When the need for such work arises, you should not immediately contact the service center for help. Almost every user can dismantle a failed element and install a new one in its place. washing machine, if he acts in accordance with the recommendations. The instructions on how to change the plug on a washing machine will definitely be useful to an inexperienced person who is not able to understand the order of connecting the wires. Almost all household appliances operate on electricity using a Euro plug, made without grounding or with it. In the cord, two ordinary cores are replaced by three, which sometimes creates difficulties when replacing the plug. But there are simple ways to repair the wire, and your washing mashine will work normally again.

When the need for such work arises, you should not immediately contact the service center for help. Almost every user can dismantle a failed element and install a new one in its place. washing machine, if he acts in accordance with the recommendations. The instructions on how to change the plug on a washing machine will definitely be useful to an inexperienced person who is not able to understand the order of connecting the wires. Almost all household appliances operate on electricity using a Euro plug, made without grounding or with it. In the cord, two ordinary cores are replaced by three, which sometimes creates difficulties when replacing the plug. But there are simple ways to repair the wire, and your washing mashine will work normally again.

Cord plug repair

Before opening and replacing the Euro plug, it is recommended to make sure that it is damaged. For this purpose, the machine wire plug is removed from the socket, and its body and wire are inspected. Signs of carbon deposits, melting or burning smell will confirm the need for repair work.

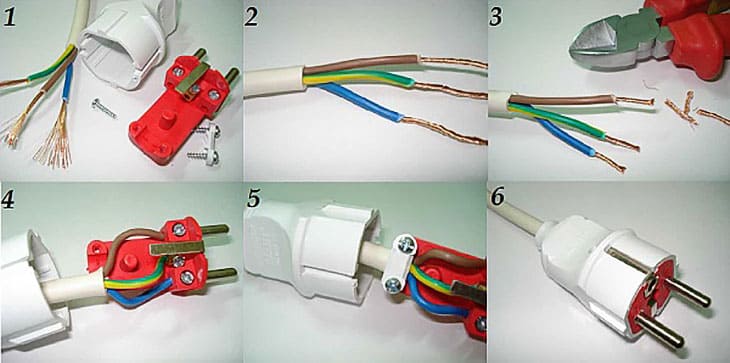

To work, you will need a sharp knife, screwdriver, and pliers. The algorithm of actions is as follows:

- cut off the old element;

- remove the top insulation a few centimeters from the cord;

- we strip each wire;

- we twist and cut the internal cores so that one centimeter of uninsulated wire remains;

- Use pliers to bend the wire ends;

- We inspect each wire. A standard cord, as a rule, comes with three wires - blue or cyan leads to zero, yellowish-green indicates grounding, black, brown or pink wire goes to the phase;

- the wires are connected to the new plug, with the “ground” being brought out to the contact located in the center.

Repairing a simple old plug

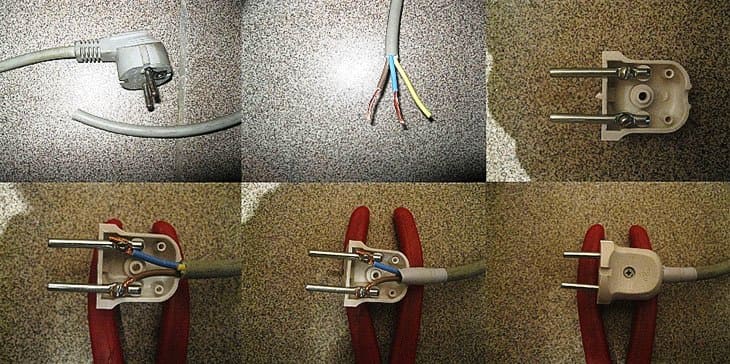

Each automatic washing machine in the modern version it has a Euro plug. But if there is a desire, the European model can be changed by installing a simple old Soviet-style plug. It is recommended to perform the same work if your apartment does not have a ground wire in the electrical circuit. In principle, all actions are almost similar to previous events, but certain features still exist in order to change the fork:

- cut off the plug, unscrew the housing;

- remove the top insulation a few centimeters;

- We strip each wire a couple of centimeters, trim the excess length with scissors;

- At the end of each core we make a ring;

- We connect “zero” and “phase” to the contacts, while the polarity does not need to be specified. If the machine cord has a grounding wire, we simply cut it off - the old-style plug does not provide for its fit.

Is it possible to change the cord?

Quite often, a malfunction of the power cord plug is explained by a short circuit that has occurred, and the original source of the problem is hidden in another place. For example, it may be a power cord that has a breakdown. A similar problem arises as a result of crushing by bulky objects, and external damage caused by a nail or sharp corner also occurs. In this regard, you should not rush to disassemble the plug until the cord has been carefully inspected for cracks, bends or burn marks.

The easiest way to check the functionality of the machine's power cord is with a multimeter. The prepared tester switches to the “buzzer” mode, after which you can ring the cord. As soon as the device detects an electricity leak, it will emit a high-pitched signal.

When testing a circuit whose length exceeds two meters, it is recommended to prepare a second wire and insert it into a single circuit. If there is no spare conductor, there is a second option - the “zero” and “phase” wires are connected at one end of the cord. The probes of the measuring device are connected to the nearest contacts. It should be noted that this verification method has certain advantages:

- in one step, the probability of leakage is checked on both wires connected in a common circuit in series;

- there is no need to find a suitable conductor and build up the circuit.

In the absence of a multimeter, the integrity of the conductor is checked using a universal device made by yourself.To do this, you will need a 3.5 V light bulb, a battery with a slightly higher power, a connector and a pair of connecting wires. The elements are connected in a certain sequence:

- a light bulb is connected to the positive contact of the battery;

- The second contact is connected to a flexible wire equipped with a clamp.

Comparing collapsible and cast forks

The second option is more reliable and features tight contacts connected to pins. Spot welding, soldering and crimping are used in the manufacture of a cast plug. In addition, this plug is sealed.

Unfortunately, it is impossible to disassemble such a fork for the purpose of repair. When fraying at the base of the power cord, the cast plug has to be cut off and a collapsible model installed. You can completely change the cord of the machine, but you will have to partially disassemble it.

But if you are not afraid of difficulties, then it is better to replace the failed cast fork with a similar new one, as it is more reliable in operation.

Conclusion

Note that you can replace the power cord plug on any machine. Indesit, Bosch, Ariston And other brands have no fundamental differences in this matter.