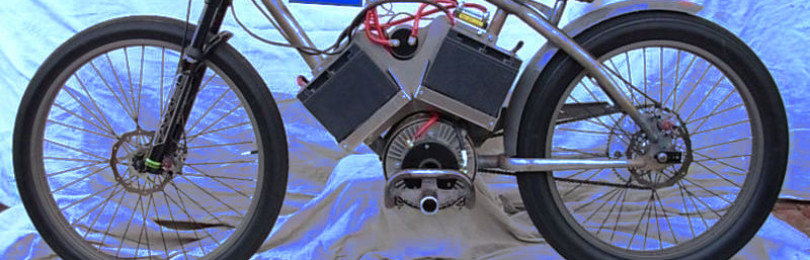

From a huge number of different applications electric motor from the washing machinePerhaps the most original is the transformation of this unit into a bicycle drive. An electric bicycle made from a washing machine sounds more than extravagant, but looks very beautiful.

From a huge number of different applications electric motor from the washing machinePerhaps the most original is the transformation of this unit into a bicycle drive. An electric bicycle made from a washing machine sounds more than extravagant, but looks very beautiful.

Features of the drive

If everything is good in this regard, you can begin upgrading and installing the drive from the washing machine, power supplies and control regulator.

First of all, you need to start with the design and installation of drive parts. It must be said that in order to make an electric bicycle with your own hands from a washing machine engine, you will need a full-fledged workshop with plumbing equipment. At a minimum, you will need a welding machine, a drilling machine and a lathe.

Drive includes:

- Big pulley.

- Modified bicycle hub.

- Electric motor shaft.

- Small electric motor pulley.

- Belt drive from the washing machine.

The most difficult task in this case will be assembling the large pulley.It is almost impossible to find a factory part of the required size, so you need to make it yourself:

- From sheet steel (about 3 mm thick), you need to cut a circle.

- It is best to choose a pulley diameter within 23 cm, but if the machine allows you to make a larger circle, then it is best to do so. This will increase the reliability of the drive.

- Small holes are made in the rear wheel hub, in the spaces between the spokes. In the same way you need to make holes in the steel disk.

- Large diameter holes are made along the edge of the disk; this is required to simply lighten the weight of the part. Otherwise, the entire structure, including the cyclist, will be very heavy, and it is necessary to unload the frame as much as possible.

- Afterwards, you need to weld a 25x5 mm metal strip to the edge of the circle. It is necessary to fasten it gradually by bending the steel strip exactly along the edge. This is a labor-intensive process, since the welding seam must be as smooth as possible.

- Then we fix the part in the lathe and re-process it, getting rid of all possible irregularities.

- This is how a pulley is made. Next, you need to paint the main part of the drive and screw it to the rear wheel.

Frame assembly

The remaining elements of the drive mechanism do not require modification. The small pulley is already on the washing machine motor shaft, and the drive belt is also located here, so you can begin upgrading the bicycle frame.

Before making a frame for an electric bicycle, you need to take into account that the electric motor must be very rigid on it. To do this you need to do the following:

- If the bike initially has a trunk, then additionally you need to weld the transverse pipes. This way you can strengthen the structure. If there is no trunk, it is necessary to weld fasteners for the electric motor from pipes.

- New elements located on the frame must be sanded, painted and dried.

Next you need to install the electric motor on the frame, secure the wheel with the pulley, and check its rotation. The drive belt is tensioned, low speeds are manually applied, and its reliability is checked to see whether it falls off or not. If everything is fine, they begin to connect the electric motor of the washing machine and supply the batteries.

Chain transmission

This transmission method is also often used by home craftsmen. It is visually clear, and there is a huge selection of required parts from ordinary bicycles. As an electric motor, you can use not only the motor from the washing machine, but also any drive that is found in the automotive industry.

This method has certain disadvantages. It must be said right away that upgrading a bicycle using this method will require the owner to have certain technical skills and a fairly deep knowledge of mechanics.

Modernization involves certain changes in the frame design, which reduces its strength. Therefore, it is not recommended to perform this work on bicycles made of carbon fiber or aluminum. This is only suitable for steel products.

But the disadvantages are compensated by many advantages:

- This transmission method is the most reliable and economical of all that exist.

- You can install a stepped gear shift option, which is familiar to many bicycle owners. This allows you to significantly increase the battery life by selecting the required mode taking into account the method of movement or terrain.

