Often, users become so accustomed to the proper operation of the washing machine that the appearance of the slightest malfunction leaves them completely confused. To prevent this from happening, you should carry out preventive maintenance on time and pay attention to the details of the device’s operation. For example, if a washing machine makes noise during the spin cycle, this should be considered not only as an irritation, but also as a signal of immediate assistance that the device requires.

What is the normal noise level of a washing machine?

Most modern washing machines are characterized by extremely low noise levels. They can be turned on even at night, which is sometimes simply necessary. If breakdowns occur, their operation becomes incorrect and they begin to make noise.

You can distinguish suspicious noise from standard noise by the following characteristics:

- The usual noise intensified, and was joined by a crackling, whistling, rumble or grinding sound.

- As soon as the water fills, the machine begins to make loud and unnatural noise.

- Increased vibration is added to extraneous sound. Sometimes the equipment even begins to mix and “jump”, creating additional noise.

- When draining water, the pump makes strange and very loud noises.

- The sound accompanies all the actions of the washing machine: when washing, spinning, drawing and draining water, and if you simply turn the drum manually.

- Additional signs indicating a malfunction have arisen - disruption of heating and water circulation, problems with spinning.

Just like any other appliance, a washing machine makes some noise during operation. For example, it is considered completely normal if you hear the following sounds:

- A running engine while the drum is rotating.

- The pouring water that the machine collects.

- Drain pump when water is released.

- Drum during spin cycle at high speed.

- Heating water, which resembles a kettle.

- Clicks when automatically switching modes during the washing process.

They should not be a reason for panic and indicate normal operation of the equipment

.

