During long-term operation of a Bosch washing machine with front or vertical loading, the user may notice that the equipment begins to make extraneous sounds - knocking, noise, and during spinning - a gradually increasing hum. Such signs indicate that the bearings have failed. To carry out repairs, you can contact specialists, but if you know how to change the bearing on a Bosch washing machine, you can replace the part yourself.

During long-term operation of a Bosch washing machine with front or vertical loading, the user may notice that the equipment begins to make extraneous sounds - knocking, noise, and during spinning - a gradually increasing hum. Such signs indicate that the bearings have failed. To carry out repairs, you can contact specialists, but if you know how to change the bearing on a Bosch washing machine, you can replace the part yourself.

Causes and signs of bearing failure

If the Bosch machine begins to make a lot of noise during operation, you can hear knocking and grinding noises that intensify during spin cycles, this indicates the need to replace the bearings. During operation, the seal covering these units wears out over time, and water begins to enter the bearing seat through it. It washes away the bearing lubricant, resulting in increased friction and deformation of the bearing.

To finally make sure of the diagnosis, you need to open the washing mashine hatch, bend the cuff and manually turn the drum or shake it. Significant play will be noticeable.

To replace bearings and seals yourself, you need to assemble a tool and purchase spare parts, as well as prepare your Bosch washing machine for repairs.

Preparation for repair work

The first thing you need to do before carrying out troubleshooting work is to prepare the necessary tools. To replace bearings on a Bosch Maxx 5, Bosch Maxx 4 or other series you will need:

- a set of Phillips and slotted screwdrivers;

- set of socket heads;

- pliers;

- needle nose pliers;

- hammer;

- bit;

- rubber mallet;

- WD-40;

- silicone sealant.

You will also need a basin or other container to drain the remaining water in the washing machine and dry rags.

In addition to the tools, you need to purchase spare parts. Bosch service centers sell special repair kits that include bearings and seals, as well as special bearing grease. In order not to make a mistake when choosing, you need to tell the sellers the brand of the washing machine and model, this is the only way they can select the right set of spare parts as accurately as possible. In addition to service centers, you can purchase replacement parts in a specialized store or online.

If the washing machine has served for many years, it is recommended to first disassemble it, inspect the components, and only then go to the store. In addition to the bearings, it may be necessary to replace other components. It is better to do this right away so that after a while you do not have to disassemble the machine again to replace one or another part.

Before you begin disassembling the washing machine, you need to disconnect it from the network, disconnect it from the sewer and water supply and move it to a spacious place so that nothing interferes with the repair. You need to place one or two tables nearby to put the removed parts on them.

When disassembling a Bosch washing machine, it is recommended to take photographs of each step so that there are no problems during assembly. First of all, this concerns wiring.If the connection is incorrect, a short circuit and contact burnout may occur, which will lead to additional expensive repairs, and in the worst case, to the purchase of new equipment.

Bosch washing machine disassembly

To replace bearings and seals, the Bosch machine will need to be completely disassembled. This process is very similar for different series (Bosch Classixx5, Bosh Avantixx or another) and looks like this:

- Unscrew the screws from the back of the washing machine, move it forward a little and remove the top cover.

- Remove the detergent drawer.

- Unscrew the three screws behind the cuvette and one from the inside that hold the control panel.

- Take a photo of the wiring connection, disconnect the wires, remove the panel.

- Remove the plinth panel located at the bottom of the front of the machine.

- Unscrew the screws located behind it.

- Open the hatch.

- Unclench and disconnect the clamp holding the cuff.

- Tuck the cuff inside.

- Unscrew the screws holding the UBL, stick your hand inside, pull out the locking device, disconnect the wiring and remove the part.

- Lift, remove and move the front panel to the side.

- Disconnect the compartment into which the detergent cuvette is inserted, loosen the clamp securing the hose for supplying detergent to the tank and remove the pipe.

- Unscrew the fasteners, remove the counterweights installed at the top and bottom.

- Take a photo of the heating element wiring and disconnect it.

- Unscrew the nut holding the heating element to the edge of the bolt and push it inward, then pull out the heating element.

