the water supply is suspended.

In order to check and replace the part, it is necessary to disconnect the pipe by loosening or completely removing the clamp. Then a check is made for blockages, damage and kinks. If everything is normal, you need to attach a part of another hose that has a similar diameter to the sensor area, and then blow into it. If the pressure switch is working properly, characteristic clicks will appear. If they are missing, the part requires replacement.

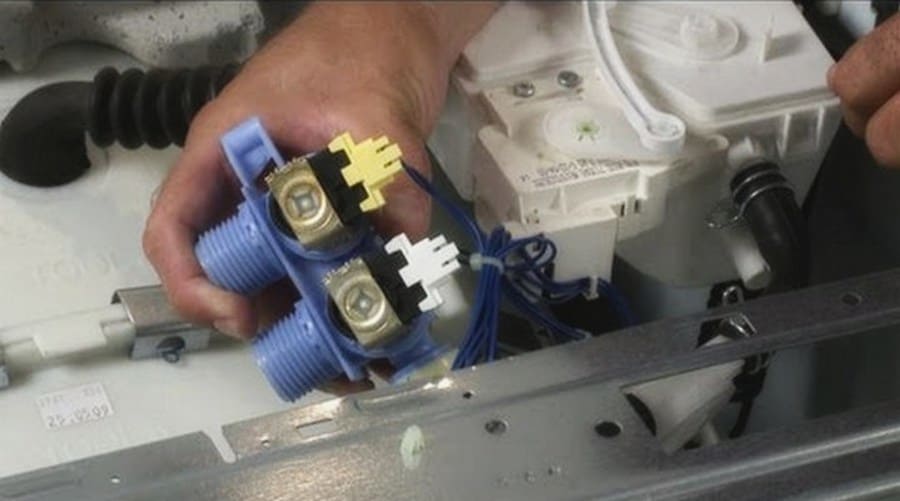

Water supply valve failure

The flow of water into the washing machine traditionally occurs under pressure exerted from the water supply. The opening of this process occurs due to the valve, which receives a signal from the module. If there are any malfunctions in it, the machine cannot “physically” draw water. All that needs to be done in this case is to replace the valve.You can do this yourself. It is necessary to turn off the power to the device, open the cover and disconnect the pipes. Then all that remains is to unscrew the fasteners and bend the latches if there are any. After this, you can remove the valve.

Traditionally, this part consists of electromagnetic-type coils and valves designed to admit liquid. In many modern models, the valves are equipped with two control coils; they distribute the process of water flow into separate blocks.

As for the coils, their integrity can be checked quite easily. When testing using a multimeter, the resistance level should be 2-4 kOhm. If there is a break or short circuit, the part requires replacement; its cost, as already noted, is low.

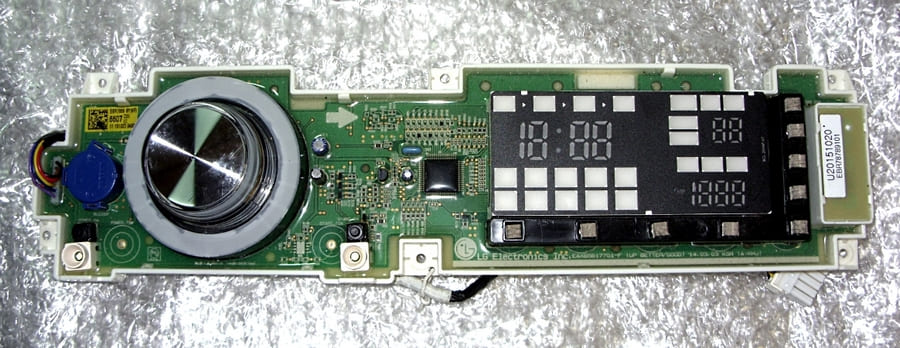

Control unit failure

The control unit is the main unit due to which the machine works properly. If it experiences problems, it can cause multiple systems to fail at the same time. Only an experienced and competent technician can handle diagnostics and repair work.

The fact is that the electronics of washing equipment are characterized by an increased level of sensitivity to a huge number of factors. Therefore, during the operation of the unit, it is necessary to follow a set of certain rules, for example, maintain a certain level of humidity in the room (up to 60%). If it is too high, it leads to problems with electronic boards, damage to wiring connection areas, electrical circuit integrity, etc.

