If the water and light were not turned off, and the washing was completed before the time specified by the program, and the hatch or door does not open, one of the reasons is that the washing machine does not drain the water. In top-loading brands, you can forcefully unlock the hatch, open the drum, scoop out the water and remove the laundry. If the water does not drain in front-loading machines, you will have to find a way to drain the water or call a repairman to your home.

Reasons why water does not drain from the washing machine

The washing machine does not drain water on its own for the following reasons:

- blockage in the sewer pipe;

- the drain hose or filter is clogged;

- a foreign object has entered the pump;

- airing or failure of the pump;

- reduction in pump power during long-term operation (water does not drain at a given length of the drain hose);

- breakdown of the water level sensor (pressostat);

- malfunctions or breakdown of the control module (programmer).

In modern washing machines, if an emergency occurs, an error code appears on the display with the cause of the problem. The decoding of the codes is in the instructions from the manufacturer.

| General error codes (no water draining due to blockages in the drain system or pump malfunctions) in washing machines from popular manufacturers | |

| Zanussi | E21 |

| Atlant | F4 |

| LG | O.E. |

| Candy | EO2 |

| Samsung | E2 |

| Indesit | F05 |

| Ariston | |

| Bosch | F03 |

Do-it-yourself troubleshooting

Before you start troubleshooting the problem yourself, you need to turn off the power to the washing machine and turn off the water supply tap.

Forced drainage of water when the drain is not working

Washing machines manufactured by LG, Bosch, Siemens, Samsung have an emergency drain option. The hose is located in the lower right corner on the front side under the hatch. Before starting the emergency drain, you need to remove the hose (the hatch does not have to be opened all the way), open the faucet or remove the plug, depending on the model.

If the model does not provide emergency drainage, water can be drained in the following ways:

- directly - open the lid (in models with vertical loading and scoop out the water);

- removing the drain filter - used when there is a small volume of water (look through the window for front-loading models);

- through the drain pipe (corrugated hose connecting the tank to the pump) - disconnect from the pump;

- disconnecting the unit from the sewer pipe (only if the sewer is clogged).

The best option is to scoop the water from the tank yourself. If the water does not drain after disconnecting the pipe, which is free of contamination, the inlet of the tank is clogged.

Attention! If the model does not provide for emergency drainage and there is no certainty that any unit is blocked, it is advisable to leave 3-5 liters of water in the tank. Then disconnect the hose from the sewer pipe and start the machine in water pumping mode. If the rest of the water from the tank comes out under pressure, there is a blockage in the sewer pipe at the junction, everything is in order with the machine.

If the pressure is jerky, a little dirt has gotten into the drain hose. In this case, clean the sewer by first placing a container under the hole from the hose connection. Do not connect the hose to the sewer. Pour water into the machine to thoroughly rinse the disconnected hose. Before disconnecting the hose, stock up on several pieces of rags - water may come out from the clogged hole.

In frontal models, before opening the hatch, the washing machine must be tilted back at an angle corresponding to the water level, which can be seen in the window. To ensure maximum safety of the machine’s mechanisms, 3 people are needed: two fix the tilted machine in the corners, the third opens the hatch and scoops out the water. It is dangerous not to fix the unit in an inclined position - damage to the casing and or its fasteners may occur. It is not practical to remove blockages from built-in front washing machines; you can damage the unit and disrupt the communication system of nearby built-in appliances.

Cleaning the drain filter

Do not clean the drain filter when the tank is full. After draining the water from the tank, remove the lid fastening at the bottom on the front of the machine using a flat-head screwdriver. When removing the fastener, do not use much force. In addition to damaging the fastening element, the latch can be damaged. Unscrew the filter counterclockwise.If it jams, try to move it a little clockwise. If it doesn’t work, use pliers without squeezing your lips too much. If the filter does not unscrew, the grooves are dirty, you need to feel the circumference and find the protruding area. Don't put any effort into it. Use pliers in the area opposite to contamination. Make sure that when dismantling, the fasteners do not press on the protruding area. Otherwise, after installing the filter, there will be suction. This applies to all mounts, regardless of model. It will be easy to unscrew the next time.

Rinse the filter under running water without pressing too hard. If the thread is dirty, lightly pick it out with your fingers, wipe with a damp cloth, the filter should fit easily.

Inspection of the pipe

To get to the pipe, you need to remove the back cover. Inspect thoroughly before disconnecting. If the plastic plug gives in under your hands, try moving it, replacing the lid, adding water, and selecting the pumping mode.

If the plug is hard, disconnect the pipe from the empty tank and pump, carefully push the plug, wash the pipe with running water, put it in place, secure it, pour 2-3 liters of water into the tank, start pumping mode.

To disconnect the pipe, you need to unscrew the bolts and remove the clamps with pliers. Do not use a screwdriver with a different number of edges than the bolt head. To avoid leakage, make sure that the clamp clamps the pipe tightly, but does not deform it.

Checking the condition of the pump impeller

If you hear a deep humming sound when pumping water, the pump impeller may be jammed. In modern washing machines, the washing process is interrupted if the impeller does not rotate. The display shows an error indicating a pump problem.