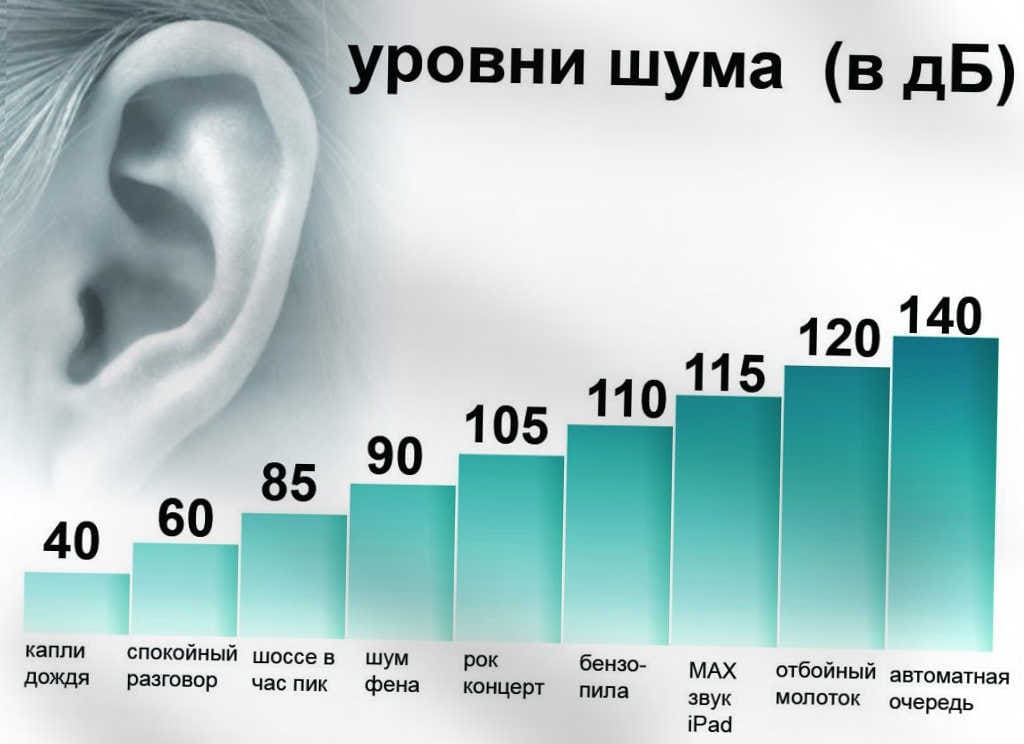

To understand what noise level is considered normal for each specific device, you need to carefully study its accompanying documents. Depending on the model and manufacturer, there may be slight differences. The average for most modern devices is considered to be a limit of 55 dB when washing and 70 dB when spinning. A level of 50-55 decibels is equivalent to background music or standard human speech. On the freeway the noise increases to 80 decibels.Therefore, it is impossible to claim that the device is completely silent.

Causes of noise and their elimination

The first signal that a device is malfunctioning is usually a suspicious and unnatural sound. This may be a grinding, humming, knocking, whistling, crackling or squealing sound. It can occur in individual modes or accompany the entire cycle. It cannot be ignored, since over time this will lead to more serious damage and, as a result, expensive and problematic repairs.

Since the causes of noise can be different, you should urgently diagnose the device and eliminate them.

The washing machine was installed incorrectly

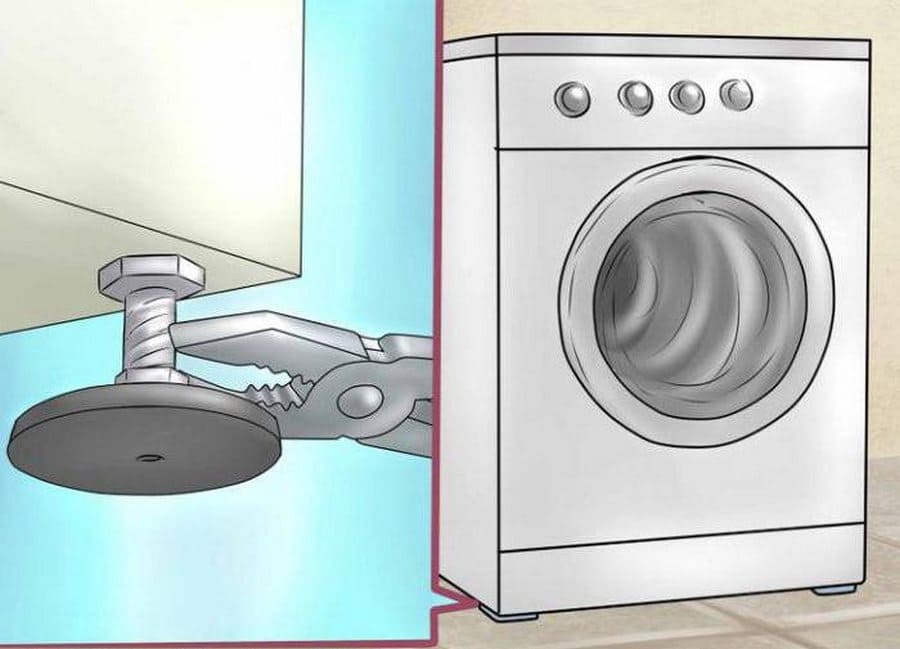

The most common cause of noise is failure to comply with basic installation requirements. As is known, these are:

- Ideally flat horizontal surface. The maximum permissible deviation is no more than 3 degrees.

- Do not place it on too smooth or soft surfaces; do not place wooden blocks, pieces of cardboard or linoleum under the legs.

- Even minor distortions and the slightest wobble are not allowed, as they lead to premature wear of the rotating parts.

The ideal option for installing the device is a concrete floor.

Unfortunately, it can be very difficult to find a completely flat surface, so there are special height adjusters on the legs of the machines. Using a spirit level and tightening each nut accordingly, achieve maximum alignment. After everything is aligned on each leg, the fixing nuts are tightened to the washing machine body.

Drum overload with laundry

Typically, no one weighs the laundry when loading a load of laundry.More often they are guided by the desire to save time and wash as much as possible at one time. This logic leads to equipment overload, which is accompanied by unnatural sounds.