Machine tank leaking

This trouble is unexpected, and the machine fills and immediately drains water.This phenomenon may occur due to fluid leakage due to problems in the integrity of the tank. In a number of situations, it will be necessary to urgently de-energize the household appliance and immediately drain the water from the tank. If a new type of unit is used, it has the “Aqua-stop” option. To fix the problem, you will need to completely disassemble the washing machine, as well as seal the tank.

Along with the reasons discussed above, several other common factors can be taken into account:

- the machine does not respond to the command to draw water due to a breakdown of the control system, the module needs to be “reflashed” or replaced;

- there is no activation of the lock lock, all you need to do is check the tightness with which the door fits, as well as the quality of fastening of its hinges, then press the element tightly until a characteristic click appears;

- problems with connecting wires or their insulation; to identify and solve the problem, you need to inspect and test the tester for breaks and short circuits of all electrical wiring, as well as restore integrity in the event of its loss;

- lack of operation of the filling valve (requires checking the operation, as well as restoring the wires that are used for connection, cleaning the contacts, changing the faulty valve);

- breakdown of the electric door lock (you need to ring the winding, check the condition of the contacts, clean them if necessary);

- breakdown of the valve activation relay (unfortunately, this part cannot be repaired, so it will need to be replaced);

- problems with the board (for example, if a large amount of moisture penetrates into it);

- lack of water in the water supply (this is the most common reason why the washing machine refuses to fill with water fully; most often you need to pay attention to this aspect);

- breakdown of the pump, on which the operation of the entire mechanism depends, the element requires regular testing;

- making mistakes in connecting the drainage system (if such a malfunction occurs, the device cannot drain old water and, as a result, draw in new water).

If the program is activated, but you cannot hear the liquid entering the tank, you need to restart the equipment, i.e. turn it on and off. You can also try checking the pressure, opening and closing the hatch part. These are not all the reasons leading to the lack of water supply in the washing machine, but they are the main ones.

Methods for identifying breakdowns

Before looking for the cause and method of solving the problem, you need to make sure that the breakdown actually occurred in this area. First you need to check a few things:

- Presence/absence of failures in the washing program. At the start, you need to familiarize yourself with the mode in which the product operates, and then try canceling the wash. If there are no changes, you need to reboot the unit by turning it off from the network for only 10-15 seconds.

- Puddles on the floor. If puddles appear under the unit, you need to conduct a thorough inspection, and do this from all sides. Most often, the problem is leaks in the tank area or deformation of the pipe in the housing. Sometimes the dial hose may break, and the fitting also often comes off.

- Availability of liquid for supply in the tap. After this, you just need to check whether there is water in the apartment in principle.In its absence, the problem will be solved when it appears. It is also possible that the tap was turned off, in which case you just need to turn it on.

- Check the door and filtration system. It may also be that the door is not closed tightly enough and the machine cannot operate fully.

- Look at the heating element. There is a high probability that it has burned out. This will be evidenced by its unnatural appearance.

If we talk about other faults, it will be extremely difficult to determine them. The fact is that not every person in the house has devices designed to determine the resistance level of a magnetic coil or supply a voltage of 220 V. Therefore, if the reasons for the breakdown described above are excluded, it is worth contacting specialists who will carry out comprehensive diagnostics and prescribe repair measures.

In addition, in a number of situations it is possible to avoid disassembling the case. In some brands, for example, Ariston, Samsung, Indesit, etc., you can determine faults without disassembling the case. For example, you can simply check the hose or filter and clean it. In other situations, unfortunately, you cannot do without opening the case.

To ensure that breakdowns occur as rarely as possible and do not turn into an annoying surprise for the owner of the washing machine, it is recommended to constantly monitor its general condition and follow the operating instructions. Probably, the lack of water filling indicates errors in the operation of the washing machine.

Here are the main points to consider:

- regular cleaning of the washing machine - we are talking not only about the drum, but also about the internal elements;

- no use of large amounts of detergents, because they can harden on the tubes and prevent easy passage of the liquid;

- periodic cleaning using citric acid or special-purpose powders, this approach will avoid the appearance of scale, as well as premature failure of the heating element.