The impeller is located in front behind the filter. Try to scroll it manually. If a foreign object is stuck, remove it. If hair gets tangled in the blades, hold the fur with one hand and carefully remove it with the other. Do not rush, so as not to unbalance the mechanism or bend the blades. A working impeller should rotate jerkily.

Checking the drain pump

To check the serviceability of the pump you must:

- completely empty the tank of water;

- remove the drain filter;

- start the pumping or spin mode;

- watch the rotation of the impeller.

If the impeller, which was previously manually checked, does not rotate, the problem is in the pump.

Attention! If the model provides a pumping mode as a separate function, you should give it preference. When pumping out, only the pump works, the drum is not used. If the pump is running, turn it off immediately.

Testing the winding with a multimeter does not indicate mechanical failure. Replacing the winding reduces the reliability of the device. The cost of the winding is on average 50% of the pump price.

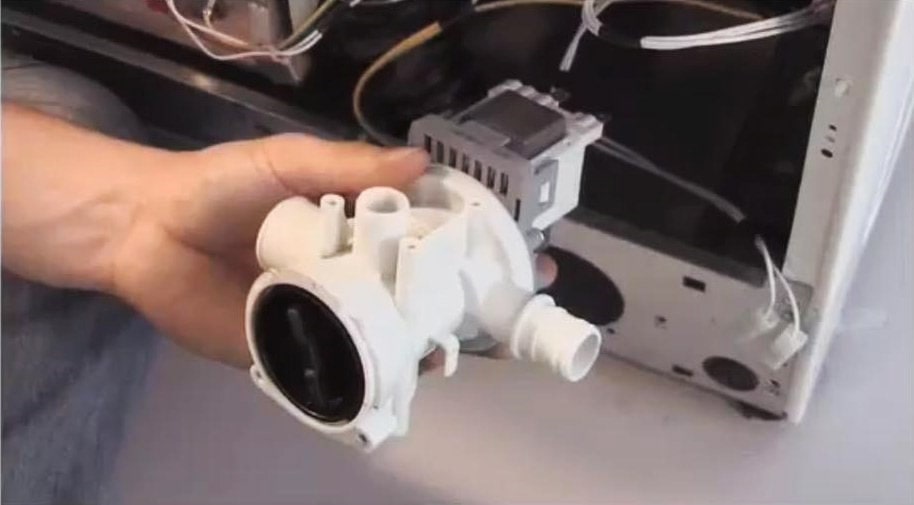

Replacing a faulty pump

You must purchase a sump pump for the same model or line. Otherwise, the software of modern washing machines may prevent the pump from starting even if the voltage, amperage, and dimensions completely match. If there are no special instructions in the manufacturer's instructions (for Samsung, Ariston, LG, Bosch, Indesit and other popular models), you can buy a standard pump. To avoid emergency situations, it is advisable to buy with the possibility of replacement.

Replacement is carried out according to the following algorithm:

- place the machine with an empty, dry tank on its side;

- it is advisable to drain the water from the filter or hose pipe;

- remove the drain assembly. Let dry for a while;

- disconnect the contacts from the pump, unscrew the bolts, remove the pump;

- install a new pump;

- connect the contacts (the pump runs on alternating current, polarity does not matter);

- assemble the machine.

To check the functionality, pour several liters of water into the tank. Checking the pump on an empty tank causes it to become airy.

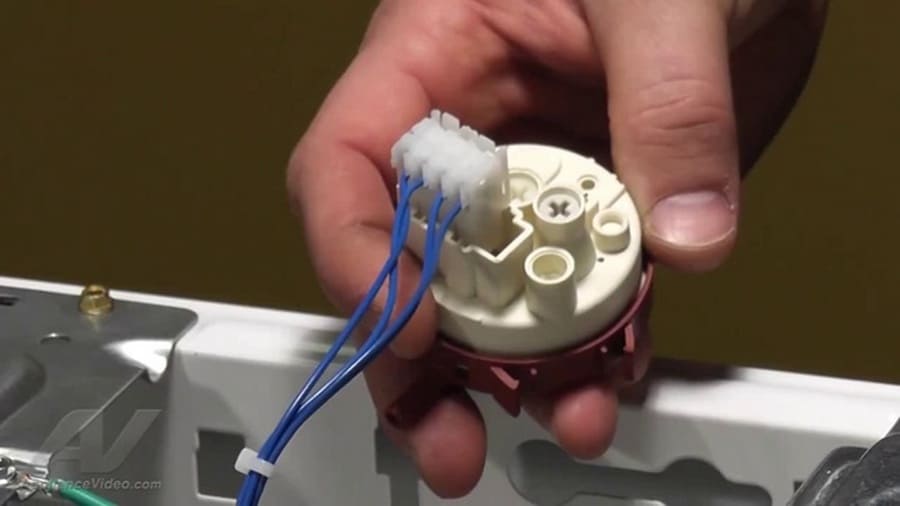

Replacing the water level sensor

It is advisable to check the functionality of the pressure switch before checking the pump. In modern washing machines, if a signal from the pressure switch is sent to the software board indicating that the water has been drained, the pump will not start.

