Conclusion

Conclusion

It is important for a beekeeper to have all the necessary equipment for working in the apiary. A honey extractor is one of the most important devices for this. This is an expensive device and if you want to save money, you can design it yourself. How to make a honey extractor from a washing machine with your own hands - this will be discussed in detail in this article.

How a honey extractor works

- This device consists of three main units:

- The structure into which the frames with honeycombs will be inserted.

- The container into which the subframes are installed.

The motor and drive mechanism that will rotate the frames.

If you have an old washing machine in your home, you can use what it has to make a honey extractor. Old Soviet-made washing machines used large and durable washing machine tanks made of stainless steel. This material is resistant to water and is easy to clean from dirt.

The washing machine tank will be stationary during operation, and the frame with subframes inside it will rotate.How to make a honey extractor from a washing machine - washer.tomathouse.com

Wash

Exploitation

- Dishwashers

- Purchase

- Accessories

- Miscellaneous

- Reviews

Accessories

How to make a honey extractor from a washing machine

- CONTENT

- How does a honey extractor work?

- How to make a honey extractor

- What to prepare for work

- Device manufacturing process

- Stretcher

Preparing the legs

Installation of fasteners

Shaft installation

Installing a handle for rotating the honey extractor Which drive is betterManufacturing options

How to use a honey extractor

- Conclusion

- It is important for a beekeeper to have all the necessary equipment to work in the apiary. A honey extractor is one of the most important devices for this. This is an expensive device and, if you want to save money, you have the opportunity to design it yourself. How you can make a honey extractor from a washing machine with your own hands will be discussed in detail in this article.

- How does a honey extractor work?

- This device consists of three main components:

- The structure into which frames with honeycombs will be inserted.

- Containers in which subframes are installed.

- The motor and drive mechanism that will rotate the frames.

- If you have an old washing machine in your house, you can use what is in it to build a honey extractor. Old Soviet-made washing machines used large, durable washing machine tubs made of stainless steel. This material is resistant to water and is easy to clean from dirt.

- The washing machine tank will be stationary during operation, and the frame with stretchers inside it will rotate. Under the influence of centrifugal force, honey will splash onto the walls and flow down.A hole with a tap should be made in the lower part of the tank, through which the product will flow into a previously prepared container.

In the simplest version, rotation of the subframes will be done using hand strength. To do this, you need to rotate the handle. Through bevel gears the movement will be transmitted to the frames.

How to make a honey extractor

It will be necessary to manufacture the following components of this design:

It is necessary to equip an outlet for drainage at the bottom of the washing machine tank and install a tap.

The tank from the washing machine will need to be placed on a reliable support and raised above the ground in order to ensure unhindered flow of honey through the tap into a special container.

There should be an axis inside the washing machine tank on which the frames will rotate. A strong metal rod must be used for it, which will experience serious loads during operation.

It is necessary to create metal holders for frames with honeycombs. The subframes must be firmly attached to the central shaft.

- A design is made so that the rotation of the handle can be transmitted to the frames. This is done using two bevel gears. One of them should be larger. It is fixed on the shaft. The second is located horizontally and connected to a handle that a person will rotate.

- The proposed design is not the only possible option, but has a relatively simple design and is available for self-production.

- What to prepare for work

Grinder saw.

Sledgehammer and anvil.

Drilling equipment. A machine or drill can be used for this purpose.

Vise.

Blowtorch.

Welding equipment with electrodes for working with stainless steel.

When creating a honey extractor, you will need professional skills of a mechanic.

Device manufacturing process

It should be borne in mind that although individual components can be made independently, their production can nevertheless be ordered at an inexpensive price from specialized workshops. After this, all that remains is to assemble all the parts into one structure.

A frame with honey usually has dimensions

435 x 300

millimeters. It should fit freely in the subframe. The magazine one is more compact and will easily fit here.

The manufacture of the subframe occurs as follows:

The starting material for the subframe will be narrow metal strips of stainless steel 1 millimeter thick.

It is necessary to prepare four strips of this length: two 52 and two 55 centimeters.

The strips are arranged in the form of a rectangle and connected to each other. To do this, you can drill them and use screws and nuts, or you can fasten them by welding.

In the resulting frame it is necessary to make a large number of small holes and attach a stainless steel metal mesh.

A second copy of the frame with a mesh is made exactly similar to the first.

Next, you need a strip of metal 1 millimeter thick and 4 centimeters wide.It is bent in such a way as to form a channel (to do this, two strips at the edges are bent at right angles; in cross-section, the shape of the channel will look like the letter “P”).

They are making another such channel.

- Two previously made meshes are attached between them. They can be attached by welding or drilled and secured with screws and nuts.

- Steel strips are welded from the bottom edge so that the frame with honey cannot slide down from the subframe.

- Two brackets are attached to the channels on top. They will be needed to attach the frames to the central shaft.

The manufacture of one subframe has been described here; it is necessary to create another one of the same kind.

The reservoir is a stainless steel tank taken from an old washing machine, for example, from a Riga washing machine. Although it is well suited for the purpose in question, there are gaps in it that need to be filled. To do this, make stainless steel patches and weld them. To check the quality of the work done, fill the washing machine tank with water and make sure it does not spill.