Thus, instead of frantically looking for ways to eliminate breakdowns, it is recommended to prevent them. This is not difficult to do if you follow the simplest principles of operating a washing machine.

Trouble-shooting

In a number of situations, if the breakdowns are minor and do not require specialized work, you can solve the problem on your own. The first thing you should do is clean the hose, filter and valve, and also deal with problems in the water supply system and pressure switch. In this case, the procedure usually looks like this:

- it is necessary to turn off the washing machine by unplugging it from the socket;

- next - turn off the water supply with the tap;

- after this, work is carried out to unscrew the hose;

- then you need to look at the light, wash it under the pressure of running water to see problems, if any;

- take out the filter element and wash it too;

- unscrew the bolts from the back and remove the cover from above;

- loosen the fasteners using pliers, disconnect the hoses and remove the valve element;

- attach it to the hose area and start the water: it will be delayed by the operating mechanism; if a leak appears, this is a clear sign of a malfunction;

- gradually connect the terminals to each of the valve contacts: if the resistance is less than 2 kilo-ohms, the part must be replaced urgently;

- Next, you need to check the water level sensor; it probably has damage in the housing area;

- after this, it is necessary to clean the metal contacts using a cotton swab, which is pre-moistened in alcohol;

- the pressure tube is removed and washed under running water;

- the hose is sent back, the tap is opened, the washing machine starts again.

If the device refuses to fill with water, and the software display contains information about errors, the device must be urgently taken to a service center so that a specialist can look at it and make a “diagnosis”.

Why does my washing machine take up water slowly?

If the water is drawn extremely slowly or does not want to flow at all, the first thing you need to do is check the pressure indicator in the tap area. It is important that the stream is powerful enough and not barely flowing. If the pressure is good enough, you need to go further in this direction. Namely, remove the lid from the top, turn on the machine in the classic wash mode and listen to whether the liquid fill solenoid is working.

If the characteristic sound of an electromagnet is heard, this indicates that the controller is providing a command to fill. That is, the valve operates to open, but there is no water.

After this, you need to prepare the water supply valve for closing and carefully unscrew the hose from the pipe area. To do this, it is advisable not to use tools and unscrew by hand, because The element is made of plastic and is quite fragile.All that remains to be done is to carefully pour water into the container that has been previously prepared. If she went, everything is fine with the hose and tap. If not, you need to contact a specialized service center to troubleshoot.

Tips to help avoid this breakdown

In order for washing to take place without any problems with water pressure, it is necessary to regularly carry out preventive measures. An important role is played by following certain recommendations, with the help of which it will not be difficult to prevent breakdowns:

- You should always pay attention to the sounds that the device makes. Any changes should alert you. This approach will allow you to identify the problem in a timely manner and avoid large financial expenses later.

- It is unacceptable to start the unit “dry”. It is imperative to check the taps for the presence of water, and also open the hose shutoff. Only after this you can start loading and washing.

- After every 10 washes, the rubber seal and the hatch door must be thoroughly cleaned. If you ignore this recommendation, a breakdown may occur unnoticed and will not be covered by the warranty.

- An increased level of humidity should not be allowed, otherwise the performance of the board will be at zero, and you will need to invest a lot of money in its restoration.

- It is also recommended to explain to young children the consequences of playing with the programmer during the washing process. Compliance with safety precautions is required from all family members without exception.

By taking into account all these rules and principles, you can significantly extend the life of your washing machine and maintain 100% of its functionality even when it becomes obsolete.

Conclusion

An automatic washing machine is a fairly simple mechanism, so complex breakdowns occur quite rarely. If water stops flowing, you need to find the causes of this problem. All of them are described in this article, and if suddenly nothing works, you should definitely contact a service center.

Practice shows that most often the problem is failures in washing programs or rupture of hoses and pipes. Sometimes there may be no pressure, or the hatch may open. In any case, there is no need to panic. Firstly, repairs are quite easy and do not require significant effort. Secondly, parts for SMA are usually inexpensive.

Instead of looking for the causes of breakdowns and ways to eliminate them, it is recommended to prevent malfunctions. There are several ways to do this. But it is best to simply operate the unit correctly in accordance with the principles of the instructions, and also follow safety precautions. In case of the slightest changes, it is recommended to carry out all checks yourself or contact a service center. The sooner repairs begin, the cheaper it will cost in the end.