If the washing machine freezes on the spin cycle, it means there is a malfunction in its operation. There are a number of reasons why this problem may occur. Some are associated with incorrect actions of the owner of the machine, others – with technical malfunctions. Let's try to figure out how to fix the washing machine freezing during the spinning process.

If the washing machine freezes on the spin cycle, it means there is a malfunction in its operation. There are a number of reasons why this problem may occur. Some are associated with incorrect actions of the owner of the machine, others – with technical malfunctions. Let's try to figure out how to fix the washing machine freezing during the spinning process.

Why did the problem occur?

In automatic washing machines, after starting the wash, many processes occur. First, water is drawn into the tank and the powder is washed away from the prewash cell. Next, the drum of the machine begins to spin slowly. This is how the pre-wash is carried out.

Then the dirty water is drained and clean water is collected again. This water flushes the detergent from the main wash compartment. When the main wash process is completed, the waste water is drained again and clean water is collected. The laundry rinsing process starts.

After rinsing, the machine drains the waste contaminated water. Next, the spin cycle starts. And at this stage problems may arise.

The machine does not spin the drum, and after a short period of time it completely freezes.At best, the machine will display a system error. Then the owners will be able to find out about the malfunction. But sometimes the device does not produce any errors.

First you need to check the simplest reasons that have no connection with technical faults.

Such reasons are usually associated with the fact that the owner of the machine performed incorrect actions.

Such reasons include:

- the drum is overloaded with laundry;

- an item that is too bulky or heavy is loaded;

- The drum of the machine is not loaded enough;

- another washing program was selected (by mistake);

- a foreign object entering the tank jams the drum. As a result, the latter cannot accelerate to high speeds.

When the machine is overloaded, the laundry clumps into a lump and an imbalance in the drum occurs. During the spin cycle, the drum begins to rotate at high speeds and the laundry, knocked into a ball, can damage the drive mechanism. To prevent this malfunction, the machine stops the program immediately. To perform a spin cycle, you need to properly load the drum with laundry.

The situation is much worse when a foreign object gets stuck in the tank. It may jam the drum or damage the tank. In the second case, water will flow out of the machine. Therefore, a stuck object must be pulled out immediately.

If it was not possible to find and eliminate the cause of the freeze at this stage, then you can move on to technical faults. Here, to find and fix the breakdown, you will most likely have to disassemble the machine.

You should not repair the machine yourself if you are not sure that you can handle it. In this case, it is better to entrust the repair work to a specialist. Then you will save time and money.

Drive mechanism failure

Bearing failure is one of the most common breakdowns. It occurs in machines that are heavily worn out. When the bearing is destroyed, the drum of the machine produces a grinding sound of metal during rotation.

It should be noted that replacing the bearing is a very labor-intensive task. If there is no rumble and the bearings are in good condition, but the spin cycle does not start, then you need to carefully listen to the noise made by the machine immediately before freezing.

If the washing machine makes a slight whistle and there is a sharp drop in the rotation speed of the drum, then you need to check the condition of the drive belt.

The stretched drive belt slides along the pulley when the drum speed increases sharply, causing the revolutions to drop. The stretched belt needs to be replaced with a new one.

This is done as follows:

- The washing machine is disconnected from the power supply and communications.

- The unit is pulled out to a place where it will be convenient to work with it.

- The back wall of the machine is dismantled.

- Remove the stretched drive belt. To do this, take it with one hand and turn the drum pulley with the other hand.

- Put a new belt on the electric motor pulley. Then slowly rotate the drum pulley and put the belt on it. Then you need to make sure that the belt fits well on the pulleys.

- Reassemble the machine in reverse order.

Engine malfunction

If the drive mechanism is working properly, then you also need to check the tachometer and electric motor of the machine. A brushed motor often becomes weaker over time due to wear on the carbon brushes.

A weak motor is not able to accelerate the drum to high speeds at which the laundry is spun. In general, you need to check the brushes and replace if necessary.

This is done as follows:

- The back cover of the machine is removed.

- The drive belt is pulled out.

- Next, you need to disconnect the wires that go to the contacts of the electric motor. It is advisable to photograph their location in advance.

- The screws that secure the motor to the fasteners are unscrewed.

- Next, you need to slightly press the engine forward, pull it down a little and carefully remove it.

- There are small screws on both sides of the motor housing. They fix the brushes. They need to be unscrewed.

- The carbon brushes themselves are pulled out. It is necessary to check how much they have worn off.

It should be noted that if even one brush wears out, both need to be replaced in any case.

Next you need to check the tachometer. This part doesn't break often. But still sometimes it happens.

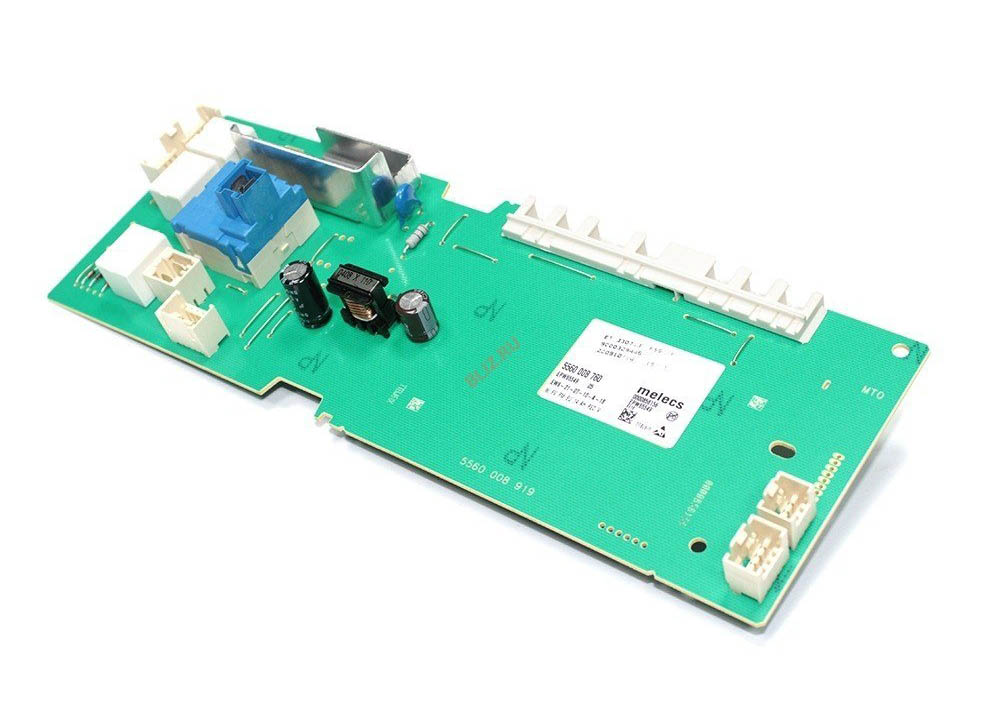

Electronic module failure

A control module malfunction is considered one of the most unpleasant machine breakdowns.

This part has a rather complex structure. Determining the cause of an electronic module malfunction requires knowledge and extensive experience working with electronics.

If you lack such skills, it is better to contact a specialist.He will be able to determine why your “home assistant” does not wring out the laundry.

In this case, it is not worth doing independent repairs, since you can permanently damage the electronic module. And this will cause additional financial costs.