The instructions for each model indicate loading rules and recommended weight for the selected program.

Frequent violation of washing volume standards leads to the following negative consequences:

- Poor-quality work result - the machine cannot cope with the excess volume, as a result of which the laundry is poorly washed, rinsed and spun.

- An imbalance that will be especially noticeable at high speeds.

- Increased load on the motor - as a result, overheating and breakdown.

- Increased water and electricity consumption.

- The occurrence of additional vibrations at high spin speeds.

A one-time overload of the washing machine will most likely not cause serious problems, but frequent repetition will sooner or later damage the bearing, cause breakage of the drive belt and deformation of the seal.

The category of improper loading of the machine also includes too small a volume. One blouse, pair of socks or other weight less than a kilogram causes the empty drum to begin to rattle and vibrate violently. This affects the operation of the motor and the bearing assembly. An underloaded machine will not be able to do its job correctly and will not switch to rinse or spin mode.

If loading is incorrect, the imbalance sensor turns off the automation. This problem can be solved by draining the water and removing or adding laundry.

Foreign object stuck

Often the cause of extraneous noise is a small object caught behind the drum. A similar problem is accompanied by a characteristic hum, grinding and whistling.This happens in cases where:

- Children play and hide their small toys in the washing machine, and the drum is not checked when loading laundry.

- Pockets and accessories are not inspected. Before loading, you should pay attention to the integrity of the locks, straps and straps.

- When loading underwear, clothes with beads, buttons and other decorations, no special bag was used.

Coins, pins or pebbles get caught in the space behind the drum and impede its normal movement. If you do not remove them in time, they can move into the drainage system, block the hose, or even damage the pump.

In this case, you should immediately stop washing and remove the item.

Forgot to unscrew the shipping bolts

Given the presence of moving parts in the washing machine, the transportation process can cause serious damage. To prevent this from happening, they are securely secured using transport bolts. Their number and location are indicated in the accompanying instructions.

You cannot turn on the machine without unscrewing the fasteners, as this will inevitably lead to breakdown. But it happens that one of them was missed due to inattention.

To remove the bolts, you just need to carefully loosen them with a wrench, then unscrew them and put them in a safe place for storage. Each subsequent transportation requires their mandatory installation. To prevent debris and moisture from getting into the holes formed, they are closed with special rubber plugs, which are included in the kit.

Pulley is loose

This often happens if the washing machine is more than seven years old. Elementary wear of parts leads to the appearance of cracks and chips.The problem can be recognized by a sudden difficulty in rotating the drum and a characteristic knocking sound that intensifies significantly during the spin cycle—the drum touches the back wall of the machine.

Often the cause of failure is loosening of the pulley fastenings. This could be a loose screw or a fastening nut on the shaft that has become loose over time. As a result, the machine begins to click clearly.

The reason for the premature occurrence of a problem is often poor-quality assembly or defective fasteners. To fix the problem, simply tighten the loose nut.

Bearings have failed

The rotating parts of the machine operate on bearings. Without them, the rotation process would not be possible at all.

Violation of their operation causes the drum to dangle and is accompanied by a characteristic hum at the moment of spinning. At first the machine rattles, but each time the volume increases.

It is possible to determine for sure that the cause of the noise is specifically the bearings, only after a detailed examination of the internal parts of the device. For preliminary diagnostics, you can try opening the machine door and, lightly pressing the edge of the drum, turn it by hand alternately in both directions. If there is the slightest play, you need to disassemble the device further. In addition, streaks of rust usually appear on the outside of the rear cover of the tank.

Bearings rarely break. Typically, their average service life is 10 years. They are protected from air and moisture by just one seal. Over time, it begins to deform and leak, which inevitably leads to corrosion. Then the part becomes damaged and the entire device malfunctions.

In such a situation, a complete replacement of bearings and seals is necessary.