- Substituting the container so that the remaining water does not spill onto the floor, remove the pipe going from the tank to the pump.

- Disconnect the wiring, unscrew the fasteners, remove the pressure switch.

- Remove the wiring fasteners, move the wires to the side so as not to interfere with the removal of the tank.

- Unscrew the fasteners and remove the back cover of the Bosch machine.

- Pull the belt to the side and, turning the drum, remove it.

- Unclench the clamps holding the motor wires, disconnect the wiring, unscrew the fasteners and remove the motor.

- Disconnect the pressure tap chamber.

- Unscrew the lower shock absorber mount, disconnect and remove the part.

- Holding the springs, carefully remove the tank along with the drum and pull it out of the housing.

Bearing replacement

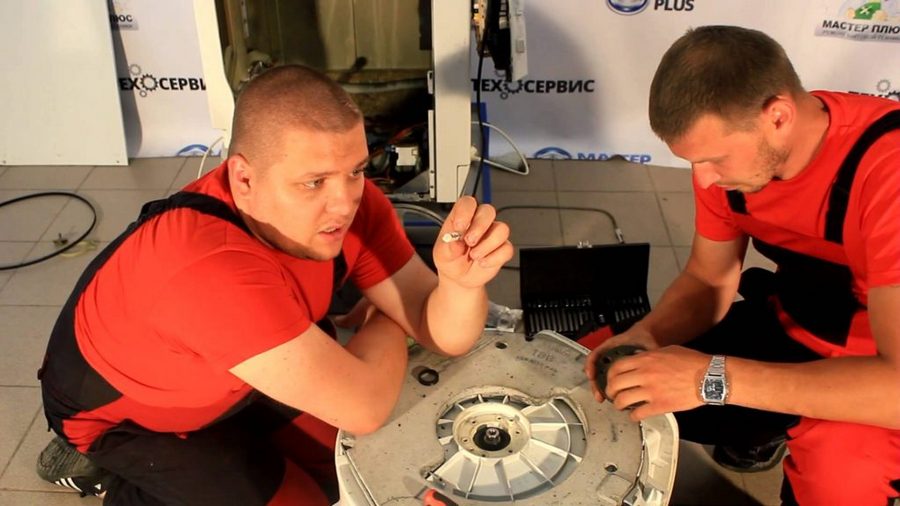

Now you can start replacing the bearing in your Bosch washing machine. To do this you will need to disassemble the tank. On most models of Bosch machines it is collapsible, only on some devices halves of the tank are soldered.

- Turn the tank over with the pulley facing up, unscrew the bolt, remove the pulley, then screw in an old bolt of similar diameter and knock out the shaft using a rubber hammer. Apply blows strictly at right angles so as not to damage the shaft.

- Remove the bolts holding the tank halves.

- Release the latches.

- Divide the tank into two parts.

- Get the drum.

The drum bearings are located at the rear of the tank. Before you begin replacing parts, you must inspect the shaft, bushing and crosspiece for damage. They can be damaged if the machine has been running for a long time on deformed bearings. If a breakdown is detected, the faulty parts must be replaced. Next you need:

- Take a hammer and chisel and knock out first the outer, then the inner bearings. The old seal will be removed along with the second bearing.

- Wipe the seats from dirt and lubricate thoroughly.

- Carefully lubricate and replace the bearing installed on the outside of the tank. To do this, you need to install it on the seat and drive it in with hammer blows in a circle; they should be applied only on the outside of the part.

- Next, the internal bearing is replaced.

- Now a new oil seal is installed. It must be thoroughly lubricated and all voids filled with lubricant.

Reassembling the Bosch machine is done in reverse order. When connecting the halves of the tank, the joints must be thoroughly coated with silicone sealant and allowed to dry after assembling the machine for the recommended time. When connecting the wiring, you must use the photographs that were taken during disassembly to avoid mistakes.

Conclusion

Replacing the bearing on the drum of a Bosch washing machine can be done on your own at home. To do this, you need to know the correct procedure, have the right tools and purchase spare parts. It is worth remembering that if there are doubts about the successful outcome of the repair, it is better to call professionals and entrust them with this task.