Next, you need to equip a faucet through which honey will be drained into the prepared container.

Now you need to take a drill and drill a hole in the side at the very bottom, at the bottom of the washing machine tank. A step drill can be used for this purpose. The diameter should be 25 millimeters.

- Now it is necessary to provide the ability to close the holes when necessary.

- To do this you need to do the following:

- You need to drill a hole in a narrow metal plate.

- The same diameter is made in the wall of the washing machine tank.

In this case, one edge of the plate will cover the hole - and the other will be a handle for turning it. It is recommended to bend the latter slightly so that it is convenient to rotate it.

Preparing the legs

- In order for honey to flow down freely, the extractor must be raised above the ground. To do this, you can make legs that will serve as a support. First, a round base is made from a metal rod on which the washing machine tank will stand. Then the legs of the required size are welded. For strength, metal rods located horizontally are welded to them. The honey extractor tank is placed on the prepared support.

- Installation of fasteners

Now you need to install a crossbar that will run horizontally from above. It requires a metal strip 4 millimeters thick. They make a hole in it in the center. It is needed so that the shaft passes through it.

The length of the crossbar is selected taking into account the diameter of the washing machine tank. Holes are drilled at both ends. The edges are bent at right angles. The same holes are made on the tank. The crossbar is secured with screws and nuts.

Now you need to assemble the structure that will hold the subframes. To increase strength, metal strips are attached crosswise where the mesh is made.

Previously, two brackets were made on the subframes. Holders will need to be attached to them. They are made from metal strip.

A hole for the shaft is drilled in the center of the upper holder. Along the edges it is also necessary to make them to attach to the previously made brackets on the stretchers.

Attaching to brackets on stretchers is done as follows. Studs are made, the length of which is slightly greater than the height of the frames of the honey extractor. They are made from a metal rod. It is installed vertically so that it passes through the upper and lower brackets, the holes at the ends of the upper and lower subframe holders.

The studs are pre-threaded and secured with nuts and locknuts. A support is attached to the crossbar on top. A handle will pass through it, which needs to be rotated. It is made from a metal strip. You need to make two holes in it. A handle should pass through them, which will be rotated.

The edges of the strip are bent downwards at right angles. Then their ends are bent to the sides. They must have holes for screws. There should be similar holes on the crossbar underneath them. Screws are threaded through them and secured with nuts.

- Shaft installation,

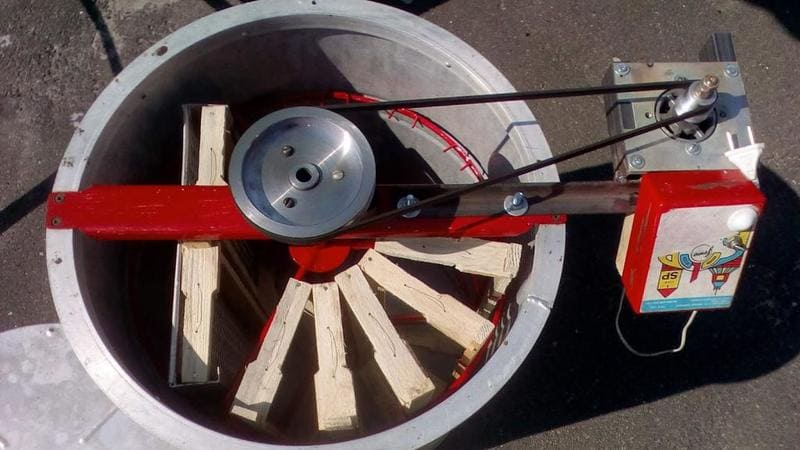

- It will be subject to heavy loads during operation. This is a carbide rod with a thread cut into it. A cone-shaped gear is installed on top. It is secured with nuts from the bottom and top.

- The shaft should pass through the center of the crossbar and through the center of the top holder. The latter is secured to it with nuts on the top and bottom sides.

- Installing a handle for rotating the honey extractor

- You need to thread the handle into the bracket, which is attached to the main crossbar from above through the holes made in it. The handles must have a pre-cut thread onto which a cone-shaped gear is screwed and secured on both sides with nuts.It is important to install it so that the teeth of one gear fit between the teeth of the other.

- This completes the production of the honey extractor.

- Which drive is better

- The simple design of the honey extractor provides for the use of a manual drive to rotate the subframes. However, it is quite possible to supplement a homemade design with a motor. You can, for example, take it from an automatic washing machine. To do this you need to do the following:

- Attach the honey extractor motor so that the axis of rotation is directed vertically. This can be done on the outer wall of the washing machine tub by pointing the axle upward or by attaching it to a crossbar and pointing downward.

- It is necessary to transmit rotation to the shaft through a transmission belt.

- Stainless steel is convenient due to its strength and durability, as well as the fact that it is easy to clean from dirt. To do this, you can not only take a tank from an old washing machine, but use stainless steel sheets to make a similar structure yourself.

- One possible option is to use plastic. On sale you can find durable plastic barrels that can be used for this purpose. The use of such material can reduce the cost of manufacturing the structure in question.