The counterweight is loose

For stability, weighting the tank and reducing vibration, a special counterweight is installed in the device. It is a heavy artificial weight that is bolted to the top and bottom of the washer. It is usually made of plastic, cast iron or concrete. Moreover, the latter is the most unreliable, since it tends to crumble, break and crack.

As a result of poor-quality fixation, the fastenings of the counterweights begin to become loose over time. This is accompanied by additional vibration, strong rumble and “jumping” of the machine.

To verify this, you need to remove the top and back covers of the machine. If the counterweight is destroyed or cracked, it is replaced with a new one.

The rotation shaft is broken

Often the cause of extraneous sounds may be a malfunction of the promotion system. If the shaft is broken, the drum of the machine does not fit tightly, and the pulley hits the back wall. Accordingly, a rumble occurs, which intensifies at high speeds.

The reasons for shaft wear may be the following:

- Moisture getting into the inside of the mechanism.

- Deformation due to overload.

- Loosening the fastening nut.

- Foreign objects that interfere with the movement of the drum.

- Damage to the water sensor - its false readings can cause the heating to turn on without water, too much or too little water for washing.

- Malfunction of the tachometer - changes the rotation speed, things may be wet and poorly wrung out.

Natural wear and tear of parts occurs over time no earlier than after 7-10 years of intensive use.

Depending on the cause of the problem, you may simply need to tighten a loose nut, replace a sensor or other worn part.

The cuff does not fit the hatch

There is a special rubber seal installed around the washing machine door, which can become deformed, breaking the seal of the hatch. This occurs due to improper installation or adjustment of the cuff size, intensive use, temperature changes, and the use of caustic cleaning agents.

This problem is accompanied by whistling, squeaking and an unpleasant sound of rubber rubbing.

It also happens that a malfunction is noticed when a completely new machine is started for the first time. This is not considered a manufacturing defect and cannot be caused by the consumer. The seal dimensions just don't fit.

Typically, such problems occur in the most inexpensive models. To solve them, you can replace the seal with a new one or try to adjust it using sandpaper.

Counterweights are unevenly distributed

Counterweights can not only be destroyed, but also be displaced from their place as a result of loosening of fastenings. This is very dangerous because a heavy object can severely damage the integrity of the device with one accidental blow.

To fix the problem, just remove the cover and screw it into place. It is important to use moderate force so as not to overdo it and strip the threads. Otherwise, you will have to completely replace the counterweight with a new one.

There is no rubberized mat or rubber pads under the feet

Often the machine is installed on a surface that is too smooth and slippery. Lightweight units are especially prone to moving and bouncing during operation.This leads to unpleasant sound and collision with other pieces of furniture. To avoid this, be sure to place a rubber mat or special pads under the legs. They are made of durable material that does not heat up, does not deform and is not afraid of moisture.

You can find a suitable option in plumbing stores.