- This transmission option makes it possible to use elements already on the bike. This slightly increases the overall weight of the structure. In addition, the efficiency of the drive allows the use of lighter motors and batteries.

- Bicycles that have this particular gear develop the highest speed.

Naturally, in this case there is a huge field for various design solutions. But there are also ready-made components for electric bicycles on sale.

These “constructors” are manufactured in various variations - with the installation of a standard bicycle chain, or with the transmission of rotation using an additional chain with several sprockets.

The structures are equipped with electric motors with a power 360-1650 W, with meals 24 or 36 V. To control the electric drive, controllers are installed, and in electric motors up to 600 W They most often come built-in.

The package contains all the required elements and fasteners, as well as electric drive controls. Installing this drive is easy for any DIYer.

The total weight of the bike is heavier by about 5 kg, but the speed indicators are quite impressive - 45 km/h and higher.

Power supply

First you need to understand whether you can commutator motor from the washing machine to work on direct current? Since the battery, which will be the main source of power for the electric motor of the bicycle, produces direct current, and the washing machine and its elements are connected to alternating voltage (conventional network 220 volt).

Next you need to choose a suitable battery. Certain problems may arise here, since it is required 7-9 powerful batteries that are difficult to attach to a bicycle due to their large size and massiveness.

The best option would be to install 8 small motorcycle batteries that consume 12 Volt. That is, there is tension 96 V. But a problem arises - even these batteries take up a lot of space and weigh a lot.

Therefore, it is most advisable to install them evenly on a bicycle frame, hanging them on the vehicle like a Christmas tree with decorations.

This condition can add problems:

- Sometimes it is necessary to further strengthen the bicycle frame so that it can withstand increased load.That is, this makes the structure more weighty.

- You will need to weld 8 special battery fasteners to the bicycle frame to ensure they are firmly attached.

- In the literal sense, it is necessary to completely cover the frame with wires. This is how the batteries are connected to the electric motor of the washing machine.

- You also need to restore the “beauty” of the vehicle again, that is, repaint the bicycle frame almost completely.

Electrical speed control

To assemble an electric bicycle from a washing machine motor, you need to install a control unit. What you will need:

- AC resistor;

- pulse reduction converter 33.6 kHz;

- measurement resistor;

- controller ATtiny 26;

- transistor like IRFB 33N15D;

- controller IR 2127S;

- smartphone charger;

- 3 LEDs like 10 CTQ150;

- yellow and green diode;

- heatsink from PC motherboard;

- DC/DC converter P 6AU-1215ELF;

- body of the required size;

- automation 6 Amps.

In order for the control unit to work, you need to connect the machine and turn the gas handle. This activates the AC resistor located on the steering section. So the homemade electric bicycle begins to gradually gain momentum, then the green diode on the block turns on.

If the batteries are completely dead or there is not enough charge, the red diode will turn on. Then the electrical circuit is interrupted for a certain time. The vehicle will need to be pushed manually until the battery can be charged.

Electric bike test

The tests were carried out in several stages:

- Controlling a bicycle at maximum speed on a flat road is approximately 30 km/h.

- Driving an electric bike on roads with minor inclines – 28 km/h.

- Driving capacity on a simple, relatively flat road (part dirt, part asphalt) approx. 20 km/h.

Thus, in the latter case, having accelerated to approximately 20 km/h, maintaining this speed, you can drive approximately 28 km on a dirt road on a single battery charge. Moreover, muscular strength is not used.

The engine from the LG washing machine made it possible to drive the vehicle on a flat road with small slopes at approximately 28 km/h, you can drive with a distance 25 km on one battery charge.

Top speed tests prove that a DIY e-bike can reach speeds of approx. 40 km/h subject to a flat section of the road. At the same time, the mass of the rider who tested the electric bicycle was 98 kg.

It should also be added that if you additionally help the electric motor with the help of the muscular strength of your legs, you can easily gain speed 55 km/h. Moreover, the batteries discharge faster, and the charge lasts for approximately 17 km.

To make an electric bicycle from a washing machine drive yourself, you will need a little time, a workshop, and also small material costs. But this is only on the condition that you do not need to buy a bicycle and washing machine parts.

In addition, from a used washing machine you can also construct:

- lawnmower,

- grass cutter,

- router,

- honey extractor,

- Potter's wheel,

- wood splitter,

- concrete mixer,

- irrigation pump,

- lathe,

- juicer,

- circular

- and much more.