In new type machines, the corresponding error code is displayed on the display. In old washing machines, failure of the pressure switch is determined by the following signs:

- water intake does not stop;

- The washing process is interrupted before the rinse cycle.

The sensor is located under a small panel on the top near the back cover. Typically, the panel is secured with two hex bolts. After unscrewing the bolts, it needs to be moved forward a little. Before dismantling, take a photograph of the location of the contacts so as not to confuse the polarity when reinstalling. Then carefully disconnect the contacts, unscrew the fastening screws, and disconnect the tube from the body. To check if it is working properly, blow lightly into the tube. The working pressure switch will click 2-3 times, depending on the model. Next, install the sensor in place and check the contacts with a tester, while blowing into the tube. If after blowing the multimeter detects the contacts closing, the device is working.

Attention! You need to buy a pressure switch of the same model as the washing machine.

Replacing the control module (programmer)

If all components are working properly, the software module may break down.Due to the complexity of dismantling and installation, it is better to entrust repair of the programmer to a specialist.

In case of failures, turn off the power to the unit for 15-20 minutes and turn it on. This time is enough to completely discharge the capacitors. If you need to finish washing urgently, run each function separately:

- prewash;

- wash;

- rinsing;

- spin

To wash delicate items, start pumping after rinsing.

What to do if the washing mashine hatch is blocked

In automatic washing machines, after starting the specified washing program, the hatch is locked. If problems arise with draining the water, the full washing cycle cannot be completed normally, and accordingly, the hatch continues to be blocked.

You can forcefully unlock the hatch using one of the following methods; proceed to the next method if the previous one is ineffective:

- de-energize the device and wait 1 hour (unlocking will occur after the thermal plate has cooled);

- pull the cable, the end of which is located near the drain filter;

- pass a wire under the lock. Pull parallel to the hatch in the side direction;

- remove the top cover to gain access to the lock.

When unlocking, do not jerk, gradually increase efforts so as not to damage the lock.

Troubleshooting drainage problems in washing machines of different brands

Each manufacturer has a so-called “Achilles heel” regarding the drainage system. Knowing the shortcomings of popular washing machine manufacturers, you can significantly reduce the time it takes to find the cause of a drain problem.

Bosch

The main feature is a weak pump. Bosch washing machines rarely clog hoses, and the electronics turn off at the slightest power surge. To minimize washing interruptions, allocate a separate 220 V phase for the unit.If there are problems with drainage, first check the impeller and pump. The pressure switch rarely fails.

Indesit

Pay special attention to the pump; there is also a high probability of electronic failures. The fuse may not have time to turn off the programmer during voltage surges. It is recommended to connect through a stabilizer designed for operation of high-ampere devices.

LG

First of all, check the drain filter, it often gets clogged. This feature allows you to extend the life of the pump. The manufacturer recommends cleaning the filter after each wash. LG washing machines are distinguished by high-quality electronics; it is not necessary to use a stabilizer.

Samsung

The main feature is that after washing in the “Delicates” mode, the program stops after rinsing. The reliability of all Samsung components is approximately the same. If there is no drain, you need to check step by step from the drain filter to the programmer.

Tips for use

Tips will help ensure uninterrupted operation of the unit after warranty service ends:

- Even if you have the proper skills, it is not advisable to install the washing machine yourself. Self-installation is a reason to refuse warranty service.

- Regardless of the model, clean the drain filter at least once a month. If anyone has hair loss, has pets, or washes woolen clothes - after every wash.

- If the instructions recommend the use of certain means, their use is mandatory. Otherwise, corrosion of the internal walls of the tank, drum or the formation of salt deposits occurs. Salts increase electrical conductivity, increasing the risk of electronic failure.

- Never install the unit on an uneven surface - this will cause the units to become unbalanced. Sensitive electronics will start to malfunction after 3-4 washes. Regardless of the floor material and its evenness, place a protective mat under the machine to strengthen the ground, increase vibration, and regulate the temperature.

- Load the drum no more than 80%, and for boiling at +90° - 60%, for washing in a delicate mode - no more than half of the declared weight. Load wool 20% less than cotton. The data sheet indicates the weight of dry laundry. After loading, try to turn the drum manually, if it creaks - immediately unload 1-2 kg!

- Do not load items with a large difference in size, for example, bras and duvet covers; distribute the laundry evenly in the drum - otherwise it will become unbalanced. Before washing, check pockets, disconnect hard removable objects - minimize the risk of damage to the pump, rupture of hoses.

- Conclusion

In modern washing machines, the reason for the lack of drainage is displayed on the display in the form of an alphanumeric code, the decoding of which can be found in the operating manual for the model. Before looking for a malfunction in the main units of the unit, you need to check if there is a blockage in the sewer pipe, disconnect the drain hose from the pipe, having previously removed the water from the tank. The best ways to empty the tank are to scoop out the water or use an emergency drain. Depending on the manufacturer, washing machines have their own vulnerabilities, knowing which, you can save time when looking for a problem in the water drainage system.

similar entries from this section