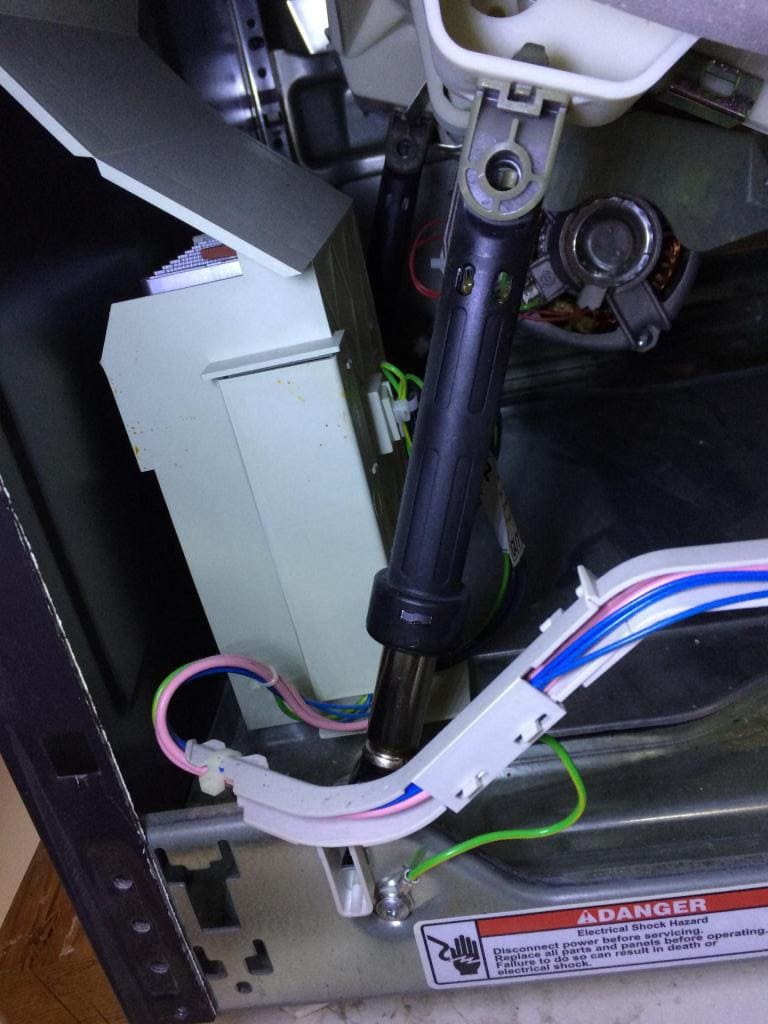

Shock absorber wear

The drum of a standard washing machine averages up to 1800 revolutions per minute. Serious load, amplified by centrifugal force, affects components and contacting parts. To protect them from negative influences, shock absorbers are installed. Together with suspension springs, they dampen vibration of the rotating drum and prevent direct contact of the tank with parts and the metal body. If they weren’t there, the machine would have to be repaired after every wash.

Shock absorbers are located under the main rotating part of the machine and are a kind of supports. During operation of the device, the springs allow the drum to oscillate, moving a very small distance even at high speeds. Thus, the load is not transferred to adjacent parts.

When the shock absorber breaks in the area of the detergent tray, this indicates a leak, which, in turn, provokes rusting and breakage of parts. This phenomenon is accompanied by a characteristic loud knock, which intensifies at high speeds.

It is important to replace both shock absorbers, even if the second one is still normal. Otherwise, the load will be distributed unevenly, and problems will soon arise again.

The spring has flown or failed

Another reason for strong vibration and knocking of the machine may be the spring. The fact is that the washing machine tank is suspended on several springs (2-4). If one of them stretches, bursts or comes off, the tank becomes skewed, the center of gravity shifts, and a knock appears.

To check the assumption in practice, remove the top cover and carefully examine the condition of each spring. If it has come off the fastenings, install it back; if at least one is worn out, everything needs to be changed. This is due to the need for uniform stretching that will position the tank correctly.

Tips to prevent malfunction

Preventing a problem is always easier than fighting it. Experts recommend regular cleaning of the machine and a thorough preventive inspection at least once every six months. In addition, the following simple rules must be followed:

- Linen with small items should be washed in a special bag. Before loading, the pockets must be checked for the presence of small foreign objects that may get stuck in the machine: coins, nails, beads.

- Clothing that is too dirty is first shaken out or even rinsed so that large debris or large amounts of dirt do not clog in the drain systems of the device.

- Use water softeners to protect the heating element from scale.

- Load the amount of laundry recommended by the manufacturer, without deviating up or down from the specified norm.

- It is necessary to comply with the standards for proper installation and connection of equipment.

The appearance of additional unnatural noises is always a direct signal for an urgent inspection of the equipment. The reasons may be different, but most often they are caused by wear of parts or violation of operating rules.You cannot use a faulty machine and put off repairs for a long time, as this can cause more serious problems. Timely diagnosis and troubleshooting will help avoid costly repairs and negative consequences.